深海环境的极端条件,如高静水压力、低温、强腐蚀性等,是对海洋工程材料耐腐蚀性能的严峻挑战。吉帕级海工钢以其高强度、高韧性、良好的耐腐蚀性能,成为支撑深海油气开采、海底矿产资源勘探、深海空间站建设等重大工程的关键材料。然而,深海环境中的高静水压力是一个重要的环境因素,它可能对吉帕级海工钢及其焊缝的腐蚀行为产生显著影响。因此,需要深入研究这些影响,以便更准确地评估吉帕级海工钢及其焊缝的耐腐蚀性能和使用寿命。

目前,已有较多关于静水压力对多种材料的腐蚀行为影响的研究,如贾红刚[1]研究表明在常压下,15.5 MPa海水环境中Al-Zn-In-Mg-Ti牺牲阳极的电化学容量及电流效率均有所降低。孙海静[2]研究表明静水压力主要通过加速阴极氧还原过程加速了Al-Zn-In-Mg-Ti合金的腐蚀,静水压力的升高使Al-Zn-In-Mg-Ti牺牲阳极消耗率增大,输出电量降低,阳极质量损耗明显增大,放电效率下降。王金龙[3]研究表明15 MPa的静水压力下Q235钢腐蚀失重增加了48%,自腐蚀电位和阳极反应变化不大,阴极反应速度加快。贾红刚[1]认为静水压力的增大未改变低碳钢的腐蚀机理,却一定程度上抑制了阴极过程和阳极过程,从而导致腐蚀速率逐渐降低。Yang等[4,5]研究了静水压力对X70钢点蚀行为的影响,结果表明静水压力可以增加亚稳态点蚀萌生的频率,加速点蚀的形成和生长。Beccaria等[6~14]研究了静水压力对Al及其合金、AISI 300和400不锈钢点蚀的影响,结果表明静水压力可通过改变腐蚀产物的组成及致密性影响材料的点蚀性能。腐蚀产物性质的改变既可能促进、也可能抑制材料的耐蚀性。郑家青[15]研究表明提高循环静水压力促进了2Cr13钢的阳极过程而对阴极过程影响微弱,而对0Crl8Ni9和00Crl7Nil4Mo2钢的阴、阳极过程均有促进作用。相较于常压条件,在高静水压力下形成的钝化膜较薄且更不稳定。文献[16~18]从多角度分别研究了静水压力对316L不锈钢钝化及点蚀行为的影响。Zhang等[19]认为静水压力提高了Fe-20Cr合金发生亚稳态点蚀的频率和向稳态点蚀发展的倾向。Yang等[20,21]研究表明静水压力对Ni-Cr-Mo-V高强钢亚稳态点蚀的生长有促进作用,静水压力促使10Ni5CrMoV钢的腐蚀形貌由局部腐蚀特征向均匀腐蚀特征转变。由此可见,静水压力对不同材料的腐蚀行为有着不同的影响机制。

焊接是海工钢制造和使用过程中必不可少的工艺,焊接接头处不可避免受到热循环的影响,出现晶粒粗大、组织偏析、化学成分不均匀等不良现象[22,23]。研究[24]表明,A710焊接接头的母材、热影响区和焊缝的组织不一致,导致各区域的耐蚀性存在差异。焊缝区组织存在板条马氏体,其耐蚀性最差,其次是热影响区和母材。研究[25]表明,母材电位较负,焊缝区电位较正。由于微观组织不均匀,熔合区和热影响区中的电位分布不均匀,熔合区中的粒状贝氏体电极电位高于针状铁素体,热影响区的针状铁素体电位高于块状铁素体,因此,这些微区电位的差异会导致在腐蚀环境中形成微小原电池,促使这些区域发生腐蚀。对X70管线钢焊接接头各区域耐蚀性的研究表明,焊缝的耐蚀性最优,热影响区耐蚀性次之,近热基体耐蚀性最差[26,27]。然而,另一项研究[28]表明,X56钢焊接接头在海水中焊缝部位的腐蚀速率大于母材与热影响区。焊接接头中热影响区作为阴极被保护,焊缝和母材作为阳极优先腐蚀。在浅海和深海(1000 m)环境中,X65钢焊接接头在浅海环境下的腐蚀速率大于深海环境下的腐蚀速率,浅海环境以点蚀为主,深海环境只在熔合线附近腐蚀相对较快,焊缝区腐蚀不明显;热影响区(HAZ)的腐蚀电位均低于焊缝和母材区,导致焊缝区域存在电偶效应,加速了HAZ的腐蚀[29]。由此可见,在不同实验体系中,焊接接头的腐蚀机制影响因素较为复杂,所呈现的腐蚀规律有所不同。因此,作为一种新研发的高强海工钢,阐明吉帕级海工钢及其焊缝在静水压力作用下的腐蚀行为及机制是十分必要的。

