但在生产加工以及服役过程中,钛合金表面钝化膜的破坏难以避免,耐蚀性能受到极大损害。

综上,本研究以TC4合金为研究对象,以NaOH为溶质配置质量分数为10%的洗涤液,对TC4合金表面钝化膜的溶解-修复平衡机制进行扼要讨论。以工业自来水和去离子水为改良清洗剂,并在50~80 ℃温度区间内对TC4合金部件进行清洗实验,选取清洗温度为55,65,75 ℃的样品进行水洗痕迹产生机理的分析。

1 实验方法

实验所选的合金为TC4合金,名义成分(质量分数,%)为:Al 5.5~6.8,V 3.5~4.5,Fe ≤ 0.30,O ≤ 0.20,C ≤ 0.10,N ≤ 0.05,H ≤ 0.015,Ti余量。

水洗液为工业自来水和去离子水,碱性洗剂成分为10% (质量分数) NaOH溶液。

实验所采用的TC4合金样品为正火态,采用激光切割的方法从发动机零部件切割下来,随后用无水乙醇擦拭干净备用。通过光学显微镜和Nano SEM430场发射扫描电子显微镜(FESEM)对洗涤后的样品进行微观形貌的分析,通过其配备的能谱仪(EDS)分析洗涤前后样品成分变化。为进一步分析水洗过程中TC4合金腐蚀行为,使用CHI-660E电化学工作站,以洗剂为电解质,饱和甘汞电极为参比电极,尺寸为1 cm × 1 cm的铂片为辅助电极。

