目前,常用的微合金化技术是在钢中添加一定量的耐蚀性元素,如Cu、Cr、Ni等。研究表明,Cu能够在锈层中形成氧化物,从而提高锈层的致密性。同时,Cu能够与其他合金元素发生协同作用,进而达到提高钢的耐大气腐蚀性能的效果[16~18]。Cr是一种很好的耐大气腐蚀元素,它能够促进腐蚀产物稳定化,同时其尖晶石结构化合物富集在腐蚀产物层内侧能够抵挡Cl-的入侵,能够有效提高钢的耐大气腐蚀性能[19~22]。Ni是优良的耐腐蚀元素,它能够引起钢腐蚀电位的正移,增强钢基体的耐蚀性,同时促进腐蚀产物转变[22~25]。然而,当前的研究仍然集中在这些主要合金元素上,对于微量合金元素(如Nb、Sn、Sb、Ca等)与高强钢的耐蚀性之间的内在关联的认识还不够全面。

研究表明,Sb具有提高钢铁耐蚀性的作用,特别是在酸性环境中。例如,鞍钢等钢铁企业发现,含Sb低合金钢可以作为耐酸钢板应用于运输含硫化物的煤矿的车辆机械。近期的研究则表明,除了耐酸性环境以外,Sb也能够增加钢在海洋大气中的耐蚀性。杨颖等[26]通过为期一个月的室内周浸模拟实验,研究了模拟污染海洋大气环境中Sb与Sn对钢耐蚀性的影响。结果表明,Sb和Sn都可以降低钢的腐蚀速率,并且都能够产生稳定的难溶于酸的氧化物,提高锈层保护性,从而提高了钢的耐蚀性。Wu等[27]在南海环境下开展了为期一年的室外暴露实验,证明了在钢中添加Sb有利于抑制电化学反应,并且随着时间的增加,含Sb钢的腐蚀速率明显降低。同时,Sb的添加改善了腐蚀产物膜的物理结构。Yang等[28]研究了含Sb钢在黄海大气环境中形成的锈层及其对耐蚀性的益处,表明加入Sb后,钢的锈层更加致密,能够阻止Cl-进入基体,从而降低其腐蚀速率。然而,当前多数研究都是通过室内模拟实验或者室外短期暴露实验来探究Sb微合金化对钢铁材料耐蚀性的影响,而关于Sb对较长周期下钢铁材料耐蚀性的影响研究相对较少。除此之外,不同的服役环境也会对钢的腐蚀行为产生不同的影响。目前的研究环境大多在实验室模拟环境或热带和暖温带海洋大气环境下,但是对于亚热带海洋大气区的研究较少。因此,有必要开展亚热带海洋大气环境下Sb对高强结构钢腐蚀行为的影响机制的研究。

本文采用电化学测量、现场暴露实验和各种表征方法研究亚热带海洋大气中含Sb钢和无Sb钢的腐蚀行为。通过电化学技术获取了两种钢的动电位极化曲线,采用扫描电子显微镜(SEM)分析钢表面腐蚀产物的形貌和横截面元素分布,利用X射线衍射(XRD)和X射线光电子能谱(XPS)分析钢表面的腐蚀产物物相组成,通过激光共聚焦显微镜(LSCM)统计分析表面腐蚀坑尺寸演变规律。相关研究结果有助于提升钢铁材料耐蚀性,促进新型耐蚀钢开发,具有十分重要的意义。

1 实验方法

1.1 材料制备

本实验设计制备了含Sb和不含Sb的两种高强结构钢,其化学成分列于表1。首先通过真空熔炼制备成圆形钢锭,在1200 ℃下保温2 h均匀化,然后在1000 ℃下冷却2 h,以促进沉淀相的形成,保证材料的强度和韧性。随后热轧3道次,轧制完成后,在水中淬火至420~440 ℃,最后在空气中冷却至室温。

表1 实验钢的化学成分 (mass fraction / %)