鉴于此,本文以一种吉帕级海工钢母材及其焊缝金属为研究对象,采用线性极化电阻(LPR)、电化学阻抗谱(EIS)、动电位极化及电化学噪声方法(EN)研究了不同静水压力(0.1、6及12 MPa)对该材料在3.5% (质量分数) NaCl溶液中腐蚀行为的影响,并讨论了相应的影响规律和机制,期望能够为吉帕级海工钢焊接接头的腐蚀防护提供理论依据和技术支持,进而延长海工构筑物的使用寿命,降低维护成本,对工业生产和实际应用具有重要意义。

1 实验方法

实验材料为焊接吉帕级海工钢板,分别按母材及焊缝区域,用线切割将其分别切割成大小为10 mm × 10 mm × 3 mm的试样。进行电化学测试前用环氧树脂冷镶嵌,保留工作面大小为10 mm × 10 mm。将工作面用砂纸逐级打磨至2000号,置于干燥器中备用。

利用实验室搭建的模拟深海腐蚀电化学测试系统[30]进行常压和高压下电化学测试,用低温恒温循环水槽控制高压釜内温度为(25 ± 0.2) ℃,实验所用电化学工作站为Gamry Reference 600 Plus,工作电极为海工钢试样,辅助电极为纯Pt片,参比电极为实验室自制的Ag/AgCl/3.5%NaCl参比电极 (本文用Ag/AgCl表示,常压下其电极电位相对于饱和甘汞电极为5 mV)。

将试样置于静水压力分别为0.1、6和12 MPa的3.5%NaCl中进行开路电位(OCP)、EIS和动电位极化测试。线性极化时设定扫描速率为0.166 mV/s,扫描范围为±20 mV vs OCP。EIS测试时,设定扫描频率范围为105~10-2 Hz,扰动幅值为10 mV。动电位极化测试时,设定扫描速率为0.5 mV/s。

在0.1及12 MPa的3.5%NaCl溶液中分别进行电化学噪声测试。工作电极和对电极为等面积的吉帕级海工钢试样,参比电极为Ag/AgCl电极,采用ESA 410软件采集电化学噪声信号,测量模式为ZRA模式,采样频率为5 Hz。使用MathWorks Matlab 2018b软件编写代码对实验数据进行处理分析。在基于散粒噪声理论的随机极值分析时,采用DWT去除直流漂移,选择小波函数为“db4”,分解层数为8层。

使用SiC砂纸将吉帕级海工钢母材及焊缝金属逐级打磨至2000#,然后使用金刚石抛光膏进行抛光,最后用4%HNO3-酒精溶液刻蚀3 s。用FEI XL-30FEG型扫描电镜(SEM)分别观察吉帕级海工钢母材及焊接接头区域的金相组织特征。将实验后的金属试样依次清洗、烘干,采用SEM观察样品表面腐蚀形貌。

2 结果与讨论

2.1 吉帕级海工钢母材及焊缝的金相组织

图1为吉帕级海工钢母材及焊缝的金相组织SEM照片。由图可见,吉帕级海工钢母材由板条贝氏体组织构成,分布较为均匀,无明显晶界。吉帕级海工钢焊缝金属的金相组织同样由板条贝氏体组织构成,但分布较不均匀,且贝氏体组织有所增大。

图1

图1

吉帕级海工钢母材及焊缝的金相组织SEM照片

Fig.1

Metallographic structure of the base metal (a) and welded beam (b) of GPa-grade offshore engineering steel

2.2 吉帕级海工钢母材及焊缝的腐蚀形貌

图2为吉帕级海工钢母材及焊缝在0.1和12 MPa 3.5%NaCl溶液中腐蚀后表面SEM形貌。可以看出,0.1 MPa下,母材表面主要发生均匀腐蚀,当压力升高到12 MPa后,表面除了均匀腐蚀形貌,还呈现出局部区域腐蚀倾向增大的趋势。对于焊缝金属,在0.1 MPa下,表面腐蚀呈现均匀腐蚀以及局部腐蚀坑,当静水压力增大至12 MPa后,局部腐蚀坑更为明显。这说明,静水压力对母材及焊缝金属的局部腐蚀都有促进作用。相较于母材,焊缝金属的局部腐蚀倾向更为明显,这可能与图1所示组织差异有关。焊缝金属板条贝氏体组织更为粗大且不均匀,更易形成微电偶腐蚀[25],导致局部腐蚀倾向增大。而静水压力对不同金属或组织的电位差异具有放大效应[31],这意味着微电偶腐蚀在静水压力的作用下会进一步增大,从而导致高静水压力下焊缝金属的局部腐蚀倾向进一步增强。

图2

图2

吉帕级海工钢母材及焊缝在0.1和12 MPa 3.5%NaCl溶液中腐蚀后表面形貌

Fig.2

Surface morphologies of GPa-grade offshore engineering steel base metal (a, b) and welded beam (c, d) after corrosion in 0.1 MPa (a, c) and 12 MPa (b, d) 3.5%NaCl solution

