5383铝合金是在5083铝合金的成分基础上通过降低Fe、Si等杂质的含量,同时添加少量的Zn、Cu和微量的Cr等元素研制而成的新材料。5383铝合金的力学性能比同状态的5083铝合金提高约10%~15%,而塑性、焊接性能、加工性能、成型工艺性能均略优于5083铝合金,因此正在替代5083铝合金应用于船舶结构、航空航天器具以及模具制造等领域[1]。船舶用铝合金在服役过程中不可避免地承受不同程度的应力与载荷。不同的应力作用会对腐蚀产生不同的效果,交变应力和环境共同作用产生腐蚀疲劳,它造成的腐蚀破坏与构件的使用寿命衰减通常比单一应力产生的后果更严重[2]。应力加载速度的不同也会影响合金应力腐蚀的敏感性,加载速度越快,腐蚀越严重[3]。陈文敬[4]研究了7075铝合金在不同应力作用下的应力腐蚀行为发现随着应力增加,7075铝合金阳极电流增加,表明应力促进阳极溶解。点蚀面积变大,同时伴有晶间腐蚀,自腐蚀电位与击穿电位都呈现负移现象。铝合金表面存在致密的钝化膜,能起到保护基体、减缓腐蚀的作用[5~8]。应力会造成钝化膜的损伤破坏,在应力没有使铝合金钝化膜破裂的腐蚀初期,其作用不显著,但是随着承受应力时间的增长,将会大大地促进铝合金腐蚀[9]。应力和腐蚀的联合效应会降低铝合金的力学性能,这种效应在塑性应力作用下比非应力试样更为显著[10]。并且随着腐蚀时间的推移,力学性能的退化程度更高,腐蚀渗透深度的增长也更快[11]。

为了明确恒载荷实验中载荷大小对5383铝合金及其焊接件电化学腐蚀行为的影响,本文采用四点弯曲夹具对5383铝合金及其钨极氩弧焊焊接接头施加不同大小的载荷,研究其在不同载荷作用下的电化学腐蚀及表面钝化特性,结合扫描电子显微镜(SEM)以及能谱(EDS)等表征结果,查明在外载荷作用下的电化学腐蚀规律并探究腐蚀机理。

1 实验方法

本文选用的实验材料为5383铝合金板材(板厚3 mm),采用钨极氩弧焊焊接方法得到焊接件(焊接电流:60~80 A;焊接速率:8~20 cm/min;氩气流量:15~20 L/min),焊丝选用直径为1.2 mm的5183铝合金,实验所需的材料由中国船舶集团七二五研究所海洋腐蚀与防护全国重点实验室提供。5383铝合金与焊丝的化学成分如表1所示。

表1 5383铝合金及5183焊丝的化学成分 (mass fraction / %)

Table 1

| Material | Mg | Si | Fe | Cu | Mn | Zn | Ti | Cr | Zr | Be | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Base metal | 4.00 | 0.25 | 0.25 | 0.20 | 0.70 | 0.15 | 0.15 | 0.15 | 0.25 | - | Bal. |

| Filler metal | 4.30 | 0.40 | 0.40 | 0.10 | 0.50 | 0.25 | 0.15 | 0.25 | - | 0.0003 | Bal. |

