氢脆会显著影响金属材料的结构性能,降低材料使用寿命,造成巨大安全隐患。因此深入了解阴极保护电位对氢脆的影响对海洋工程有重大的意义。研究表明[6~9],随着充氢电位的负移,材料的氢脆敏感性会逐渐增大。此外,姜秀丹等[10]研究了温度对钢结构氢脆敏感性的影响,表明随着温度升高,材料的氢脆系数增加,氢脆敏感性增大;王贞等[11]在探究应变速率对氢脆敏感性的问题中发现,材料的氢脆敏感性随应变速率的降低而升高,但变化幅度受初始预充氢状态的影响。在温度、应变速率、极化电位对材料氢脆效应的探索中,部分学者认为焊接接头的氢脆效应也不容忽视。这是由于材料进行焊接时,高温作用下氢进入材料内部,增大材料的氢脆敏感性,影响工件的力学性能[5,12~14]。严春妍等[15]在对低合金X90钢焊接接头的实验中发现,焊缝区相比于母材区具有更高的氢脆敏感性;Świerczyńska等[16]对焊接接头试样进行的实验表明,在阴极极化条件下,超级双相不锈钢接头的氢脆敏感性比母材高。但在近期的研究中发现,焊接中热影响区的氢脆敏感性与母材区也有很大差异。Zhang等[17]通过组织不均匀性对X80钢的氢脆敏感性的研究中表明,热影响区的氢脆敏感性明显高于母材;林召强等[18]对高强钢焊缝进行的氢脆敏感性实验中表明热影响区的强度低于母材与焊缝区的强度。综上所述,研究材料氢脆敏感性,不仅要考虑温度、极化电位等外在环境,同时也应考虑焊接所带来的影响。

DH36钢性能优异,已经被普遍应用于海洋结构物的建设领域之中,但由于DH36钢在服役过程中面临氢脆风险,为避免工程中出现较大损失,研究DH36钢焊接构件的氢脆敏感性对保障海洋结构物的安全有重要意义。但现如今对DH36钢的热影响区与焊缝区的氢脆敏感性的研究较少,所以本文将通过氢渗透、金相以及慢应变速率拉伸试验,采用微观宏观表征技术和试验所得力学性能参数等对DH36钢焊接构件的热影响区、焊缝区和母材区进行HE敏感性的研究,为DH36钢在实际海洋工程的使用中奠定基础。

1 实验方法

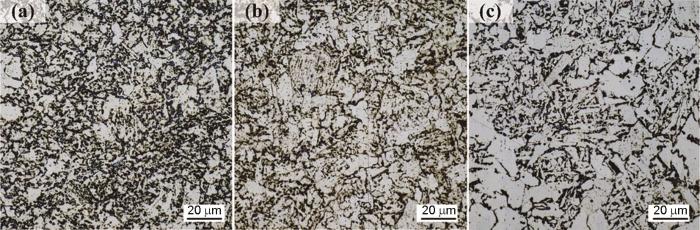

本实验采用通过埋弧焊焊接的DH36钢,埋弧焊使用焊接材料为CHW-S9镀铜低合金高强度钢埋弧焊丝,单面焊,V型坡口,坡口面角度为30°,采用BH-PAW-150型自动焊机进行埋弧焊,焊前将待焊试样在100 ℃下预热30 min,焊接时温度控制在120~200 ℃。DH36钢组成成分(质量分数,%)为:C 0.21,Mn 1.18,Si 0.28,P 0.003,S 0.01,Nb 0.031,V 0.12,Ti 0.011,Ni 0.35,Al 0.041,Fe余量。在焊缝区、热影响区与母材区分别取10 mm × 10 mm × 3 mm的小试片进行逐级打磨至2000#后抛光制成金相试样,用4% (质量分数)硝酸酒精溶液侵蚀15 s后在金相显微镜下观察其显微组织。母材区、热影响区和焊缝区的金相图如图1所示。由图可见,母材与热影响区、焊缝区域皆为铁素体、珠光体组织结构,其中热影响区含有少量贝氏体,焊缝区中的铁素体组织更为粗大。