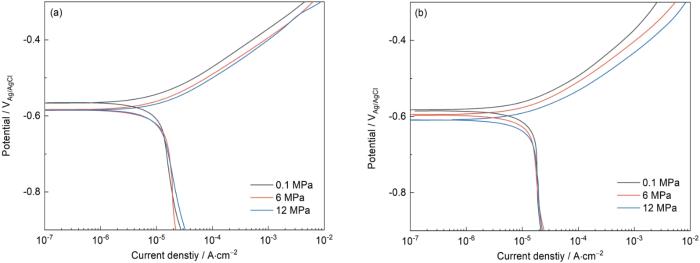

2.3 吉帕级海工钢母材及焊缝的极化曲线

图3

图3

吉帕级海工钢母材及焊缝在不同静水压力下的极化曲线

Fig.3

Polarization curves of the base metal (a) and welded beam (b) of GPa-grade offshore engineering steel under different hydrostatic pressures

表1 根据极化曲线拟合所得Ecorr及Icorr参数

Table 1

| Materials | Pressure / MPa | Ecorr / V | Icorr / μA·cm-2 |

|---|---|---|---|

| Matrix | 0.1 | -0.533 | 3.154 |

| 6 | -0.589 | 3.851 | |

| 12 | -0.592 | 5.503 | |

| Welded | 0.1 | -0.586 | 3.275 |

| 6 | -0.594 | 5.978 | |

| 12 | -0.612 | 6.575 |

2.4 吉帕级海工钢母材及焊缝的线性极化电阻及EIS

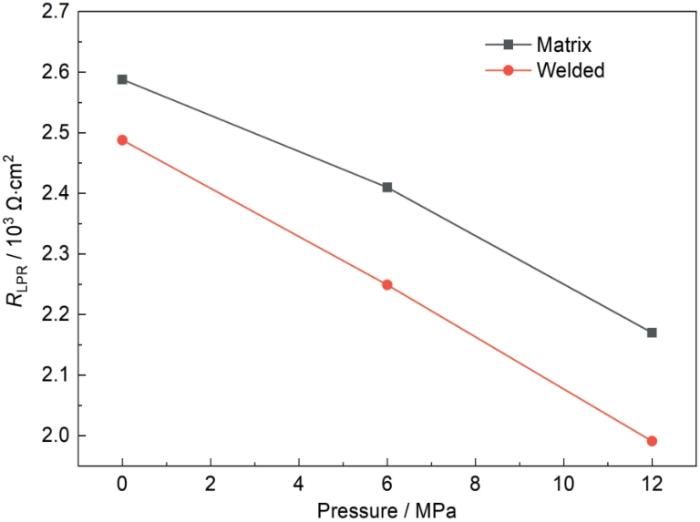

图4所示为吉帕级海工钢母材及其焊缝金属在静水压力分别为0.1、6和12 MPa的3.5%NaCl中的线性极化电阻(RLPR)图。一般情况下,RLPR值的大小反映出材料的腐蚀快慢。由图可见,提高静水压力,吉帕级海工钢母材及焊缝金属的RLPR均减小,静水压力增大提高其腐蚀速率。在不同静水压力条件下,母材的RLPR均大于焊缝金属,这表明母材比焊缝具有更高的耐蚀性。

图4

图4

吉帕级海工钢母材及焊缝在不同静水压力下的RLPR

Fig.4

RLPR values of the base metal and welded beam of GPa-grade offshore engineering steel under different hydrostatic pressures