Table 1

| Material | C | Si | Mn | P | S | Cr | Cu | Ni | Sb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Sb-free | 0.058 | 0.27 | 1.56 | 0.007 | 0.003 | 0.45 | 0.32 | 0.82 | - | Bal. |

| Sb-added | 0.053 | 0.25 | 1.58 | 0.010 | 0.002 | 0.44 | 0.35 | 0.84 | 0.012 | Bal. |

1.2 电化学测试

电化学测试在CS300M电化学工作站上进行,采用传统的三电极系统,其中铂片为对电极(CE),饱和甘汞电极(SCE)为参比电极(RE),钢试样为工作电极(WE)。从钢板上切下10 mm × 10 mm × 3 mm的块状样品,焊接导线后用环氧树脂密封保留1 cm2的工作区域。外露表面用SiC砂纸打磨,然后用去离子水和无水乙醇清洗,晾干待用。电化学测试溶液为3.5% (质量分数) NaCl。首先测量开路电位(OCP)约30 min保证系统达到稳定状态。然后,测量在-0.5~0.4 V (vs. SCE)电位范围内的动电位极化曲线,扫描速率为0.5 mV/s。所有测试均在室温(约25 ℃)下进行,至少测量3次,以确保重复性。

1.3 室外暴露实验

室外暴露实验地点位于上海市临港新片区东海大桥附近,距东海约2000 m。该地区气候条件属典型的亚热带季风性气候。年平均气温为17.9 ℃,年平均湿度为74.2%,年降雨量超过1100 mm,室外暴露周期约2 a。实验前,从钢板上切割100 mm × 75 mm × 4 mm的样品,用240#至800#的SiC砂纸打磨试样各表面,然后用去离子水和无水乙醇进行清洗并将其吹干,随后进行称重并编号。每种样品包含4块,其中3块用于腐蚀速率分析,1块用于腐蚀形貌与成分分析。

1.4 腐蚀速率测量

实验完成后,取回样品。通过除锈液(500 mL HCl + 500 mL H2O + 3.5g C6H12N4)在超声波清洗机中进行超声除锈,随后,用去离子水和无水乙醇进行清洗并吹干,称重并利用

式中,CR为腐蚀速率,μm/a;ω0 和ωt 为腐蚀前与腐蚀后去掉腐蚀产物的质量,g;S为试样表面积,m2;ρ为密度,7.8 g/cm3;t为暴露时间,h。

1.5 腐蚀产物分析

从被取回的样品上切取合适尺寸的块状样品,使用JSM-7800F场发射扫描电子显微镜(SEM)、EPMA-8050G电子探针(EPMA)和Keyence VK X250型激光共聚焦显微镜(LSCM)观察腐蚀产物与试样表面形貌,并分析腐蚀产物元素组成。在Smartlab SE设备上采用具有Co靶的XRD分析腐蚀产物的物相组成,扫描速率为6°/min,扫描范围为10°~80°。利用AXIS SUPRA+型X射线光电子能谱仪(XPS)研究腐蚀产物层中Sb的存在形式,结合能位置通过C标准结合能(284.8 eV)进行校准。

2 结果与讨论

2.1 微观结构

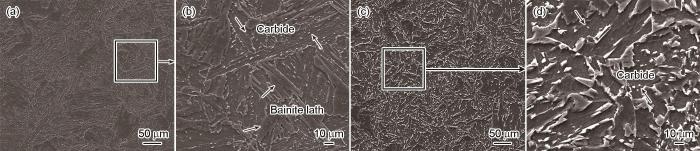

图1

图1

无Sb钢和含Sb钢的显微组织结构

Fig.1

Microstructures of Sb-free steel (a, b) and Sb-added steel (c, d)