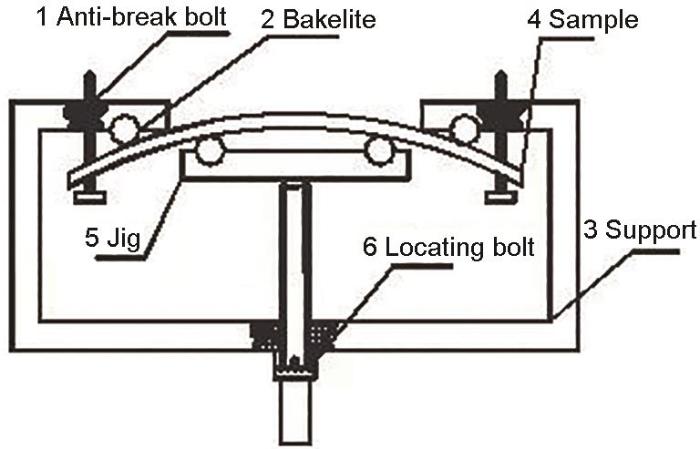

图1

用于恒载荷应力腐蚀过程中电化学测试的样品要垂直于焊缝方向截取,试样尺寸为110 mm × 15 mm × 3 mm。用水磨砂纸逐级打磨试样到外表面光亮、无明显加工痕迹,随后再用丙酮去除表面油渍、酒精清洗并烘干。与应力腐蚀同步进行的电化学测试试样表面的工作面积为1.0 cm2,其余部分全部采用聚四氟乙烯密封。采用ModuLab XM电化学工作站进行电化学测试,测试采用三电极系统,其中参比电极选用封有饱和KCl溶液的218型Ag/AgCl电极,大面积铂片作为对电极,被测样品作为工作电极。电解质溶液为除去泥沙的鳌山湾天然海水,通过恒温水浴锅控制温度在25 ℃左右。首先进行开路测试,待开路电位稳定后,再进行电化学阻抗和极化曲线测试。其中电化学阻抗谱(EIS)测试需要施加幅值10 mV的交流正弦波,测试的频率范围为105~10-2 Hz。动电位极化(LSV)测试的电位扫描范围为-0.5 VSCE~0.5 VSCE,扫描速率为0.166 mV/s。莫特-肖特基(Mott-Socottky)测试的电位扫描范围为-1 VSCE~2 VSCE,固定频率为1 kHz,扫描速率为50 mV/s。每组数据至少重复测试3次获得,以保证数据的可靠性。采用Zeiss ULTRA-55扫描电子显微镜对样品表面的腐蚀形貌进行观察,通过SEM配有的EDS进行元素分析,从而揭示腐蚀产物的化学成分。