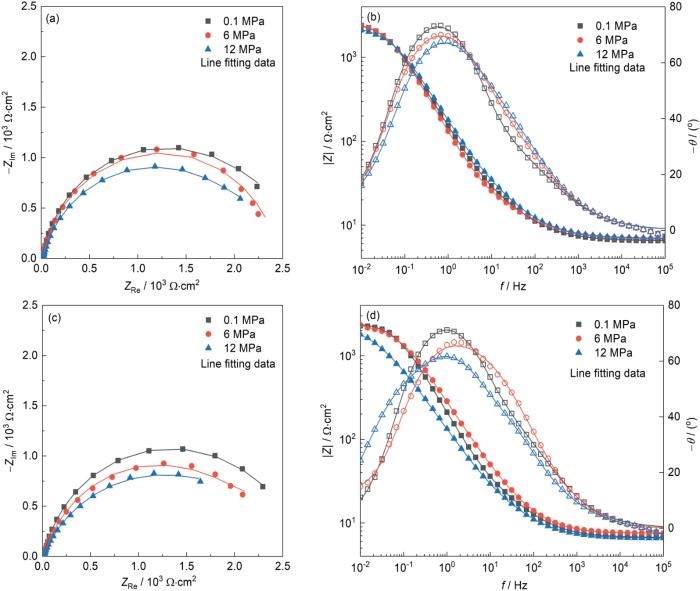

图5所示分别为吉帕级海工钢母材及其焊缝金属在静水压力分别为0.1、6和12 MPa的3.5%NaCl中的EIS图。由图可见,母材及焊缝金属的阻抗都呈现容抗特征,圆弧半径的大小可表示阻抗值的大小,反应出材料的耐蚀性能的高低。提高静水压力,母材及焊缝金属的阻抗圆弧半径均降低,说明静水压力升高降低了材料的耐蚀性。在不同静水压力条件下,母材的阻抗圆弧半径均大于焊缝金属,这表明在不同静水压力条件下,母材的耐蚀性能均优于焊缝金属。在中低频区,随静水压力升高,母材及焊缝金属的相位角均逐渐降低。此外,在相同静水压力条件下,与母材相比,焊缝金属的相位角也有所降低。一般情况下,在低频及中低频区,电极过程与物质的扩散过程密切相关,电化学过程往往受到扩散控制的影响。图3所示极化曲线结果显示,海工钢母材及焊缝金属的阴极去极化过程均受氧的极限扩散控制,阳极发生钢的活性溶解反应。当相位角增大时,可能意味着扩散控制的减弱。这是因为相位角的增大通常与电荷传递阻抗的减小相关联,而电荷传递阻抗的减小可能是由于电极反应动力学速率的加快或扩散路径的改善。这意味着,提高静水压力可能导致电极过程中电荷传递阻抗的减小。

图5

图5

吉帕级海工钢母材及焊缝在不同静水压力下的EIS图

Fig.5

Nyquist (a, c) and Bode (b, d) plots of the base metal (a, b) and welded beam (c, d) of GPa-grade offshore engineering steel under different static hydrostatic pressures

图6

表2 根据电化学阻抗拟合所得参数

Table 2

| Material | Pressure | Rs | Qo, Y | Qo, n | Ro | Wo | Qa, Y | Qa, n | Ra |

|---|---|---|---|---|---|---|---|---|---|

| MPa | Ω·cm2 | mS·s n ·cm2 | - | Ω·cm2 | mS·s0.5·cm2 | mS·s n ·cm2 | - | Ω·cm2 | |

| Matrix | 0.1 | 6.44 | 1.35 × 10-3 | 0.875 | 2569 | 3.95 × 10-2 | 4.29 × 10-4 | 0.597 | 17.24 |

| 6 | 6.79 | 1.45 × 10-3 | 0.920 | 2390 | 1.74 × 10-2 | 3.34 × 10-2 | 0.605 | 13.31 | |

| 12 | 6.89 | 1.19 × 10-3 | 0.864 | 2146 | 1.65 × 10-3 | 4.55 × 10-3 | 0.584 | 12.84 | |

| Welded | 0.1 | 6.68 | 9.18 × 10-4 | 0.902 | 2436 | 1.24 × 10-2 | 2.60 × 10-3 | 0.633 | 14.59 |

| 6 | 6.56 | 1.90 × 10-3 | 0.758 | 2237 | 1.88 × 10-2 | 5.01 × 10-3 | 0.632 | 5.525 | |

| 12 | 7.58 | 7.46 × 10-5 | 1.000 | 1991 | 8.45 × 10-3 | 8.55 × 10-4 | 0.856 | 0.687 |

