无氧环境和厌氧细菌在自然环境中普遍存在。因为环境中存在广泛的硫酸盐,硫酸盐还原菌 (SRB) 通常被认为是微生物诱导腐蚀 (MIC) 的主要元凶。在SRB存在下金属的腐蚀机理是一个复杂的生物化学过程,先前研究人员针对有SRB参与的金属腐蚀提出了各种机制。阴极去极化理论认为,SRB通过一种叫做“氢化酶”的酶来消耗阴极氢。而Costello[1]的研究表明,H2S是一种由SO42-还原得到的阴极活性化合物。因此,阴极去极化理论仍然存在很大争议[2]。李付绍等[3]分析了SRB对不锈钢的腐蚀规律,研究结果表明,SRB的代谢产物显著降低了不锈钢的点蚀电位。Chen等[4]观察到材料表面生物膜形成和缝隙中硫化物沉积导致电位差增大。Domzalicki等[5]在相似的阴极极化条件下分析了铁素体-珠光体和索氏体微观结构对SRB氢辅助裂解的影响。

关于微生物对SCC的影响仍存在争议。Gunasekaran等[6]报道,微生物可以在低碳钢表面形成保护膜,以抑制腐蚀。Xu等[7]表明,当培养基中缺少有机碳时,SRB利用Fe0氧化释放的细胞外电子作为电子供体,因此对碳钢的腐蚀性更强。Zhang等[8]观察到通过在培养基中加入电子介质可以增强电子传递并加速腐蚀,认为在细胞外电子转移理论下,电子传递控制SRB导致的MIC程度。Xu等[9]提出了生物催化阴极硫酸盐还原理论,阳极反应为Fe0的氧化,阴极反应为生物催化下的SO42-还原。SO42-还原发生在SRB细胞质中,没有物理阴极。鉴于此,本文主要研究SRB存在对不锈钢在模拟海水条件下应力腐蚀开裂 (SCC) 行为的影响规律。

1 实验方法

实验材料是抚顺特殊钢有限公司生产的05Cr17Ni4Cu4Nb (17-4PH) 马氏体沉淀硬化不锈钢,其主要化学成分如表1所示。

表1 17-4 PH不锈钢的化学成分

Table 1

| Value | C | Mn | Si | S | P | Cr | Ni | Cu | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal | ≤0.07 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.03 | 15.0~17.5 | 3.00~5.00 | 3.00~5.00 | 0.15~0.45 | Bal. |

| Measured | 0.04 | 0.28 | 0.51 | 0.021 | 0.027 | 16.0 | 4.15 | 3.40 | 0.30 | Bal. |

本实验用17-4 PH不锈钢均先进行1040 ℃保温1 h的固溶处理。单级时效处理为 (550 ℃×4 h),记为工艺A,相应的试样称为试样A;双级时效处理为 (520 ℃×4 h+550 ℃×4 h),记为工艺B,相应的试样称为试样B;调质+时效处理为 (820 ℃×0.5 h+550 ℃×4 h),记为工艺C,相应的试样简为试样C。3种热处理工艺冷却方式均为空冷。升温速率约150 ℃/min,冷却速率约80 ℃/min。

模拟海水溶液是配制的pH为7.5的3.5% (质量分数) NaCl溶液。含SRB的模拟海水中使用的SRB菌是Desulfovibrio型,并且在美国石油协会推荐的标准培养基中培养。培养基I的成分为:0.5 g/L Na2SO4,1 g/L NH4Cl,0.5 g/L K2HPO4,0.1 g/L CaCl2,2 g/L MgSO4·7H2O,1 g/L,1g/L酵母粉和3.5 g/L乳酸钠;培养基II的成分为:0.1 g/L抗坏血酸,0.1 g/L保险粉和0.1 g/L硫酸亚铁铵。用压力蒸汽灭菌锅在121 ℃保温15 min以进行高压灭菌并空气冷却至25 ℃,冷却后加入经紫外线灭菌的培养基II,完成培养基配制。接菌时,将预先准备好的菌液放在恒温培养箱内 (30±2) ℃活化30 min[10]。