图1

图1

母材、热影响区及焊缝区金相图

Fig.1

Microstructures of the base metal (a), heat-affected zone (b) and welding metal (c)

图2

图2

试样形状及取样区域示意图

Fig.2

Schematic diagrams of sample shape (a) and sampling areas (b)

采用MFDL-50kN慢拉伸试验机进行拉伸试验,拉伸试验处于恒温25 ℃,应变速率为10-5 s-1,拉伸试验装置图如图3所示。充氢实验采用三电极体系,拉伸试件标距部分为工作电极,采用Ag/AgCl为参比电极,金属Pt为对电极,利用YC-1200A恒电位仪(大连云驰)施加充氢电位,充氢电位分别为0、-850、-950、-1050和-1150 mV。

图3

实验所用溶液为人工海水,主要成分(%)为:NaCl 24.53,MgCl2 5.2,Na2SO4 4.09,CaCl2 1.16,KCl 0.695,NaHCO3 0.201。试件断裂后立即用酒精、去离子水冲洗,冷风吹干后,测量断面收缩率,观察试样宏观与微观断口形貌。

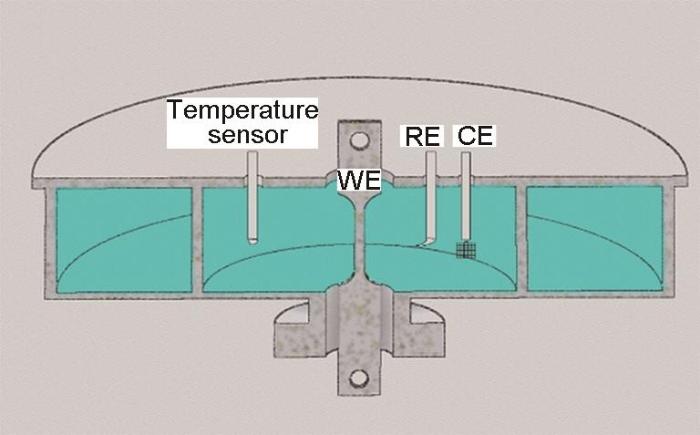

通过Devanathan-Stachurski[19]双电解池装置对试样进行氢渗透实验,其中Ag/AgCl为参比电极,不同区域试样为工作电极,铂网为对电极,装置如图4所示。分别在3种区域切割20 mm × 20 mm × 1 mm大小的试片,随后用150#~2000#的砂纸进行逐级打磨,抛光后对试样阳极侧进行单面电镀,电镀完成后,在阳极氢检测室中加入0.1 mol/L NaOH溶液,利用CS2350型电化学工作站对样品施加(Ecorr + 250 mV)恒定电位,等到阳极电流降至1 μA时,在充氢室加入0.5 mol/L H2SO4和1 g/L Na2S溶液进行电化学氢渗透试验,施加的电流密度为10 mA/cm2,记录阳极室氧化电流随试件的变化情况。