2.5 吉帕级海工钢母材及焊缝的电化学噪声结果

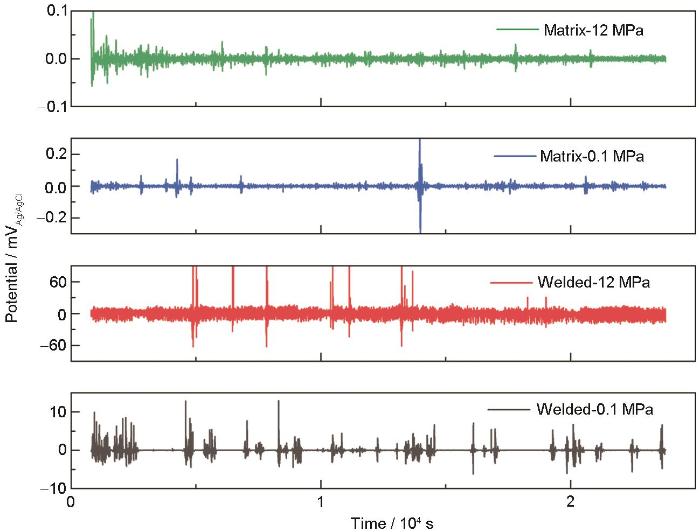

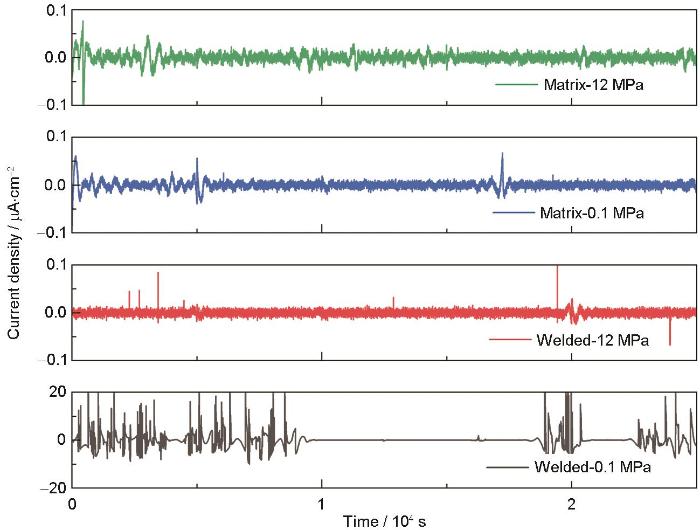

图7

图7

母材及焊缝金属分别在0.1和12 MPa下电化学电位噪声去直流漂移后的噪声图谱

Fig.7

Noise spectra of electrochemical potential after DC drift removal for the base metal and welded beam at 0.1 and 12 MPa, respectively

图8

图8

母材及焊缝金属分别在0.1和12 MPa下电化学电流噪声去直流漂移后的噪声图谱

Fig.8

Noise spectra of electrochemical current after DC drift removal for the base metal and welded at 0.1 and 12 MPa, respectively

图9所示为吉帕级海工钢母材及焊缝金属在静水压力分别为0.1和12 MPa的3.5%NaCl中的qvsfn 图。由图可知,在不同静水压力条件下,焊缝金属比母材具有更大的q值及更小的fn 值,这说明焊缝金属的局部腐蚀倾向更大。对于母材及焊缝金属,提高静水压力均使q值增大fn 值减小,说明提高静水压力导致母材及焊缝金属的局部腐蚀倾向皆增大。

图9

图9

吉帕级海工钢在静水压力分别为0.1和12 MPa的3.5%NaCl中的q vs fn 图

Fig.9

q vs fn plots for GPa-grade offshore engineering steel in 3.5%NaCl at static hydrostatic pressures of 0.1 and 12 MPa

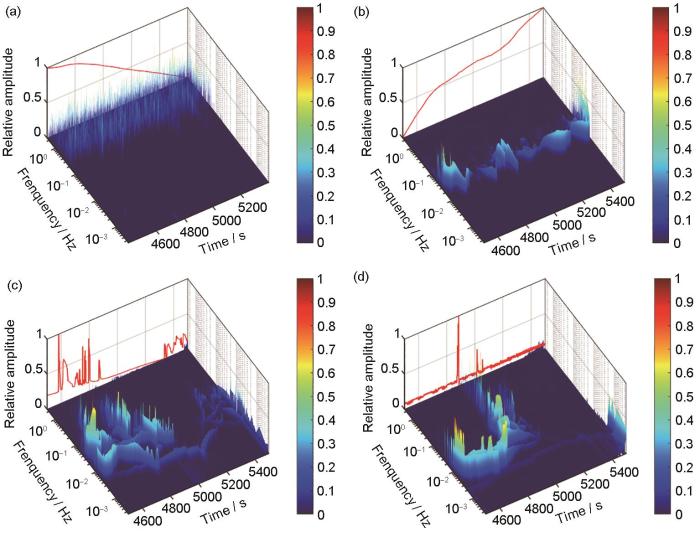

时频分析后的电化学噪声数据可以更详细地表征材料的腐蚀过程。通过区分不同电位和电流噪声信号可以将腐蚀过程细分为有着短时间尺度、高频率的活化控制;有着长时间尺度、低频率的扩散控制和有中时间尺度和中等频率的混合控制。一般来说有着最高相对能量的时间尺度在腐蚀过程中占据主导地位。较短的时间尺度 (高频率) 与相对较快的过程相关,如点蚀形核、亚稳态点蚀、稳态点蚀过程等;较长的时间尺度 (低频率) 与相对较慢的过程相关,如气泡吸脱附、腐蚀产物脱落和扩散过程等。一般认为,点蚀形核过程总是先于其他类型的局部腐蚀,且比腐蚀产物的扩散、脱附等过程快得多[41]。均匀腐蚀以长时间尺度过程为主,而局部腐蚀以短时间尺度过程为主[42~47]。

希尔伯特黄变换 (Hilbert-Huang Transform,HHT) 方法作为一种较为先进的电化学信号时频分析技术被广泛应用。HHT[48]的核心在于经验模态分解 (EMD)。EMD是将噪声信号x(t)分解为N个固有模态函数 (IMF)。x(t)可表示为所有IMF分量及一个残余趋势量rN (t)的总和,即:

对所有的IMF分量逐一进行Hilbert变换:

式中,P为Cauchy主值,形成的解析信号为:

式中i =

忽略

式中,Re代表复数量的实部值。至此,可以得到“幅值an (t)-频率ωn (t)-时间t”的三维分布图,称为Hilbert谱。将幅值an (t)表示为频率和时间为自变量的函数an (ω, t),将其对时间进行积分,如