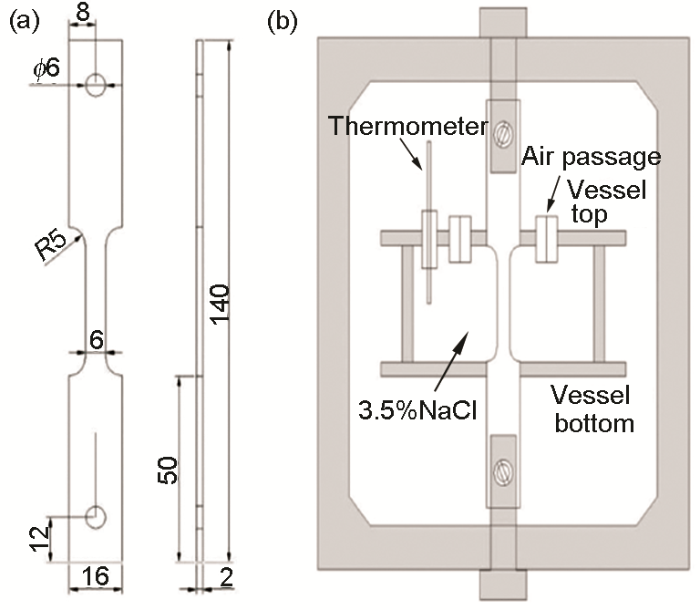

图1

图1

用于应力腐蚀实验的试样尺寸及实验容器示意图

Fig.1

Dimensions of test specimen (a) and schematic diagram of test vessel for SCC experiment (b)

2 结果与讨论

2.1 不同热处理后的组织形貌分析

单级时效、双级时效和调质处理工艺后的不锈钢显微组织如图2所示。结果表明,材料内主要由回火马氏体和少量铁素体及残留奥氏体组成。图2a中固溶处理后直接时效处理的组织中同时存在淬火马氏体和回火马氏体,白色区域为淬火马氏体,黑色区域为回火马氏体[12]。Ziewiec等[13]认为,17-4 PH不锈钢是铁素体的冷却模式,在冷却过程中相变的顺序为:莱氏体→δ铁素体→γ奥氏体+δ铁素体→马氏体+δ铁素体。有研究[14]表明,组织中还有少量的残留奥氏体和第二相析出物,主要为Cr7C3和fcc-Cu相,弥散析出的细小fcc-Cu相和位错交互作用产生强化。图2b中双级时效处理后,白色组织区域减小,黑色组织区域增大,组织中部分淬火马氏体转变为条带状连接成片状的回火马氏体。在双级时效处理之后,回火马氏体均匀地分布在试样中。图2c中调质处理后,组织中马氏体均匀细小,层片状位向关系明确。晶界相互连接成网状,将主要由马氏体和残留奥氏体组成的晶粒包束在其中,这种组织形态与钢中产生较多的残留奥氏体有关。

图2

图2

经不同工艺处理的17-4PH不锈钢的显微组织

Fig.2

Microstructures of 17-4 PH stainless steel treated by different processes of single-aging (a), double-aging (b) and quenching and tempering (c)

2.2 不同测试介质中的力学性能

2.2.1 应力-应变曲线分析

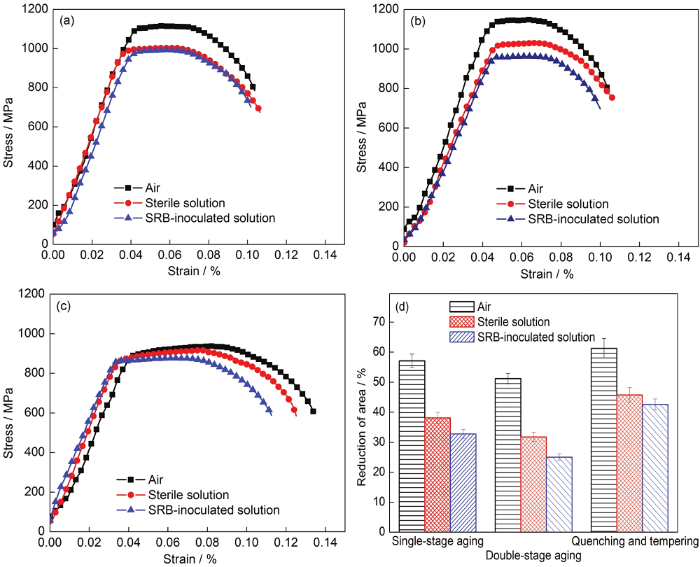

图3为不同热处理工艺的17-4 PH不锈钢在无菌和接种溶液中的应力-应变曲线。以单级时效、双级时效和调质处理试样在空气中的应力-应变曲线为参考来评价无菌和SRB接种溶液中的SCC敏感性。在无菌溶液中,双级时效过程后试样的屈服强度高于单级时效处理和调质处理后试样的屈服强度,分别约为1010,980和855 MPa。在SRB接种的溶液中,双级时效处理、单级时效和调质处理试样的屈服强度,分别约为950,970和850 MPa,分别比无菌溶液降低了5.9%,1%和0.58%。实验结果表明,双级时效处理后的17-4 PH不锈钢对SRB最敏感,经过调质处理工艺试样的SRB敏感性降低。

图3

图3

经不同工艺热处理的17-4 PH不锈钢试样在不同环境中的应力-应变曲线及断面收缩率

Fig.3

Stress-strain curves of samples A (a), B (b) and C (c) in different conditions and their reductions of area (d)