2 结果及讨论

2.1 不同载荷下铝合金焊接接头的电化学阻抗

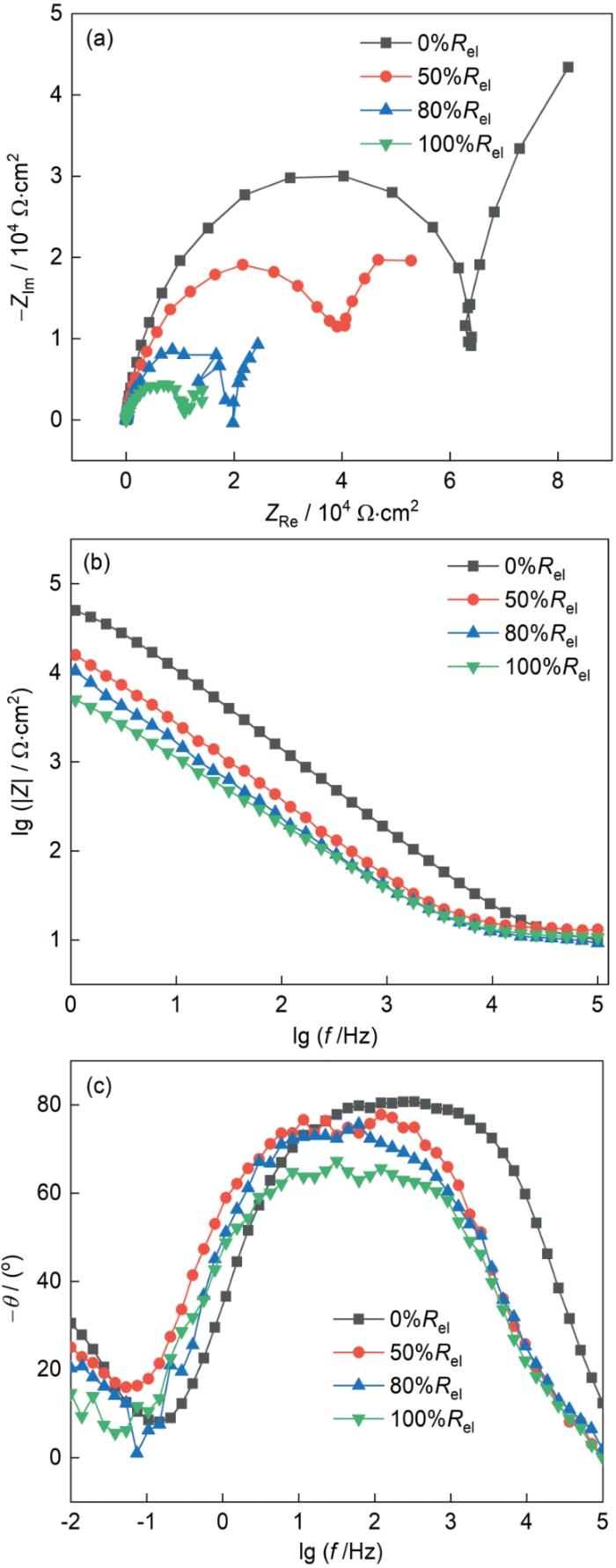

图2为5383铝合金焊接接头在未施加载荷以及在50%Rel,80%Rel、100%Rel载荷作用下测得电化学阻抗谱的Nyquist图和Bode图。由图2a可见,施加不同载荷的电化学阻抗谱形态基本一致,阻抗的容抗弧半径差异明显,随着载荷增大,容抗弧半径依次变小。由图2b可见,施加载荷后模值下降明显,载荷越大,模值下降越明显,这些均表明5383铝合金焊接接头随外加载荷增大腐蚀速率加快。由频率-相角图(图2c)可见,没有施加载荷时,相位角出现接近80°的特征峰,随着载荷增加,特征峰值对应的相位角逐渐减小并向低频移动。在电化学阻抗研究中,特征峰对应为高频区电极电位所引起的金属电极与溶液界面双电层电容充放电的弛豫过程(弛豫过程指双电层电容进行充电或放电时,电极上的电荷与溶液中的离子会经历重新排列和迁移的过程)[13],特征峰向低频区移动意味着试样表面膜变得不稳定甚至破裂。

图2

图2

5383铝合金焊接接头在不同应力下的电化学阻抗谱

Fig.2

Nyquist (a), impedance module (b) and phase angle (c) plots of 5383 aluminum alloy welded joint under different stresses

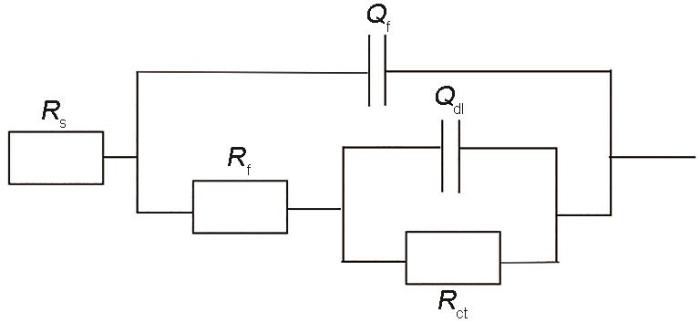

图3

图3

5383铝合金焊接接头在不同载荷下电化学阻抗的等效电路图

Fig.3

Equivalent circuit diagram of EIS measurement for 5383 aluminum alloy welded joint under different applied loads

表2 不同载荷下5383铝合金焊接接头电化学阻抗拟合结果

Table 2

| Applied load / MPa | Rs / Ω·cm2 | Qf / F·cm-2 | nf | Rf / Ω·cm2 | Qdl / F·cm-2 | nct | Rct / Ω·cm2 |

|---|---|---|---|---|---|---|---|

| 0 | 9.688 | 2.024 × 10-6 | 0.9097 | 6.742 × 104 | 2.451 × 10-5 | 1 | 1.429 × 105 |

| 50%Rel | 12.85 | 9.872 × 10-6 | 0.8739 | 4.379 × 104 | 5.689 × 10-5 | 1 | 4.851 × 104 |

| 80%Rel | 10.04 | 1.673 × 10-5 | 0.8510 | 2.183 × 104 | 1.372 × 10-4 | 1 | 2.028 × 104 |

| 100%Rel | 10.26 | 3.438 × 10-5 | 0.7738 | 1.225 × 104 | 4.174 × 10-4 | 1 | 4.511 × 103 |