图10为吉帕级海工钢母材及焊缝金属在静水压力分别为0.1和12 MPa的3.5%NaCl中典型EPN的Hilbert谱,为便于与原始噪声信号比较,将原始噪声信号的振幅归一化后绘制于图的后侧面。图 11为吉帕级海工钢母材及焊缝金属在静水压力分别为0.1和12 MPa的3.5%NaCl中Hilbert边际谱。结合Hilbert谱及边际谱图可见,母材在0.1 MPa下相对振幅主要集中于高频区域,说明其表面主要发生均匀腐蚀;而在12 MPa下,相对振幅主要集中于中低频区域,这表明其局部腐蚀倾向增大。焊缝金属在0.1 MPa下,相对振幅主要分布于中低频区域,同时出现均匀腐蚀及局部腐蚀的情况;而在12 MPa下,相对振幅进一步向低频区域移动,这表明焊缝金属的局部腐蚀倾向进一步增大。

图10

图10

吉帕级海工钢母材及焊缝金属在静水压力分别为0.1和12 MPa的3.5%NaCl中典型EPN的Hilbert谱

Fig.10

Typical Hilbert spectra of electrochemical potential noise (EPN) for the base metal (a, b) and welded beam (c, d) of GPa-grade offshore engineering steel in 3.5%NaCl at static hydrostatic pressures of 0.1 MPa (a, c) and 12 MPa (b, d)

图11

图11

吉帕级海工钢母材及焊缝金属在静水压力分别为0.1和12 MPa的3.5%NaCl中Hilbert边际谱

Fig.11

Hilbert marginal spectra of the base metal (a, b) and welded beam (c, d) of GPa-grade offshore engineering steel in 3.5%NaCl at static hydrostatic pressures of 0.1 MPa (a, c) and 12 MPa (b, d)

3 结论

(1) RLPR及EIS结果显示,在不同静水压力条件下,吉帕级海工钢母材的耐蚀性均优于焊缝金属。

(2) 极化曲线结果表明,静水压力对吉帕级海工钢母材及焊缝金属的阴极过程影响较小,但明显促进其阳极溶解过程,从而加速吉帕级海工钢母材及焊缝金属的腐蚀速率。

(3) 腐蚀表面形貌表征结果显示,提高静水压力使吉帕级海工钢母材及焊缝金属的局部腐蚀倾向均有所增大。

参考文献

Research on property of Zn reference sacrificial electrode and aluminium alloy anodes under deep-sea simulation

[D].

模拟深海环境下锌参比电极与铝合金牺牲阳极性能研究

[D].

Study on the corrosion behavior of low alloy steel and cathodic protection properties of sacrificial anode in deep sea environment

[D].

深海环境下低合金钢的腐蚀行为及其牺牲阳极阴极保护研究

[D].

The manufacture of experiment equipment for simulated deep sea pressure and study on the influence of deep sea pressure on corrosion behaviors of Q235 mild steel and 316L stainless steel

[D].

模拟深海压力实验装置的制备以及压力对Q235碳钢和316L不锈钢腐蚀行为的影响

[D].

Hydrostatic pressure effects on stress corrosion cracking of X70 pipeline steel in a simulated deep-sea environment

[J].

A statistical study on the effect of hydrostatic pressure on metastable pitting corrosion of X70 pipeline steel

[J].

Influence of hydrostatic pressure on pitting of aluminium in sea water

[J].

Effect of hydrostatic pressure on passivating power of corrosion layers formed on 6061 T6 aluminium alloy in sea water

[J].

Influence of hydrostatic pressure and salt concentration on aluminum corrosion in NaCl solutions

[J].

Aluminum corrosion in slightly alkaline sodium sulfate solutions at different hydrostatic pressures

[J].

Effect of hydrostatic pressure on corrosion behaviour of 5086 Al-alloy in sea water

[J].

Effect of some surface treatments on kinetics of aluminium corrosion in NaCl solutions at various hydrostatic pressures

[J].

The effect of hydrostatic pressure on the corrosion of nickel in slightly alkaline solutions containing Cl- ions

[J].

The effect of salt concentration on nickel corrosion behaviour in slightly alkaline solutions at different hydrostatic pressures

[J].

Influence of passive film composition and sea water pressure on resistance to localised corrosion of some stainless steels in sea water

[J].

Research of prosess of pitting corrosion of stainless steels in simulated deep-sea environment

[D].

模拟深海环境下不锈钢点蚀性能研究

[D].

Degradation in pitting resistance of 316L stainless steel under hydrostatic pressure

[J].

Effect of hydrostatic pressure on the pitting corrosion behavior of 316l stainless steel

[J].

Effect of crevice and hydrostatic pressure on the corrosion behaviors of 316L stainless steel

[D].

缝隙和静水压力环境对316L不锈钢腐蚀行为的影响

[D].