图3d为17-4 PH不锈钢在不同环境介质中的断面收缩率。可知,单级时效、双级时效和调质处理试样均在空气中拥有最大的断面收缩率。与空气中相比,施加的恒定应变可以降低试样的断面收缩率。与无菌溶液相比,SRB接种溶液中单级时效、双级时效和调质处理试样的断面收缩率分别减少了5.38%, 7.74%和3.72%。

式中,A0为试样的原始横截面积,mm2;A1为断裂后试样的横截面积,mm2。

式中,ψs为在3.5%NaCl溶液中测得的断面收缩率,%;ψa为在空气中测得的断面收缩率,%。

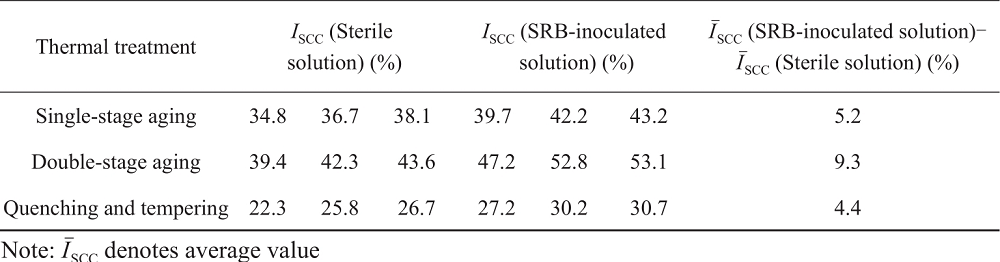

由上面两式可知,当ISCC的值越接近1时,SCC的敏感性越高。表2显示了在无菌和SRB接种溶液中17-4PH不锈钢的ISCC值。可见,在有菌环境下,单级时效、双级时效和调质处理试样的ISCC分别提高了5.2%,9.3%和4.4%。

表2 不同热处理后的试样在无菌和SRB接种溶液中的ISCC值

Table 2

|

2.2.2 断口形貌分析

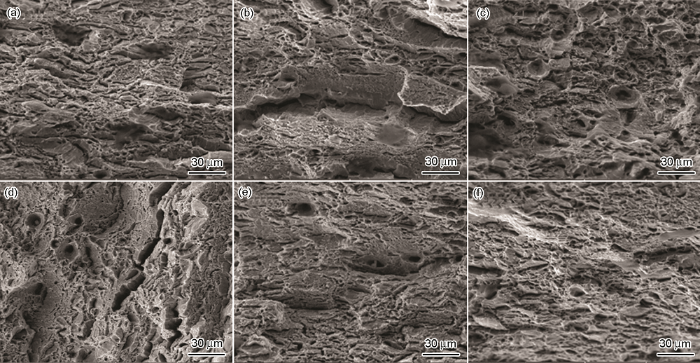

图4

图4

经不同工艺热处理的17-4 PH不锈钢在不同环境中的断口形貌

Fig.4

Fracture morphologies of 17-4 PH stainless steel samples with heat treatments of single-stage aging (a, d), double-stage aging (b, e) and quenching and tempering (c, f) in sterile solution (a~c) and SRB-inoculated solution (d~f)

图5

图5

经不同工艺热处理的17-4 PH不锈钢试样在SRB接种溶液中的侧面断裂形貌

Fig.5

Lateral fracture morphologies of 17-4 PH stainless steel samples with different thermal treatments in SRB-inoculated solution: (a) single-stage aging, (b) double-stage aging, (c) quenching and tempering

3 结论

(1) 热处理工艺可以提高17-4 PH不锈钢的抗腐蚀性能,试样的耐电化学腐蚀能力表现为:调质处理试样>单级时效处理试样>双级时效处理试样。

(2) 在施加应力的单独作用下,双级时效试样中的回火马氏体尺寸粗大,促进裂纹萌生,降低了试样的屈服轻度,增加了应力腐蚀敏感性。

(3) 在SRB接种溶液中,FeS和H2S的产生增强了阳极溶解和氢渗透,加速了腐蚀反应。与无菌溶液相比,阻抗值降低,ISCC增加。双级时效试样的ISCC变化量最大,对SRB最敏感。