2.2 极化曲线

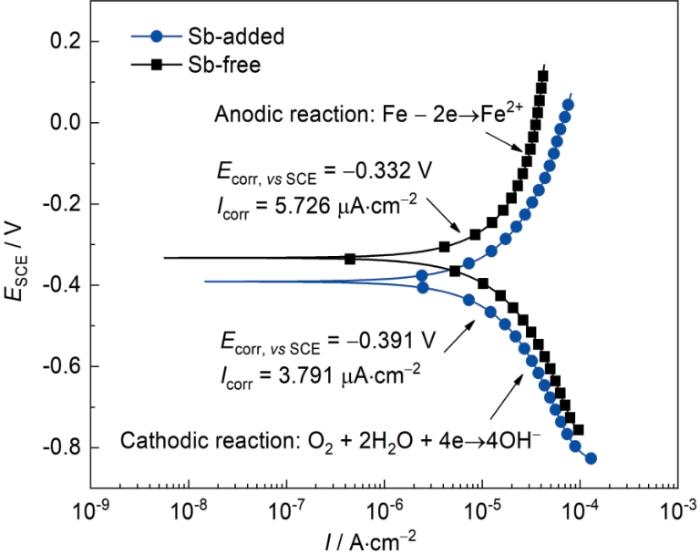

图2

图2

含Sb钢和无Sb钢的动电位极化曲线

Fig.2

Potentiodynamic polarization curves of Sb-free and Sb-added steels

2.3 腐蚀速率

经过室外暴露实验后,两种钢的腐蚀速率经过

式中,R为相对腐蚀速率;CR和C

2.4 腐蚀产物分析

2.4.1 表面腐蚀产物形貌与组成

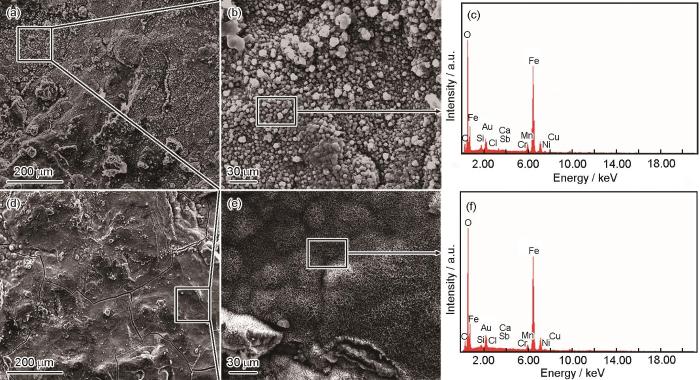

图3

图3

暴露试验后样品表面腐蚀产物形貌和成分

Fig.3

Surface morphologies and EDS analysis results of Sb-free steel (a-c) and Sb-added steel (d-f) after atmospheric exposure experiment