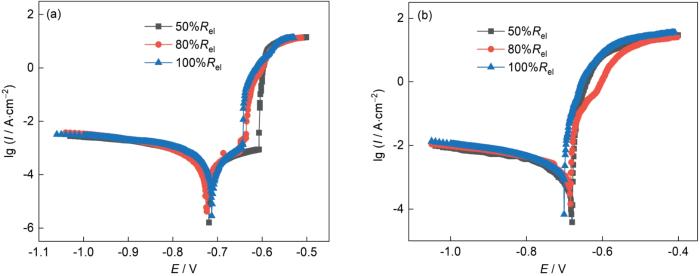

2.2 不同载荷下铝合金及其焊接接头极化曲线测试结果

图4a和b分别是5383铝合金母材与焊接接头在不同应力下的极化曲线。对比两图可见,铝合金母材与焊接接头极化曲线的形态不同,母材有明显的钝化现象,而焊接接头几乎不存在钝化区间。由图4a可见,随着载荷增大钝化区间越来越窄,施加载荷为80%Rel时,在钝化膜被击穿前存在短暂的再钝化状态,而施加载荷为100%Rel,再钝化现象不复存在,这是因为应力的增大使得铝合金表面的钝化膜更容易破裂,也更容易被击穿。5383铝合金母材与焊接接头极化曲线的共同点在于随着外加载荷的增加,自腐蚀电位逐渐负移。这是因为外加载荷使得铝合金在拉应力的作用下发生弹性形变而产生滑移,表面的钝化膜会在滑移的作用下破裂,进而露出新的基体表面,施加外力越大,基体露出新鲜表面的面积越大、溶液渗入基体的速率越快,导致双电层的结构与性质发生了较大的变化,从而表现为自腐蚀电位随着应力的增大而负移。自腐蚀电流的变化主要取决于基体表面裸露的速率[14]。

图4

图4

5383铝合金母材与焊接接头在不同外加载荷下的极化曲线

Fig.4

Polarization curves of the base metal (a) and welded joint (b) of 5383 aluminum alloy under different applied loads

表3为不同外加载荷作用下5383母材与焊接接头极化曲线的拟合结果,可见在不同载荷作用下,焊接接头的自腐蚀电位普遍高于母材的,这是因为焊丝的化学成分与母材不同,焊丝中含有更多的Fe、Cr、Si等元素,它们的电极电位均高于Al的电极电位。母材在施加载荷为80%Rel时,自腐蚀电位达到最负,为-0.72407 V;焊接接头在施加载荷为100%Rel时,自腐蚀电位达到最负,为-0.70102 V。击穿电位为电极表面膜层的破裂电位,击穿电位越正,合金的耐蚀性越好[15~18]。5383母材存在钝化现象,对应有击穿电位。由表3可见,随着载荷增大,母材出现击穿电位负移的现象;施加载荷为100%Rel时,母材的Etp值最负为-0.66440 V,这意味着载荷增加使得表面膜更容易被击穿[19]。