参考文献

A nanoscale mechanism of hydrogen embrittlement in metals

[J].The embrittlement of metallic systems by hydrogen is a widespread phenomenon but the precise role of hydrogen in this process is not well understood and predictive mechanisms are not available. Here, a new model is proposed wherein hydrogen accumulation around a microcrack tip prevents crack-tip dislocation emission or absorption, and thus suppresses crack-tip blunting and ductile fracture while promoting cleavage fracture. The conceptual model is demonstrated via atomistic simulations of the evolution of equilibrium hydrogen distributions around a crack tip in Ni under increasing applied load, followed by measurement of dislocation emission and/or cleavage. These analyses are performed in single crystal Ni and for several tilt grain boundaries and several initial crack notch radii, using molecular statics and embedded-atom-method interatomic potentials. A kinetic analysis is used to calculate the size of the "nanohydride" formed at the crack tip as a function of hydrogen chemical potential, temperature, H diffusion rate, load level, and loading rate. Combining the kinetic analysis with the deformation/fracture analysis generates a mechanism map that predicts a ductile-to-brittle transition as a function of material and loading parameters. The mechanism map is applied to predict H embrittlement of unnotched tensile specimens of Ni, and the predictions and experiments match well for material parameter values expected to be pertinent in these materials. The mechanism proposed and validated here directly identifies the role of H in driving a change in fracture mode and toughness as a function of material and loading parameters. (C) 2010 Acta Materialia Inc. Published by Elsevier Ltd.

A synergistic D-tyrosine and tetrakis hydroxymethyl phosphonium sulfate biocide combination for the mitigation of an SRB biofilm

[J].Microbiologically influenced corrosion (MIC) is a major problem in various industries such as oil and gas, and water utilities. Billions of dollars are lost to microbiologically influenced corrosion (MIC) each year in the US. The key to MIC control is biofilm mitigation. Sulfate-reducing bacteria (SRB) are often the culprits. They are also involved in souring and biofouling. SRB biofilms are notoriously difficult to eradicate. Due to environmental concerns and increasing costs, better biocide treatment strategies are desired. Recent studies suggested that D-tyrosine and some other D-amino acids may signal biofilm dispersal. Experimental results in this work indicated that D-tyrosine is an effective biocide enhancer for tetrakis hydroxymethyl phosphonium sulfate (THPS) that is a green biocide. Desulfovibrio vulgaris (ATCC 7757) was used in biofilm prevention and biofilm removal tests. It was found that 100 ppm D-tyrosine alone and 50 ppm THPS alone were both ineffective against the SRB biofilm. However, when 1 ppm D-tyrosine was combined with 50 ppm THPS, the synergy between the two chemicals successfully prevented the establishment of the SRB biofilm on C1018 mild steel coupon surfaces in batch treatment tests. It also eradicated established SRB biofilms from coupon surfaces in both 1 and 3-h shock treatment tests.

Effect of sulfate-reducing bacteria on the pitting corrosion behavior of 18-8 stainless steel

[J].2).]]>

硫酸盐还原菌对18-8不锈钢点蚀行为的影响

[J].2).]]>

Effects of sulphate-reducing bacteria on crevice corrosion in X70 pipeline steel under disbonded coatings

[J].

Effect of cathodic polarization and sulfate reducing bacteria on mechanical properties of different steels in synthetic sea water

[J].

Influence of bacteria on film formation inhibiting corrosion

[J].

Carbon source starvation triggered more aggressive corrosion against carbon steel by the Desulfovibrio vulgaris biofilm

[J].

Electron mediators accelerate the microbiologically influenced corrosion of 304 stainless steel by the desulfovibrio vulgaris biofilm

[J].

Mechanistic modeling of biocorrosion caused by biofilms of sulfate reducing bacteria and acid producing bacteria

[J].

Effect of heat treatment on corrosion resistance of 05Cr17Ni4Cu4Nb steel

[J].

热处理对05Cr17Ni4Cu4Nb钢耐蚀性的影响

[J].

Synergistic effects of a sulfate-reducing bacteria and an applied stress on the corrosion behavior of 17-4 PH stainless steel after different heat treatments

[J].

Heat treatment and tensile properties of martensitic stainless steel

[J].

马氏体不锈钢热处理及其拉伸性能

[J].

Microstructure of welded joints of x5CrNiCuNb16-4 (17-4 PH) martensitic stainlees steel after heat treatment

[J].

Influence of heat treatment on microstructure and properties of 17-4PH martensitic stainless steel

[J].

热处理对17-4PH马氏体不锈钢显微组织及性能的影响

[J].

Hydrogen induced plasticity in stress corrosion cracking of engineering systems

[J].

Effect of cathodic potentials on the SCC behavior of E690 steel in simulated seawater

[J].

Effect of electrochemical potential and solution concentration on the SCC behaviour of X-70 pipeline steel in NaHCO3

[J].

Effects of corrosion product deposit on the subsequent cathodic and anodic reactions of X-70 steel in near-neutral pH solution

[J].

Stress corrosion cracking behavior of X80 pipeline steel in acid soil environment with SRB

[J].

SRB-biofilm influence in active corrosion sites formed at the steel-electrolyte interface when exposed to artificial seawater conditions

[J].

Critical review: Microbially influenced corrosion of buried carbon steel pipes

[J].

The influence of an oxide layer on hydrogen permeation through steel

[J].

In situ characterization by localized electrochemical impedance spectroscopy of the electrochemical activity of microscopic inclusions in an X100 steel

[J].