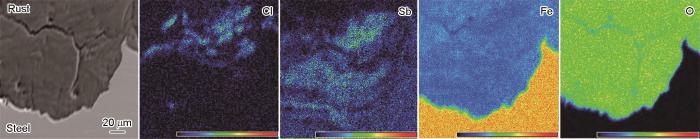

2.4.2 横截面产物形貌和EPMA分析

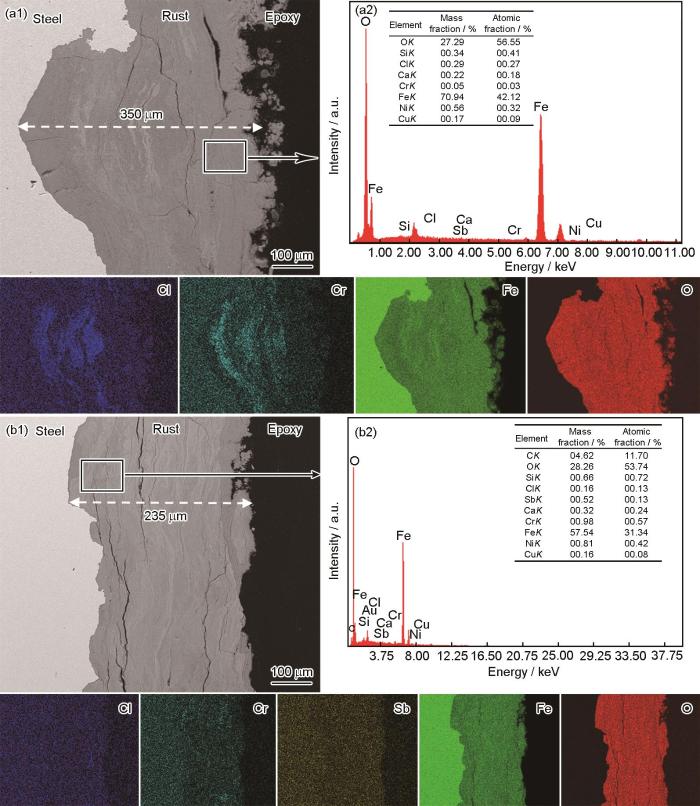

图4

图4

腐蚀产物层的截面形貌和元素分布

Fig.4

Cross-sectional morphologies (a1, b1) and element distributions (a2, b2) of the corrosion product films formed on Sb-free steel (a) and Sb-added steel (b) during atmospheric exposure

图5

图5

含Sb钢横截面局部腐蚀产物层EPMA分析

Fig.5

EPMA analysis of the local areas of the corrosion product films formed on Sb-added steel during atmospheric exposure

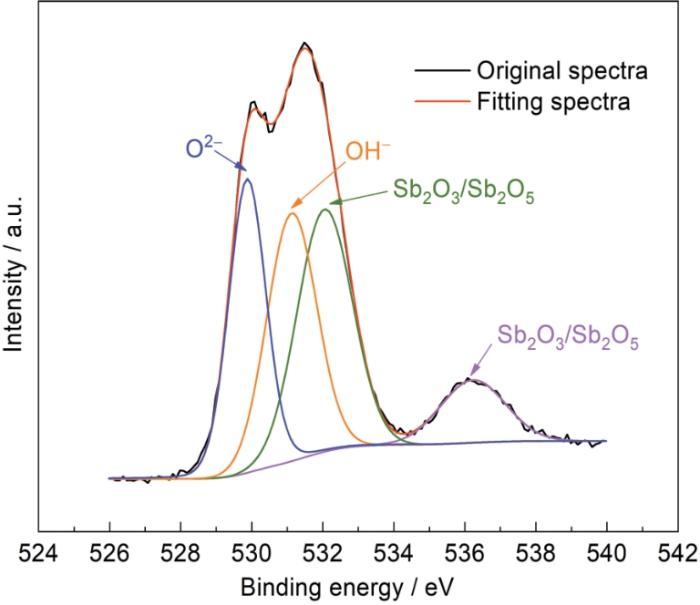

2.4.3 XRD和XPS分析

通过XRD分析了两种钢腐蚀产物的相组成,结果如图6所示。两种钢的腐蚀产物基本相同,主要由α-FeOOH,γ-FeOOH,Fe3O4和γ-Fe2O3 4种结晶相组成,它们是海洋大气中高强结构钢腐蚀产物的常见成分[37,38]。图6b中使用了RIR方法进行半定量分析以确定相比例,由图可见,无Sb钢的腐蚀产物中γ-FeOOH所占比例为70.86%,α-FeOOH所占比例为5.10%。因为Fe3O4和γ-Fe2O3很难用XRD区分,所以给出了Fe3O4/γ-Fe2O3总的含量,为24.04%。添加Sb后的γ-FeOOH所占比例减少至61.56%,α-FeOOH的含量增加,比例为8.70%,Fe3O4/γ-Fe2O3比例增加至29.73%,说明Sb的添加能够促进γ-FeOOH向Fe3O4和α-FeOOH的转化[26]。图6b中还计算了腐蚀产物层保护系数,即α/γ*[39]。其中,α表示腐蚀产物层中α-FeOOH的比例,γ*表示腐蚀产物层中γ-FeOOH和其他产物的比例之和。该值越高,说明腐蚀产物层中稳定产物越多,腐蚀产物层越致密,保护性越强。由图可见,与无Sb钢相比,含Sb钢的α/γ*值明显更大,表明腐蚀产物层的保护作用增强,进而能够减缓钢的腐蚀,降低腐蚀速率,提高耐蚀性。