表3 不同载荷作用下5383铝合金母材及焊接接头极化曲线的拟合结果

Table 3

| Applied load / MPa | Ecorr / V | Etp / V | |

|---|---|---|---|

| Base metal | Welded joints | Base metal | |

| 50%Rel | -0.71902 | -0.67978 | -0.60707 |

| 80%Rel | -0.72407 | -0.68400 | -0.63579 |

| 100%Rel | -0.71304 | -0.70102 | -0.66440 |

2.3 5383铝合金表面钝化行为研究

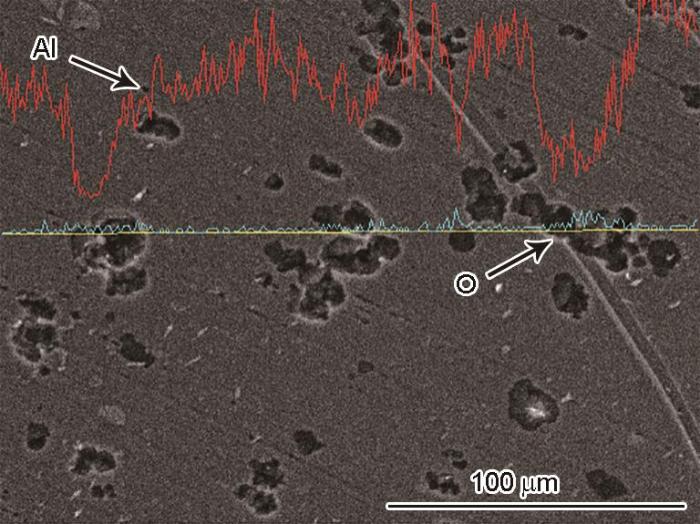

由图4a可见,5383铝合金母材有着明显的钝化现象,铝合金表面形成的钝化膜可以成为铝合金中电子导体相/腐蚀溶液中离子导体相的阻挡层,对电化学反应中电子/离子的传递过程有着阻碍作用。为了明确外加载荷作用下5383铝合金表面钝化膜在极化过程中的变化,采用极化曲线测试和表面形貌表征对铝合金在载荷为50%Rel时的钝化行为展开研究。极化曲线测试先从阴极极化开始,再进行阳极极化。将1号试样的极化曲线测试停止在活化溶解区间,将2号试样测试停止于钝化区间,将3号试样测试停止于点蚀击破电位后电流快速增大区间,4号试样对应一条完整的极化曲线,测试结果分别如图5a~d所示。将经过分段测试极化曲线的试样清洗、冷风吹干后采用SEM观察表面形貌,并采用EDS分析其元素组成。图6为1号试样在极化测试后的表面形貌及EDS分析结果,可见此时1号试样表面没有形成明显的钝化膜,合金表面出现点蚀,这是因为在试样1对应的电位下,尚未达到成膜电位,在以Cl-为主的海水中合金表面容易遭受点蚀,特别在施加载荷为50%Rel时,点蚀坑周围会形成微小裂纹,随着电位的增加点蚀加剧,点蚀坑深度增加。点蚀会引起局部富氢,氢会大大降低铝合金的塑性[20]。通过EDS线扫描分析可知,点蚀坑内的氧元素含量明显高于点蚀坑外,这是由于新露出的基体容易与氧结合形成氧化物。

图5

图5

施加载荷为50%Rel时5383铝合金的分段极化曲线

Fig.5

Staged polarization curves of 5383 aluminum alloy samples under 50%Rel applied load: (a) not entering the passivation zone (Sample 1), (b) not entering the passivation zone (Sample 2), (c) before rapid increase in current after reaching the pitting potential (Sample 3), (d) including the whole zone (Sample 4)

图6

图6

1号试样极化测试后的微观形貌及能谱分析

Fig.6

Surface morphology of Sample 1 after polarization and EDS line scannings of Al and O

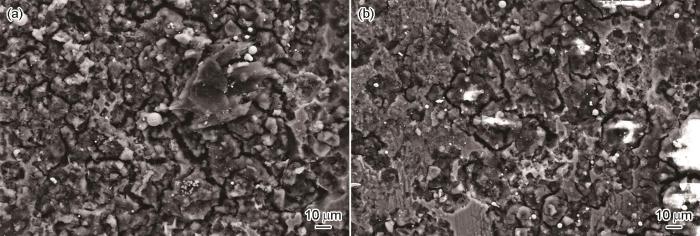

图7为2号试样在分段极化测试后不同区域的微观形貌。可见铝合金表面形成了明显的钝化膜,在应力与极化作用下钝化膜产生了大量裂纹和点蚀坑,这一方面是因为钝化膜表面的缺陷会在外力作用下使得电解质中的Cl-等加速在此处聚集,促进钝化膜发生点蚀;另一方面施加载荷后又会促进滑移带的产生,点蚀坑将作为裂纹源沿着滑移带进行扩展。这两方面因素的共同作用下加剧钝化膜的腐蚀,在2号样品表面形成了纵横分布的裂纹。

图7

图7

2号试样极化测试后的表面形貌

Fig.7

SEM images of two different surface regions (a, b) of Sample 2 after polarization test