图4

图4

电化学充氢装置示意图

Fig.4

Schematic diagram of electrochemical hydrogen charging device

2 结果与讨论

2.1 氢渗透实验

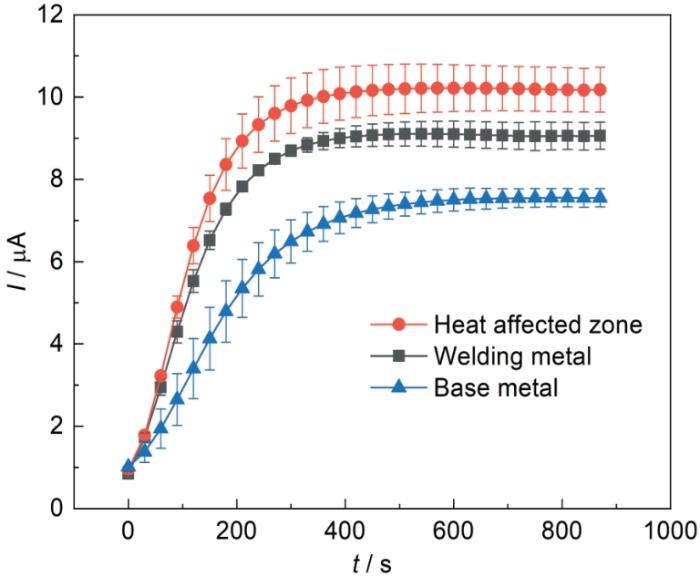

图5为3种区域的氢渗透实验测量结果。图中3条曲线分别代表了母材区、焊缝区和热影响区的渗氢电流随时间的变化情况。从图中可以看出在0~400 s时,3种区域都呈线性上升趋势,表示H从阴极室扩散至阳极室溢出,曲线斜率代表单位时间内扩散到阳极室一侧氢原子数量的多少;随后充氢电流趋于稳定。

图5

图5

焊缝区、热影响区与母材区的氢渗透曲线

Fig.5

Hydrogen permeation curves of the welding metal,heat-affected zone and base metal

根据Fick第一定律可由式(

其中:J∞ 为氢渗透通量,它是单位时间通过单位面积的氢原子数,mol[H]/(cm2·s);D为扩散系数,cm2/s,扩散系数D常被用来表征金属中氢扩散的难易程度,一般认为氢扩散系数大,氢原子在试样内部就越容易聚集导致氢脆的发生;C0表示试样充氢侧表面的氢原子浓度,mol/cm3;L为试样厚度,cm;A为试样面积,cm2,t0.63表示滞后时间,表示(I-I0)/(I∞-I0) = 0.63所对应的时间;NA为Avogadro常数,值为6.02 × 1023 mol-1;D1为无氢陷阱BCC纯铁晶格的扩散系数,值为1.28 × 10-4 cm2·s-1;NT表示氢陷阱密度。通过计算得到3种不同区域的氢扩散参数如表1所示,利用这些参数可以分析氢在材料中的扩散和材料对氢原子的捕获效率。由计算所得数据可以看出热影响区的氢扩散系数大于焊缝区和母材区,氢渗透通量表现出相同的规律。由于氢陷阱会对氢原子在钢中的扩散起阻碍作用,热影响区氢陷阱密度NT最小,所以热影响区扩散系数相对增大。另一方面可能是由于热影响区受高温的影响组织形貌中有少量贝氏体的产生,且热影响区与焊缝区晶粒相对于母材区晶粒粗大导致氢扩散系数增大,氢脆敏感性增强[21]。

表1 焊缝区、热影响区与母材区的氢扩散参数

Table 1

| Zone | I∞ / mA·cm-2 | D / cm2·s-1 | J / mol[H]·cm-2·s-1 | C0 / mol·cm-3 | NT |

|---|---|---|---|---|---|

| Base metal | 7.5 | 8.33 × 10-6 | 7.77 × 10-11 | 9.33 × 10-7 | 2.69 × 1019 |

| Heat-affected zone | 10.2 | 1.28 × 10-5 | 1.06 × 10-10 | 8.25 × 10-7 | 1.49 × 1019 |

| Welding metal | 9.1 | 1.19 × 10-5 | 9.43 × 10-11 | 7.92 × 10-7 | 1.55 × 1019 |

2.2 应力应变曲线

图6分别为母材区、焊缝区和热影响区在不同极化电位下的应力-应变曲线。由图可见,各曲线弹性阶段基本重合一致,屈服强度与极限强度大致相等,3种材料在未充氢情况下的伸缩率明显最高,随着极化电位的减小相同材料的伸缩率呈逐渐减小的趋势。图6d为焊缝区、热影响区和母材区的延伸率随电位变化曲线图。随着施加极化电位的负移,材料延伸率逐渐减小。热影响区在各种电位下的延伸率都为最低。母材区在-1150 mV充氢电位时延伸率为20.1%,焊缝区在-1150 mV充氢电位下的延伸率为19.2%;热影响区在-1150 mV充氢电位时延伸率仅有18.6%。在-1150 mV充氢电位下,热影响区的延伸率最低,说明热影响区在过负的极化电位下表现出的氢脆敏感性最高。氢渗透实验结果得出热影响区的氢扩散系数最高,也就表明在相同的极化电位下,氢在材料内部的扩散更为容易,导致热影响的氢脆效应比其他两个区域更为明显。