图6

图6

两种钢大气暴露后表面腐蚀产物的XRD分析及α/γ*比例

Fig.6

XRD analysis of the corrosion products formed on two steels during atmospheric exposure (a), and α/γ* ratios (b)

图7

图7

含Sb钢腐蚀产物中Sb元素的XPS谱

Fig.7

XPS fine spectrum of Sb 3d in the corrosion products of Sb-added steel

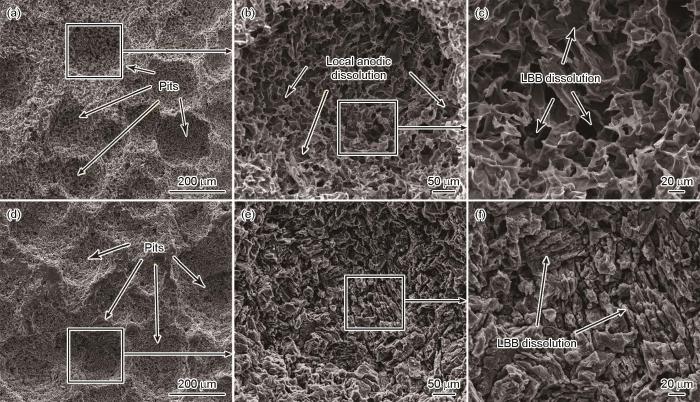

2.4.4 腐蚀形貌

图8为去除腐蚀产物后无Sb钢和含Sb钢的表面形貌。从图中可以看出钢表面有不同程度的损伤,表面出现了很多大大小小的腐蚀坑,这些凹坑通常与腐蚀产物层下方强烈的阳极溶解过程有关[27,35]。对于无Sb钢,凹坑的深度和宽度较大,且表面较为粗糙,如图8a所示。添加Sb后,凹坑的深度明显减小,如图8d所示。从图8c和f中可以看到腐蚀坑底部沿LBBs表现出典型的优先溶解特性,这一现象表明腐蚀过程中存在明显的不均匀性。无Sb钢的溶解相对更加明显,如图8c所示。LBB溶解是由于LBB的高电化学活性和坑底部Cl-聚集导致的局部酸化[40]。相比于无Sb钢,含Sb钢的溶解过程相对较弱,这些结果表明Sb的添加能够削弱腐蚀产物层下局部阳极溶解过程。

图8

图8

去除腐蚀产物后2种钢样品表面形貌

Fig.8

Surface morphologies of Sb-free steel (a-c) and Sb-added steel (d-f) after atmospheric exposure and then removal of corrosion products