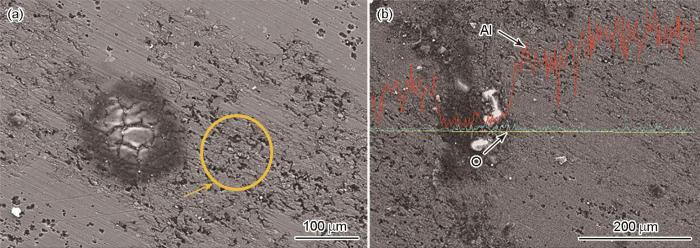

图8

图8

3号试样极化测试后的表面形貌和能谱线扫描分析

Fig.8

Surface morphology of Sample 3 after polarization (a) and EDS line scannings of Al and O (b)

图9

图9

4号试样极化测试后的表面形貌和EDS线扫描分析

Fig.9

Surface morphology of Sample 4 after polarization (a) and EDS line scannings of Al and O (b)

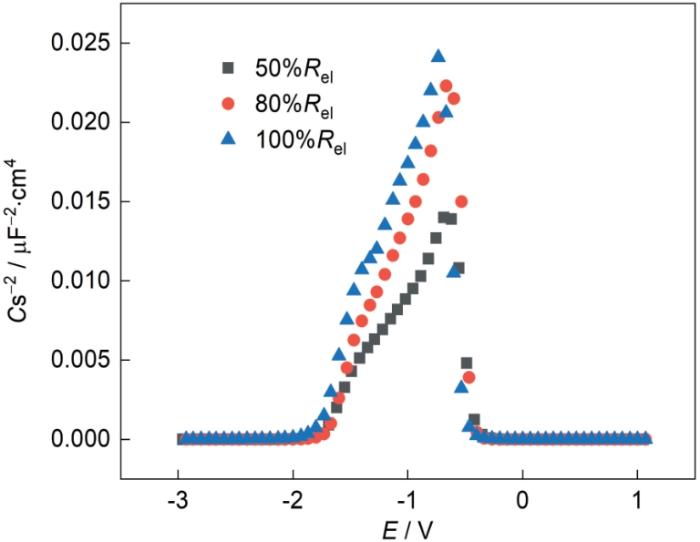

2.4 不同载荷下铝合金Mott-schottky曲线

图10

图10

不同载荷下5383铝合金表面的Mott-schottky曲线

Fig.10

Surface Mott-Schottky curves of 5383 aluminum alloy under different applied loads

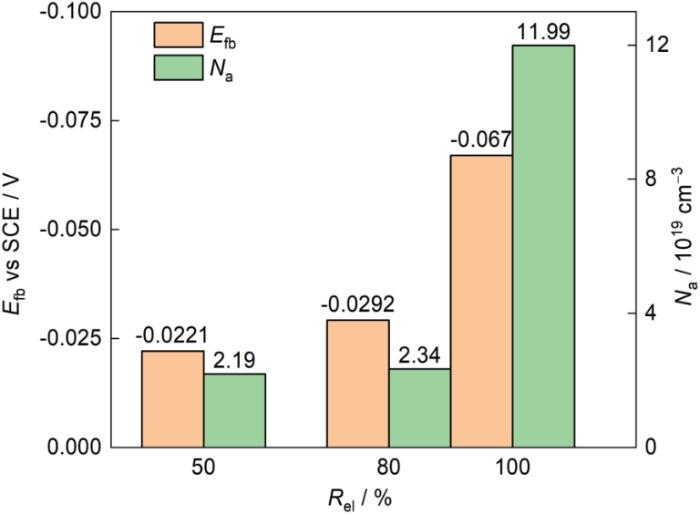

图11是5383铝合金在不同载荷下生成钝化膜的Efb与受主载流子密度Na柱状统计图。由图11可知,施加的载荷从50%Rel增加至80%Rel,铝合金表面的平带电位Efb由-0.0221 V负移到-0.0292 V;载流子密度Na由2.19 × 1019 cm-3增加到2.34 × 1019 cm-3,表现出很小的差距。然而当载荷达到100%Rel时,Efb和Na的变化非常明显,分别达到-0.067 V和1.199 × 1020 cm-3。平带电位Efb是评判钝化膜耐腐蚀性能的重要参数之一,当平带电位Efb变大时,材料表面更容易得到电子,表面形成钝化膜的难度增加。Nd与Na值越大代表钝化膜中的缺陷越多,钝化膜的导电性就会越强,钝化膜越不稳定。载荷从50%Rel分别增加至80%Rel和100%Rel,Efb变大,载流子浓度持续增加,表明钝化膜随外载荷增大变得越来越不稳定。