图6

图6

母材区、焊缝区和热影响区在不同电位下的应力应变曲线及延伸率曲线

Fig.6

Stress-strain curves of the base metal (a), welding metal (b) and heat-affected zone (c) at different potentials, and their elongation curves (d)

2.3 宏观与微观形貌图

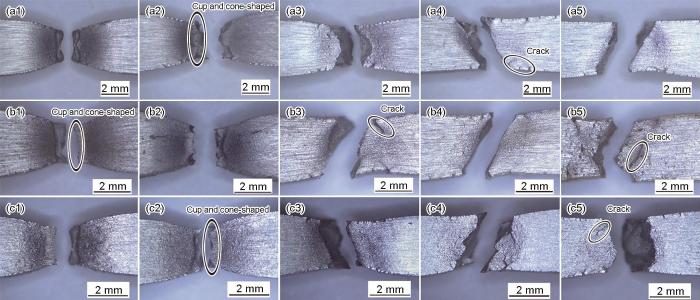

图7为DH36钢3个区域的宏观断口形貌图。由图可见,随着电位的负移,试件的颈缩现象越不明显。在开路电位与-850 mV充氢电位下,3种区域断口处都为杯锥状有剪切唇的特征,表现出明显的韧性断裂。母材区在-950 mV时脆性并不明显,依然有杯锥状断口;焊缝区极化电位在-950 mV时,断口处并无明显的脆断现象,但相比于-850 mV电位下颈缩略微减小,有微小撕裂棱,当电位负于-950 mV时,断口表面出现多处二次裂纹,并伴随有撕裂棱的出现,此时材料为脆性断裂;热影响区在极化电位为-950 mV时,断口处开始出现撕裂棱,材料颈缩已不明显,且在断口附近伴随有许多较长的二次裂纹出现,材料表现为明显的脆性断裂,氢脆敏感性相较于-850 mV大大增加,充氢电位负于-950 mV时,断口平齐,几乎无颈缩现象,并且试样表面有多处长而深的二次裂纹。3种区域在-1050和-1150 mV时断口处有二次裂纹,没有颈缩现象,表现出明显脆性特征。导致此现象的原因可能是随着充氢电位的负移,使得在材料表面富集的氢逐渐增多,导致氢富集处的表面能降低,当外加轴向应力大于材料的临界应力值时,试样表面就会有外裂纹的萌生,而原子将通过应力诱导扩散在裂纹尖端富集,致使氢致裂纹扩展[22]。这与Zucchi等[23]研究结果较为类似,材料在-950 mV将会有氢脆现象的发生,在端口侧面伴随有裂纹的出现。

图7

图7

母材、热影响区与焊缝区宏观断口形貌图

Fig.7

Macroscopic morphologies of fracture surfaces of the base metal (a), heat-affected zone (b) and welding metal (c) with 0 mV (a1-c1), -850 mV (a2-c2), -950 mV (a3-c3), -1050 mV (a4-c4) and -1150 mV (a5-c5)

国内常用氢脆系数(FH)来对比分析不同材料的氢脆敏感性。当氢脆系数FH < 25%,属于安全区;当25% < FH < 35%,属于危险区;FH > 35%,属于脆断区。根据断口大小可以计算材料在不同充氢电位下的氢脆敏感系数。其中:

其中,S0为试样原始截面积,SA为断口部位最小截面积,ψ0为样品在开路电位下的断面收缩率,ψ为试样在溶液中的断面收缩率。计算所得氢脆系数如图8所示,由图可见,当电位为-850 mV时,3种区域的氢脆系数均小于25%,属于安全区。当施加电位为-950 mV时,3种区域的氢脆系数均大于25%,处于氢脆危险区,但热影响区的氢脆系数最大,且接近于脆断区域。在-1050与-1150 mV充氢电位下,3种区域的氢脆系数均大于60%,说明材料在负于-1050 mV时,3种区域都处于严重脆断区,氢脆敏感性增强。随着极化电位的负移,氢脆系数逐渐增大,氢脆系数在各个充氢电位下热影响区>焊缝区>母材区。