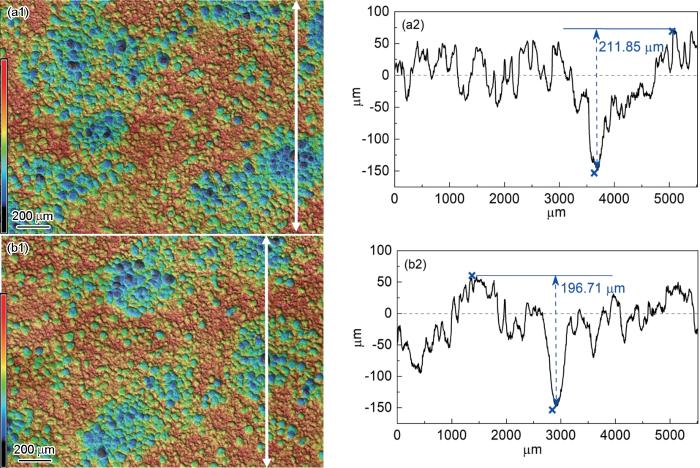

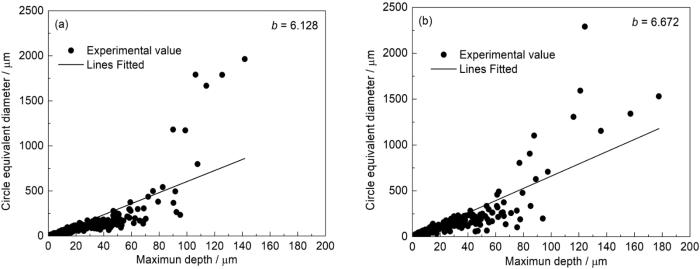

为了准确获取去除腐蚀产物后的表面轮廓与凹坑尺寸,利用LSCM对腐蚀后钢材表面的三维腐蚀形貌进行分析。从图9中可以看出,无Sb钢和含Sb钢表面都呈现出不均匀的全面腐蚀过程,但含Sb钢不均匀腐蚀的区域占比较小,并且腐蚀坑深度较浅,这说明Sb的添加能够抑制钢的不均匀腐蚀过程。从图9中的最大腐蚀坑深度也能够看出Sb的添加显著降低了腐蚀坑深度。为了更好的分析腐蚀坑的特征,对腐蚀坑的深度和等效直径进行了统计分析并进行拟合,结果如图10所示,随着Sb的加入,拟合直线的斜率b是增大的,这种变化表明腐蚀坑在直径方向上变大,在深度方向上变浅。这一统计结果可以证实,添加Sb能够改善钢的局部腐蚀特征,使其朝着均匀腐蚀方向发展,这一统计结果也与图8和9所示的形貌相一致。

图9

图9

去除腐蚀产物后2种钢样品的表面三维轮廓和最大凹坑深度

Fig.9

3D surface profiles (a1, b1) and maximal pit depths (a2, b2) of Sb-free steel (a) and Sb-added steel (b) after the removal of corrosion products

图10

图10

2种钢样品表面腐蚀坑的统计分析

Fig.10

Statistical analysis of corrosion pits of Sb-free steel (a) and Sb-added steel (b)

3 结论

(1) 含Sb钢比无Sb钢在亚热带海洋大气环境中更耐腐蚀。在东海环境暴露2 a后,Sb添加使高强结构钢的腐蚀速率降低了18.97%,这归因于其对腐蚀产物膜保护性的提升和对膜下局部腐蚀过程的抑制。

(2) Sb添加有利于钢表面形成更加致密的腐蚀产物层,能够促进γ-FeOOH向Fe3O4和α-FeOOH的转化,同时能够产生化学性质稳定的Sb2O3/Sb2O5,有利于腐蚀产物层阻挡侵蚀性离子进入内锈层,从而对钢基体具有良好的保护作用。

(3) Sb的添加能够缓解腐蚀产物膜下的局部阳极溶解过程,抑制腐蚀坑的生长,使得腐蚀坑朝着宽度方向发展,即促进了高强结构钢表面形貌特征由不均匀腐蚀向均匀腐蚀转变。

参考文献

Experiment research on microstructure and mechanical properties of high strength low alloy structural steels

[J].

高强度低合金结构钢组织性能试验研究

[J].

Study on welding technology of Q690D low alloy high strength structural steel

[J].

Q690D低合金高强结构钢焊接工艺研究

[J].

Initial corrosion behavior of carbon steel and high strength steel in South China Sea atmosphere

[J].

碳钢和高强钢在南海大气环境中的初期腐蚀行为研究

[J].

Early corrosion behavior of EH36 ship plate steel in tropical marine atmosphere

[J].