A stochastic analysis of the effect of hydrostatic pressure on the pit corrosion of Fe-20Cr alloy

[J].

Effect of hydrostatic pressure on the corrosion behaviour of Ni-Cr-Mo-V high strength steel

[J].

New understanding of the effect of hydrostatic pressure on the corrosion of Ni-Cr-Mo-V high strength steel

[J].

Study on corrosion of X80 pipeline steel welded joint and its mechanism

[D].

X80管线钢焊接接头腐蚀行为及其机理研究

[D].

Study on stress corrosion behavior of welded joints of marine steel in simulated marine environment

[D].

船用钢焊接接头在模拟海洋环境下的应力腐蚀行为研究

[D].

Study on corrosion resistance of offshore platform steel A710 welded joint

[J].

海洋平台用钢A710焊接接头的耐蚀性研究

[J].

Corrosion behavior of welded joint of low alloy high strength steel in 3.5%NaCl solution

[J].

低合金高强钢焊接接头在3.5%NaCl溶液中的腐蚀行为

[J].

Corrosion behaviour research of X70 pipeline steel welded joints for deep sea

[D].

深海用X70管线钢焊接接头耐蚀性研究

[D].

Investigation of corrosion behavior of welded joint of X70 pipeline steel for deep sea

[J].X70 pipeline steel with thick specifications (40.5 mm) for 3500 m deep sea reached the international advanced level in the wall thickness and service depth. Due to the high heat input during the welding process, the corrosion resistance of inside welding and outside welding would vary depending on the microstructure differences. The corrosion resistance of the welded joints of X70 pipeline for deep sea was studied by the immersion test, the weight loss test, the electrochemical test in this work. The components of the passive film were analyzed by XRD and the microstructure was observed by SEM. The results show that the corrosion resistance of the weld metal is the best. The corrosion resistance of the heat affected zone follows. The corrosion resistance of the base metal is the worst. And for the same area, the corrosion resistance of the inside welding is better than that of the outside welding. The formation of dense Fe3O4 passivation film can effectively slow down the progress of the reaction, and the corrosion products of Fe2O3, FeOOH and Fe(OH)3 which are loose in the outer layer, have no protective effect on the matrix. The microstructure of the weld metal with the best corrosion resistance is mostly the intragranular nucleation ferrite and martensite-austenite (M-A) constituent is fine and uniform. The microstructure gradient of the heat affected zone is the largest, the M-A constituent is coarse and the corrosion resistance is inferior to the weld metal. The base metal consists of ferrite and bainite, the bainite is island-like distribution and the corrosion resistance is the worst. Microstructure of the inside welding is more refined, owing to the influence of outside welding thermal cycle, and the volume fraction of M-A constituent in inside welding is higher than that of the outside welding, so the corrosion resistance is better than that of the outside welding.

深海用X70管线钢焊接接头腐蚀行为研究

[J].

Study on corrosion behavior of welded joints of X56 steel in seawater

[J].

X56钢焊接接头在海水中的腐蚀行为研究

[J].

Comparative study on corrosion of X65 pipeline steel welded joint in simulated shallow and deep sea environment

[J].

X65钢焊接接头在模拟浅表海水和深海环境中的腐蚀行为对比

[J].在实验室模拟条件下,采用失重法及电化学等方法并结合腐蚀形貌显微观察,研究了X65钢焊接接头在浅表海水和深海 (1000 m) 环境中的短期腐蚀行为及其机理。结果表明,X65钢焊接接头在浅表海水环境下的腐蚀速率大于深海环境下的腐蚀速率,浅表海水环境以点蚀为主,深海环境只在熔合线附近腐蚀相对较快,焊缝区腐蚀不明显;在模拟浅表海水和深海环境下,热影响区 (HAZ) 的腐蚀电位均低于焊缝和母材区,导致焊缝区域存在电偶效应,加速了HAZ的腐蚀,形成较厚的腐蚀产物膜。

Influence of hydrostatic pressure on corrosion behavior of ultrapure Fe

[J].

静水压力对超纯Fe腐蚀行为的影响

[J].采用失重测试、动电位极化和电化学噪声研究了静水压力对超纯Fe在3.5%NaCl中腐蚀行为的影响。利用离散小波分析方法去除噪声信号的直流漂移,然后进行散粒噪声和随机分析;利用Hilbert-Huang变换对噪声信号进行时频分析;用SEM观察腐蚀试样的表面形貌。失重测试和动电位极化的研究结果表明,增大静水压力提高了超纯Fe在3.5%NaCl中的腐蚀速率。电化学噪声分析结果表明,在整个浸泡期间,增大静水压力促进了点蚀的发展,提高了局部腐蚀的倾向。在浸泡初期,超纯Fe以发生局部腐蚀(如点蚀形核、亚稳态点蚀、点蚀)的模式为主,增大静水压力对点蚀形核过程有一定的抑制作用,降低了点蚀孕育速率,但对亚稳态点蚀和稳态点蚀的发展过程有促进作用,提高了点蚀生长概率;随着浸泡时间的延长,其逐渐转为以均匀腐蚀的模式为主,增大静水压力仍然促进亚稳态点蚀和稳态点蚀的发展,提高点蚀生长概率,但是却相对地抑制了均匀腐蚀过程。