图11

图11

5383铝合金在不同载荷下形成钝化膜的Efb与Na

Fig.11

Efb and Na values of the passivation films formed on 5383 aluminum alloy under different applied loads

综上可见,5383铝合金本身的耐蚀性比较好,可以生成较为致密的钝化膜。但是在海水环境中、在外载荷作用下钝化膜容易被破坏,载荷越大破坏越严重。海水中的Cl-等腐蚀性离子会在外力引起的裂纹或缺陷处吸附富集加剧铝合金钝化膜的破坏,虽然钝化膜在受到局部损伤和破坏时具有自动修复的能力,然而外力的施加大大破坏了钝化膜的自修复能力。钝化膜的持续破坏使得腐蚀向基体内发展,铝合金在海水中的腐蚀速率增加。

3 结论

(1) 施加载荷为50%Rel、80%Rel、100%Rel会明显降低5383铝合金母材及其焊接接头的耐蚀性,载荷越大耐蚀性越差,母材存在明显的钝化,耐蚀性能优于焊接件。

(2) 50%Rel应力作用下分段极化的测试结果表明随着电极电位的升高,5383铝合金的腐蚀形貌由点蚀变为“裂纹网络”,继续发展成“击穿型”孔洞,这个过程伴随着钝化膜的破损-再生-破损过程,钝化膜被击穿后,铝合金基体会受到严重腐蚀。

(3) 5383铝合金表面的钝化膜具有p型半导体性质,载荷增大使得平带电位Efb逐渐负移、载流子密度Na逐渐增大,表明外加载荷使得铝合金表面钝化膜缺陷增多,保护性能变差。

参考文献

Corrosion behavior of marine 5383 aluminum alloy in simulated seawater

[D].

船用5383铝合金在模拟海水中的腐蚀行为研究

[D].

Corrosion fatigue crack initiation behavior of A7N01S-T5 aluminum alloy welding metal

[J].

A7N01S-T5铝合金焊缝金属腐蚀疲劳裂纹萌生行为

[J].

Study of high-speed-impact-induced conoidal fracture of Ti alloy layer in composite armor plate composed of Ti- and Al-alloy layers

[J].In order to understand the mechanism of conoidal fracture damage caused by a high-speed fragment-simulating projectile in titanium alloy layer of a composite armor plate composed of titanium- and aluminum-alloy layers, the ballistic interaction process was successfully simulated based on the Tuler–Butcher and GISSMO coupling failure model. The simulated conoidal fracture morphology was in good agreement with the three-dimensional industrial-computed-tomography image. Further, three main damage zones (zones I, II, and III) were identified besides the crater area, which are located respectively near the crater area, at the back of the target plate, and directly below the crater area. Under the high-speed-impact conditions, in zone II, cracks began to form at the end of the period of crack formation in zone I, but crack formation in zone III started before the end of crack formation in zone II. Further, the damage mechanism differed for different stress states. The microcracks in zone I were formed both by void connection and shear deformation. In the formation of zone I, the stress triaxiality ranged from −2.0 to −1.0, and the shear failure mechanism played a dominant role. The microcracks in zone II showed the combined features of shear deformation and void connection, and during the formation process, the stress triaxiality was between 0 and 0.5 with a mixed failure mode. Further, the microcracks in zone III showed obvious characteristics of void connection caused by local melting. During the zone III formation, the triaxiality was 1.0–1.9, and the ductile fracture mechanism was dominant, which also reflects the phenomenon of spallation. © 2020 The Authors

Study on the corrosion behavior and electrochemical behavior of high-strength aluminum alloy under stress conditions

[D].

高强铝合金应力条件下的腐蚀行为及其电化学行为研究

[D].

Growth characteristics of stress corrosion cracking in high-strength 7075 aluminum alloy in sodium chloride solutions

[J].

Mitigation effects of over-aging (T73) induced intergranular corrosion on stress corrosion cracking of AA7075 aluminum alloy and behaviors of η phase grain boundary precipitates during the intergranular corrosion formation

[J].