图8

图8

焊缝区、热影响区和母材区氢脆系数

Fig.8

Hydrogen embrittlement coefficients of the welding metal, heat-affected zone and base metal

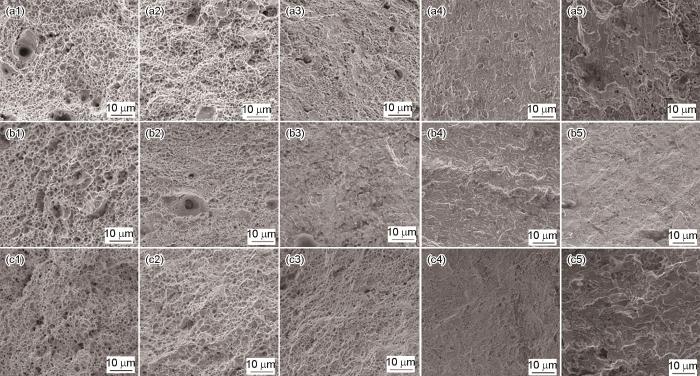

图9为在不同电位下3种区域的微观断口形貌图。从图可见,在开路电位以及-850 mV的充氢电位下,3种材料组织形貌以大小不等的韧窝为主,表现为韧性断裂;在-950 mV的充氢电位下热影响区为准解理断裂特征,母材区与焊缝区表现出混合断裂特征;在-1050与-1150 mV的充氢电位下3种区域均呈现出大量的河流状花纹,解理组织部分增多,属于脆性断裂特征。热影响区的脆性明显高于焊缝区域与热影响区,由于金相中显示,热影响区是由铁素体与贝氏体组成,研究表明[24],因为氢致裂纹萌生主要发生在树枝状共析铁素体和贝氏体铁素体之间的界面,并与树枝状铁素体一起扩展,其中应力/应变不相容性和局部变形促进了氢的扩散,导致了材料氢脆现象更加明显。

图9

图9

母材、热影响区和焊缝区在不同电位下拉伸断口形貌图

Fig.9

Microscopic morphologies of fracture surfaces of the base metal (a), heat-affected zone (b) and welding metal (c) with 0 mV (a1-c1), -850 mV (a2-c2), -950 mV (a3-c3), -1050 mV (a4-c4) and -1150 mV (a5-c5) after tensile test at different potentials

3 结论

(1) DH36钢母材区的氢扩散系数为8.33 × 10-6 cm2/s,焊缝区域的氢扩散系数为1.19 × 10-5 cm2/s,热影响区的氢扩散系数为1.28 × 10-5 cm2/s,热影响区的氢扩散系数最大。由于热影响区受高温的影响,组织形貌中有少量贝氏体的产生,且热影响区晶粒相对粗大,缩短氢的扩散距离,使氢的扩散更加容易,扩散系数增大。

(2) 在不同的极化电位下,3种区域的屈服强度、极限强度并无明显的变化,随着施加极化电位的负移,材料延伸率逐渐减小。热影响区在各种电位下的延伸率都为最低。氢渗透实验中,热影响区的扩散系数最大,氢在热影响区内部的扩散更为容易,说明热影响区受氢的影响最大,从而导致其延伸率最小。

(3) 随着充氢电位的减小,氢脆系数会逐渐增大,材料韧性降低,氢脆敏感性增加,各极化电位下的氢脆系数热影响区>焊缝区>母材区。热影响区在极化电位为-950 mV表现出脆断特征,可能与热影响区中含有少量贝氏体有关。

参考文献

Current situation and prospect of studies on strength and corrosion resistance of high strength steel for ocean platform

[J].

海洋平台用高强钢强度及其耐蚀性现状及发展趋势

[J].

Research progress in cathodic protection technology for marine infrastructures in deep sea environment

[J].

深海工程装备阴极保护技术进展

[J].

Comparison of hydrogen embrittlement susceptibility of three cathodic protected subsea pipeline steels from a point of view of hydrogen permeation

[J].

On the suitability of slow strain rate tensile testing for assessing hydrogen embrittlement susceptibility

[J].

Investigation on hydrogen-induced cracking behavior of 2205 duplex stainless steel used for marine structure

[J].