Influence of hydrostatic pressure on the thermodynamics and kinetics of metal corrosion

[J].In recent years, researches on deep sea corrosion have attracted much attention of many researchers. The high hydrostatic pressure is a distinctive feature of deep-sea environment. The hydrostatic pressure affects the corrosive behavior of metallic materials by modifying the composition, structure and compactness of corrosion products, changing the polarization processes of cathode electrode and anode electrode, altering pitting nucleation rate and growth rate, impacting on chemical reaction rate and equilibrium constant, and varying hydrogen diffusion rate and coverage. However, in essence, the influence of hydrostatic pressure on the corrosion behavior of different metal materials is the manifestation of the thermodynamic and kinetic parameters of the corrosion electrode process caused by hydrostatic pressure. At present, the mechanism of effect of hydrostatic pressure on the thermodynamics and kinetics of corroding electrode processes is unclear yet. In addition, the concerns about the effects of hydrostatic pressure on the chemical properties of materials and seawater are comparatively low. Based on thermodynamics and kinetics, the effects of hydrostatic pressure on the activities of electrode material and ions in environment, including on the solubility, fugacity or activity of gases in environment are analyzed. The influence of hydrostatic pressure on pH value and chemical equilibrium is also discussed. The relationships between hydrostatic pressure and equilibrium electrode potential, as well as the exchange current density, are analyzed. The theoretical model of the effect of hydrostatic pressure on the corrosion behavior of active metals is established. The studies have shown that hydrostatic pressure would increase the activities of materials, ions and dissolved gas in environments, and this is closely related to their partial molar volume. The hydrostatic pressure would magnify the difference in the activity of heterogeneous materials. The larger the partial molar volume difference of the heterogeneous materials, the more obvious the difference in activity. Increasing hydrostatic pressure reduces the equilibrium electrode potential of iron and aluminum anode dissolution reaction while reducing its exchange current density. Increasing hydrostatic pressure increases the equilibrium electrode potential of oxygen reaction and decreases its exchange current density. Increasing hydrostatic pressure reduces the equilibrium electrode potential of hydrogen evolution reaction and increases its exchange current density.

静水压力对金属腐蚀热力学及动力学的影响

[J].以热力学和动力学为基础,分析了静水压力对电极反应中材料的活度、环境中离子的活度、气体的溶解度、活度或逸度的影响,讨论了静水压力对海水环境中的pH值及化学平衡的作用,给出了静水压力与电极反应平衡电极电位和交换电流密度的关系式,并建立了静水压力影响活性金属腐蚀行为的理论模型。研究表明,静水压力可提高材料、环境中离子及溶解气体的活度,且这与其偏摩尔体积密切相关;静水压力对异相材料的活度差异具有放大效应,异相材料的偏摩尔体积相差越大,活度的差异越明显。升高静水压力可降低金属Fe和Al阳极溶解反应的平衡电极电位,同时降低其交换电流密度;升高静水压力可提高吸氧反应的平衡电极电位,降低其交换电流密度;升高静水压力可降低析氢反应的平衡电极电位,增大其交换电流密度。

Effect of surface damage induced by cavitation erosion on pitting and passive behaviors of 304L stainless steel

[J].

Effect of sulphate and molybdate ions on pitting corrosion of aluminium by using electrochemical noise analysis

[J].

Effects of sulphate, nitrate and phosphate on pit initiation of pure aluminium in HCl-based solution

[J].

Analysis of electrochemical noise obtained from pure aluminium in neutral chloride and alkaline solutions

[J].

Measures for the detection of localized corrosion with electrochemical noise

[J].

Shot noise and statistical parameters for the estimation of corrosion mechanisms

[J].

A practical evaluation of electrochemical noise parameters as indicators of corrosion type

[J].

Noise resistance and shot noise parameters on the study of IGC of aluminium alloys with different heat treatments

[J].

Research on crevice corrosion behaviour of 5083 and 6061 aluminum alloys

[D].

5083和6061铝合金缝隙腐蚀行为研究

[D].

Electrochemical noise analysis of LY12-T3 in EXCO solution by discrete wavelet transform technique

[J].

Wavelet transform-based analysis for electrochemical noise

[J].

Calculation of noise resistance by use of the discrete wavelets transform

[J].

Application of wavelet entropy in analysis of electrochemical noise for corrosion type identification

[J].

Using wavelets transform in the analysis of electrochemical noise data

[J].

Analysis of pitting corrosion behavior of pure Al in sodium chloride solution with the wavelet technique

[J].

Novel time–frequency characterization of electrochemical noise data in corrosion studies using Hilbert spectra

[J].

The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis

[J].