热带海洋大气环境中EH36船板钢早期腐蚀行为研究

[J].在高湿、高热、高盐度和强辐照的湛江海洋大气腐蚀试验站对EH36船板钢进行了15、30、90、180和360 d的暴露实验。通过腐蚀失重计算了不同暴露周期的腐蚀速率,采用SEM观察了锈层表面和截面的微观形貌,采用X射线衍射仪分析了锈层的组成成分,采用EDS分析了锈层中的元素分布,同时对暴露后的试样进行了极化曲线测试。结果表明:EH36船板钢的腐蚀速率先增大、后减小;暴露360 d后,Cr、Ni和Si扩散到锈层中,分布较为均匀,提高了钢的耐腐蚀性能;暴露180和360 d的锈层中均含有γ-FeOOH、β-FeOOH、Fe<sub>3</sub>O<sub>4</sub>和α-FeOOH,暴露360 d的锈层中α-FeOOH较多,β-FeOOH较少,锈层中α/γ=0.615,尚未形成稳定的保护性锈层。

Corrosion behavior of S420 steel in different marine zones

[J].

S420海工钢在不同海洋区带环境下的腐蚀行为研究

[J].

Corrosion behavior of X65 pipeline steel: comparison of wet-dry cycle and full immersion

[J].

Corrosion and pitting of 6060 series aluminium after 2 years exposure in seawater splash, tidal and immersion zones

[J].

Effect on marine immersion corrosion of carbon content of low alloy steels

[J].

Stress corrosion cracking mechanism of Nb/Sb-microalloyed high strength steels in polluted marine atmosphere

[D].

铌和锑微合金化高强钢在污染海洋大气中的应力腐蚀机理研究

[D].

Effect of micro-alloying with Cr, N and Al on corrosion resistance of high manganese austenitic steel in acidic salt spray environment

[J].

微合金化对高锰奥氏体钢在酸性盐雾环境下的耐蚀性能影响研究

[J].

Effect of Ag micro-alloying on microstructure and corrosion behavior of Mg-Zn-Ca alloy

[J].

Ag微合金化对Mg-Zn-Ca合金微观组织及腐蚀行为的影响

[J].

Review on niobium application in microalloyed steel

[J].

Kinetics and microstructural change of low-carbon bainite due to vanadium microalloying

[J].

Effects of Cu microalloying on corrosion behavior of spring steel 54SiCr6

[J].

Corrosion of Cu-doped Ni-Mo low-alloy steel in a severe marine environment

[J].

A study of the evolution of rust on Mo-Cu-bearing fire-resistant steel submitted to simulated atmospheric corrosion

[J].

Synergy of Cu and Sb to enhance the resistance of 3%Ni weathering steel to marine atmospheric corrosion

[J].

A new understanding of the effect of Cr on the corrosion resistance evolution of weathering steel based on big data technology

[J].In this work, we studied the effect of Cr element on the corrosion resistance evolution of weathering steel based on corrosion big data technology. It suggested that corrosion big data technology is suitable for evaluation of the effect of microalloying Cr element on the corrosion evolution behavior of weathering steel. New understandings prove that the effect of Cr on the corrosion process is dynamic rather than static, the processes is affected by both of the environmental factors and the electrochemical or chemical reactions in the rust layer. Besides, Cr element has both beneficial effect and detrimental effect on the corrosion resistance of weathering steel. The beneficial effect is that the general corrosion resistance of Cr-additional steel is better than that of Cr-free steel, while the detrimental effect is that localized corrosion is intensified as the increase of Cr content in the Cr-additional steel.

The Influence of 1wt.%Cr on the corrosion resistance of low-alloy steel in marine environments

[J].

Effects of Cr content on corrosion behaviour and corrosion products of spring steels

[J].

Microstructure and corrosion resistance of hot rolled Cr/Ni micro-alloying high strength weathering steel

[J].

热轧态Cr、Ni微合金化高强度耐候钢组织与耐蚀性能

[J].

Optimizing the resistance of Cr-advanced steel to CO2 corrosion with the addition of Ni

[J].