海工结构用2205双相不锈钢氢致开裂行为研究

[J].模拟了海工结构的2205双相不锈钢钢筋 (A-DSS和B-DSS) 在人工海水中不同条件下的服役行为。通过D-S双电解池氢渗透技术测试了氢在两种钢筋中的扩散行为。通过慢应变速率拉伸实验,结合SEM观察,研究了钢筋在空气以及人工海水中的拉伸断裂行为,分析了阴极极化对断裂行为的影响。结果表明,氢在A-DSS和B-DSS两种钢筋中的扩散系数D分别为2.36×10<sup>-10</sup>和2.31×10<sup>-10</sup> cm<sup>2</sup>/s。当A-DSS和B-DSS在人工海水中外加阴极极化电位分别为-800和-700 mV (SCE) 时,两种钢筋的环境断裂敏感性最低。利用SEM观察了在外加电位下断裂试样的表面形貌,可观察到表面裂纹在铁素体相中萌生并扩展,终止于奥氏体相或两相界面。

Susceptibility to hydrogen embrittlement of X65 steel under cathodic protection in artificial sea water

[J].

阴极保护下X65钢在模拟海水中的氢脆敏感性研究

[J].采用阴极极化条件下的氢渗透实验和慢应变速率拉伸实验研究了X65钢在模拟海水中的氢渗透行为及其对断裂机理的影响。氢渗透实验结果表明,阴极极化过程中试样表面的钙镁沉积层能显著地降低氢扩散系数,采用Fourier方程、Laplace方程以及时间滞后法计算得出的有效氢扩散系数平均值为1.49×10<sup>-</sup><sup>7</sup> cm<sup>2</sup>s<sup>-</sup><sup>1</sup>。结合变电位极化氢渗透测试结果、拉伸试样断口分析以及极化曲线测试,对阴极极化条件下X65钢的氢脆敏感性进行评估。结果显示,随着极化电位的降低,X65钢中的吸附氢浓度呈指数规律上升。当极化电位较高时,X65钢的裂纹扩展受阳极溶解和阴极析氢的双重作用控制。当极化电位较低,如-1200 mV时,钢中的吸附氢浓度急剧增加,脆性断裂区域的比例上升,X65钢发生氢致脆化失效。

Hydrogen embrittlement sensitivity of 10Ni5CrMo steel at different temperatures and polarization potentials

[J].

温度及极化电位对10Ni5CrMo钢氢脆敏感性的影响

[J].

Effect of strain rate on hydrogen embrittlement susceptibility of DP780 steel with hydrogen pre-charging

[J].

应变速率对预充氢DP780钢氢脆敏感性的影响

[J].

Hydrogen embrittlement behavior of BS960E high strength steel laser-arc hybrid welded joint

[J].

BS960E高强钢激光-电弧复合焊接头氢脆行为研究

[J].

Comparative study on hydrogen embrittlement susceptibility of X60 and X70 pipeline steels and their welded joints

[J].

X60、X70管线钢及其焊接接头氢脆敏感性的对比研究

[J].

Hydrogen embrittlement susceptibility of welded 2¼Cr-1Mo steel under elastic stress

[J].

Investigation of hydrogen-induced cracking susceptibility of X90 pipeline steel welded joints

[J].

X90管线钢焊接接头氢致开裂敏感性研究

[J].

Hydrogen embrittlement of X2CrNiMoCuN25-6-3 super duplex stainless steel welded joints under cathodic protection

[J].

Effect of microstructure inhomogeneity on hydrogen embrittlement susceptibility of X80 welding HAZ under pressurized gaseous hydrogen

[J].

Effects of cathodic polarization on the hydrogen embrittlement sensitivity of welding line in high strength hull structural steel

[J].