Understanding stress corrosion cracking behavior of 7085-T7651 aluminum alloy in polluted atmosphere

[J].

Stress corrosion behavior of 6082 aluminum alloy

[J].Stress corrosion tests of 6082 aluminum alloy were carried out by using a three-point bending fixture while holding at 50% of yield strength state through different immersion times in 1.5% NaCl electrolyte solution. The electrochemical impedance spectra and dynamic electric potential polarization curves were measured to indicate the stress corrosion behavior of the alloy. Optical microscopy, scanning electron microscopy, and X-ray energy spectrum analysis were applied for microstructural investigations. The results show that all of the Nyquist electrochemical impedance spectra consisted of high- and low-frequency double capacitive arcs. However, an increase in immersion time while holding at 50% of yield stress resulted in a corresponding increase in the corrosion current density, leading to gradual corrosion depth growth, and a decrease in the corrosion resistance of the alloy. 6082 Aluminum alloy included AlMnFeSi, Mg2Si, and Si secondary phases. The different secondary phases presented different stress corrosion behaviors. Stress corrosion cracks were generated at the boundaries of AlMnFeSi and matrix or within the AlMnFeSi phase. Crack direction is always perpendicular to the tensile stress applied. Mg2Si secondary phase was self-corroded as its corrosion potential is lower than that of the matrix. As the electric potential of Si is higher than that of the matrix, corrosion occurred at the matrix side of the boundary between Si and matrix.

Quantitative study of the corrosion evolution and stress corrosion cracking of high strength aluminum alloys in solution and thin electrolyte layer containing Cl-

[J].

Corrosion behavior of 2297 Al-Li alloy under tensile load

[J].

应力作用下2297铝锂合金腐蚀行为研究

[J].

Mechanical properties degradation of aluminum alloys under corrosion environment

[J].

腐蚀环境中铝合金材料力学性能退化研究

[J].

Progress in corrosion behavior of friction stir welded aluminum alloy

[J].

铝合金搅拌摩擦焊接接头腐蚀行为研究进展

[J].

Effect of load on the corrosion behavior of friction stir welded AA7075-T6 aluminum alloy

[J].

Effects of ageing treatment on corrosion behavior of 7075 aluminum alloy coated by micro arc oxidation (MAO)

[J].

Polystyrene/TiO2 nanocomposite coating for strength and toughness enhancement of aluminum alloy 2024-T3 in accelerated stress corrosion cracking

[J].

Stress corrosion behavior of high-strength and high-magnesium aluminum alloys under constant strain conditions in seawater

[D].

船用高强高镁铝合金在模拟海水中恒应变条件下应力腐蚀行为研究

[D].

Reducing stress corrosion cracking susceptibility of high-strength aluminum alloy and its fastener by a novel electromagnetic shocking treatment

[J].

Study on the roles of bisulfite in the stress corrosion cracking of 7050-T7451 aluminum alloy in the thin electrolyte layer environment

[J].

Influence of ultrasonic impact treatment on stress corrosion of 7075 aluminum alloy and its welded joints

[J].

Effect of two-stage ageing on mechanical properties and sensitivity to hydrogen embrittlement of 7050 aluminum alloy

[J].

双级时效对7050铝合金力学性能及氢脆敏感性的影响

[J].以7050铝合金为研究对象,采用双级时效工艺,利用拉伸实验、硬度测试、断面形貌观测研究了7050铝合金的力学性能;采用阴极渗氢法、定氢仪、EDS、SEM等手段研究了双级双峰时效对7050铝合金抗应力腐蚀性能的影响。结果表明:双峰现象存在于7050铝合金双级时效过程中,而延伸率随着时效进行基本呈下降趋势,在峰值位置时有所波动,分别提高3%和5%;随着充氢时间的延长,氢含量呈上升趋势,从相同的充氢时间来看,处在第二时效峰值时氢含量最低,宏观上表现为强韧性好。第二峰强度和硬度的提高是由于增加了一定数量的η'相,塑韧性的增加主要是η'相粒子均匀弥散分布在基体中,导致变形均匀。

Stress corrosion behavior of friction stir welding joint of 7N01 aluminum alloy

[J].

A phase field method for modeling anodic dissolution induced stress corrosion crack propagation

[J].