Effects of Ni addition on mechanical properties and corrosion behaviors of coarse-grained WC-10(Co, Ni) cemented carbides

[J].

Effect of Ni on the corrosion resistance of bridge steel in a simulated hot and humid coastal-industrial atmosphere

[J].

Effect of Sb and Sn on the corrosion behavior of low alloy steel in simulated polluted marine atmosphere

[J].

Sb和Sn微合金化对低合金钢在模拟污染海洋大气中腐蚀行为的影响

[J].

Roles of Sb addition on the corrosion resistance of the low‐alloy steel in a real tropical marine atmosphere

[J].

A study of rust layer of low alloy structural steel containing 0.1%Sb in atmospheric environment of the Yellow Sea in China

[J].

Atmospheric corrosion behavior of Nb- and Sb-added weathering steels exposed to the South China Sea

[J].

Effect of bainitic microstructure on the susceptibility of pipeline steels to hydrogen induced cracking

[J].

Effect of ausforming on microstructure and hardness characteristics of bainitic steel

[J].Effects of process parameters of the ausforming such as temperature, strain and strain rate on the martensitic start temperature, kinetics of isothermal bainitic transformation and microstructure refinement of a low carbon carbide-free bainitic steel were investigated. It was found that applying plastic deformation to untransformed austenite during intermediate temperatures decreased the martensite start temperature of steel and enabled isothermal bainitic transformation at low temperatures. Hereby, ausforming significantly generated heterogeneous nucleation sites, which accelerated the overall kinetics of bainitic transformation and thus increased bainitic phase fraction in steel. In addition, the ausforming enhanced the stability of austenite that led to reduced amount of martensite after cooling down to room temperature. Finally, the ausforming parameters and observed microstructure features were correlated and discussed along with the hardness of steel. (C) 2020 The Authors. Published by Elsevier B.V.

Electrochemical corrosion, hydrogen permeation and stress corrosion cracking behavior of E690 steel in thiosulfate-containing artificial seawater

[J].

Effect of Nb on corrosion behavior of simulated weld HAZs of X80 pipeline steel in simulated seawater environments corresponding to shallow sea and deep sea

[J].

Nb对X80钢焊接热影响区在模拟海水中腐蚀行为的影响

[J].通过对两种Nb含量的X80钢进行热处理来模拟出包含 (ICHAZ)、细晶区 (FGHAZ) 和粗晶区 (CGHAZ) 的热影响区组织。通过金相显微镜观察热模拟组织的形貌,通过透射电镜 (TEM) 来观察热影响区析出相的分布状况。两种Nb含量的X80钢与所模拟出来的组织相互比较,分析它们在浅海与深海的电化学行为以及在浅海中的短期腐蚀行为,从而明确Nb对X80钢及其模拟组织在浅海与深海中腐蚀行为影响。结果表明,焊接热影响区中粗晶区及两相热影响区的腐蚀速率最大,并且Nb能够提高X80钢的均匀性及腐蚀产物膜的致密性,从而提高其耐蚀性。此外,在深海中NbC纳米析出相能够充当氢陷阱,捕集一定量的氢,从而提高其在深海中的耐蚀性。

Effect of Ca and Sb on the corrosion resistance of E690 steel in marine atmosphere environment

[J].

Field corrosion study of 690MPa grade Sb-containing high strength bridge steel in tropical oceanic environment

[J].

Integral effects of Ca and Sb on the corrosion resistance for the high strength low alloy steel in the tropical marine environment

[J].

Corrosion behavior of the low alloy weathering steels coupled with stainless steel in simulated open atmosphere

[J].

Weathering steels: From empirical development to scientific design. A review

[J].

Corrosion evolution and stress corrosion cracking behavior of a low carbon bainite steel in the marine environments: Effect of the marine zones

[J].

Corrosion and SCC initiation behavior of low-alloy high-strength steels microalloyed with Nb and Sb in a simulated polluted marine atmosphere

[J].