阴极极化对高强度船体结构钢焊缝氢脆敏感性的影响

[J].在恒定阴极电位下利用慢应变速率拉伸试验研究高强度船体结构钢焊缝的电化学性能和力学性能。结果表明,试样拉伸断裂主要发生在焊缝的熔合区;结构钢的阴极极化程度对抗拉强度和屈服强度的影响不大;随阴极电位负移,船体结构钢在海水中的延伸率、断裂时间和断裂应变率逐渐减小, 并且当施加阴极电位为-0.89 V(vs SCE)时各项性能最佳。同时,随着阴极电位负移,断裂方式逐渐从韧性断裂向脆性断裂发展,氢脆敏感性逐渐增加,在 -0.70 V~-0.89 V(vs SCE)之间氢脆敏系数低于5%,不发生氢脆;当电位负于-0.94 V(vs SCE),氢脆敏感性迅速提高,当极化电位为-0.99 V (vs SCE)时氢脆系数显著增大至20%,断口开始出现解理单元细小准解理断裂特征;在负于-1.04 V(vs SCE)时,氢脆系数已高于25%,进入危险区,且断口开始出现较多解理单元粗大的准解理、解理等氢脆断裂特征;随着电位继续负移至-1.14 V(vs SCE),断口完全出现解理组织、沿晶、穿晶结构或者两者混合的氢脆断裂特征。

Numerical interpretation to differentiate hydrogen trapping effects in iron alloys in the Devanathan-Stachurski permeation cell

[J].

Hydrogen permeation behavior of X80 steel under cathodic polarization and stress

[J].

阴极极化和应力耦合作用下X80钢氢渗透行为研究

[J].

Study on microstructure and hydrogen permeation behavior of welding heat affected zone of X80 pipeline steel

[J].

X80管线钢焊接热影响区组织和氢渗透行为研究

[J].

Effect of cathodic polarization on hydrogen embrittlement susceptibility of X80 pipeline steel in simulated deep sea environment

[J].<p>Pipeline steels utilized in deep seawater are usually protected cathodically. However, inappropriate operations of cathodic protection systems cause hydrogen embrittlement failures to these high strength steels in seawater which result from the application of excessive negative potentials, leading to massive generation of hydrogen at the protected pipelines' surface. With high strength steels increasingly widely used in the deep sea environment, the basic research to the cathodic protection and susceptibility to hydrogen embrittlement of high strength steels under such a circumstance is still unfortunately relatively lack and urgently needed to supplement. Electrochemical measurement, hydrogen permeation current detection, slow strain rate tensile test (SSRT) and fracture morphology analysis, therefore, were employed to investigate effect of cathodic polarization level on the susceptibility of API X80 pipeline steels to hydrogen embrittlement in simulated deep seawater in the present work. The results showed that the applied cathodic polarization potentials significantly affected hydrogen permeation and hydrogen--induced cracking behavior of X80 steels immersed in deep seawater. A linear relationship was found between the hydrogen permeation current densities and cathodic polarization potentials applied according to the findings of the potential dynamic polarization and hydrogen permeation current measurements. SSRT tests suggested that X80 pipeline steels immersed in simulated deep seawater didn't show susceptibility to hydrogen embrittlement at open circuit potential, and thus the optimum cathodic protection potential range was supposed to be above -900 mV (<em>vs</em> saturated calomel electrode). Under such a cathodic polarization potential, the hydrogen permeation current densities of X80 pipeline steel specimens were less than 0.1157 <em>μ</em>A/cm<sup>2</sup> andtheir mechanical properties didn't decrease remarkably. Once the cathodic polarization potentials lower than -900 mV, however, hydrogen permeation current densities and calculated hydrogen embrittlement coefficients <em>ψ</em> of X80 pipeline steels increased significantly, exhibiting higher susceptibility to hydrogen embrittlement in simulated deep seawater. Furthermore, macro-and micro-morphologies of fracture surface of X80 pipeline steels after SSRT test indicated that the fracture morphology transformed from a dimpled pattern with ductile fracture to a quasi—cleavage pattern when cathodically polarized to lower than -900 mV, <em>i.e.</em> showing obvious brittle failure characteristics.</p>

阴极极化对管线钢在模拟深海条件下氢脆敏感性的影响

[J].

Hydrogen embrittlement of duplex stainless steel under cathodic protection in acidic artificial sea water in the presence of sulphide ions

[J].

Hydrogen embrittlement susceptibility of X70 pipeline steel weld under a low partial hydrogen environment

[J].