2 结果与分析

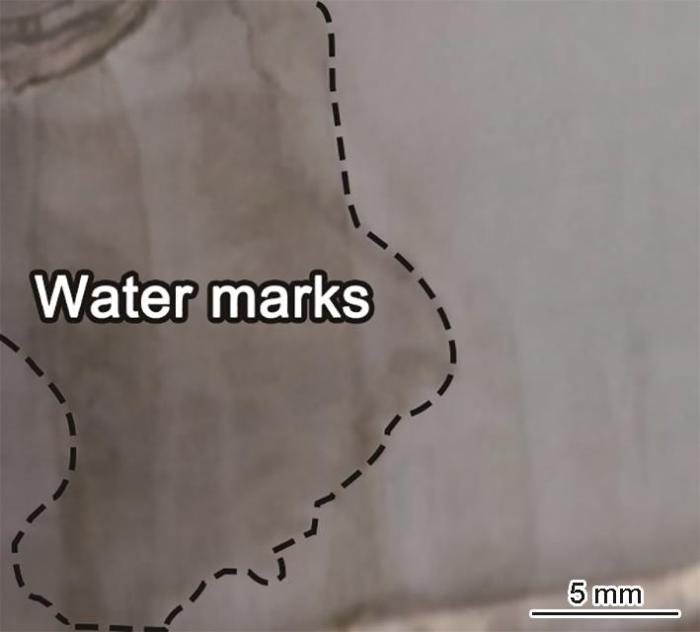

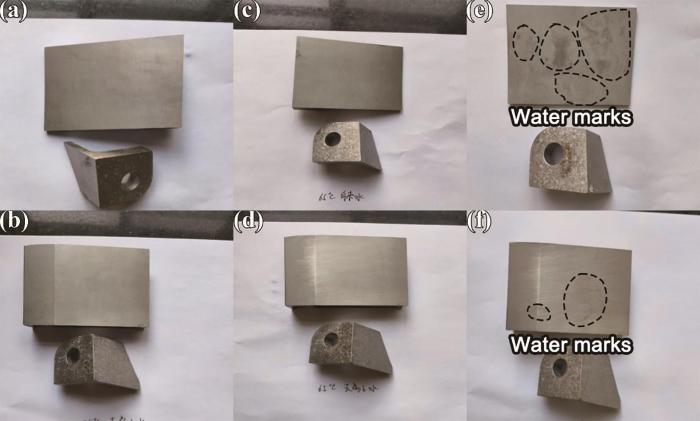

图1

图1

TC4合金部件在10%NaOH洗涤后留痕宏观形貌

Fig.1

Macroscopic morphology of a TC4 alloy parts after washing with 10%NaOH solution

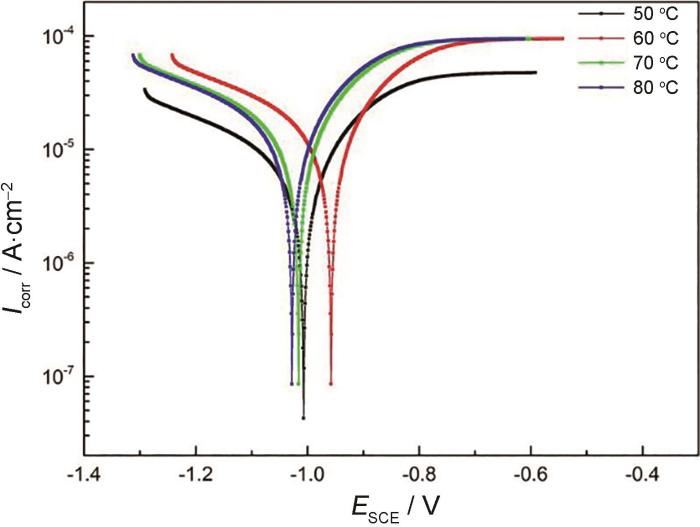

表1 不同温度下TC4合金极化曲线的拟合结果

Table 1

| Temperature / oC | Ecorr / V | Icorr / A·cm-2 |

|---|---|---|

| 50 | -0.993 | 6.381 × 10-6 |

| 60 | -0.962 | 1.673 × 10-5 |

| 70 | -1.026 | 1.821 × 10-5 |

| 80 | -1.067 | 2.219 × 10-5 |

图2

图2

TC4合金在50~80 ℃下10%NaOH溶液中的极化曲线

Fig.2

Polarization curves of TC4 alloy in 10%NaOH solution at 50~80 oC

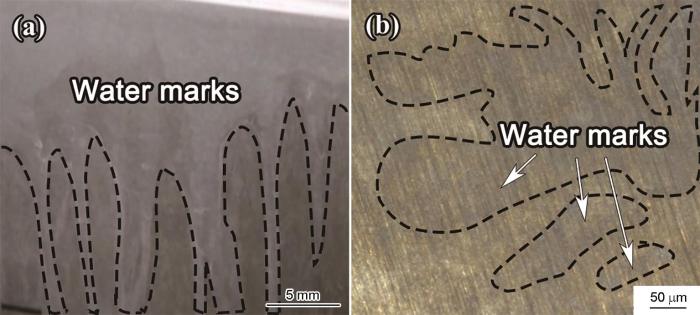

为进一步分析留痕的微观形貌,选取留痕较为严重的部分,进行宏观形貌观察及电子显微分析。图3留痕处宏观及光学显微分析结果表明,该零件在碱洗后表面痕迹严重,水洗痕迹位置与周围组织单纯存在明显颜色差异,表面加工痕迹在碱洗留痕处发生腐蚀,与周围原始组织存在明显差异。当零件脱离清洗溶液进入空气中时,零件表面各部分降温速度不同,相应表面干燥速度不同,从而使基体金属同外界空气接触氧化反应速度不同,即新的钝化平衡产生的速度不同,表观反映为出现颜色不一致的花纹状态,且温差越大,该现象越为明显。

图3

图3

TC4合金洗涤留痕痕迹宏观照片和光学照片

Fig.3

Macroscopic photo (a) and optical microscope morphology (b) of residual traces on TC4 alloy after washing

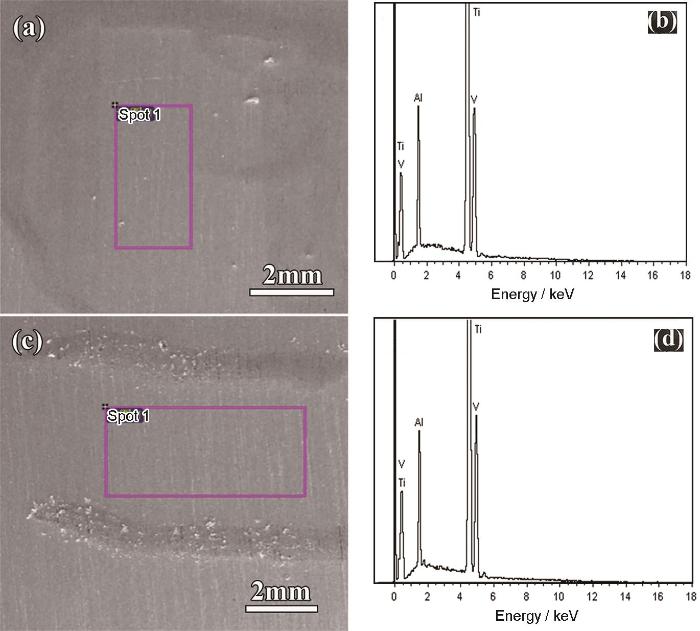

图4a,c为碱洗后TC4合金留痕处及TC4合金基体的微观形貌,从其微观形貌可知,留痕处周围基体间存在明显的衬度差异,留痕处呈现深灰色衬度,表明TC4合金在碱洗过程中发生了腐蚀,其反应方程式如下:

图4

图4

碱洗后留痕处形貌和基体的形貌,留痕处元素分析与基体元素分析

Fig.4

Surface morphologies (a, c) and element analysis results (b, d) of the marked zones for residual trace and matrix after alkaline washing, respectively

由于在碱洗后干燥的过程中,会有部分碱液残留在表面,这部分碱液由于水分蒸发而浓度上升,而钛合金表面的钝化膜在高浓度的碱液中反应溶解,因此发生了腐蚀出现了与基体不同衬度的留痕。且由于其腐蚀产物可溶于水,残留较少,因此在图4中未出现明显的元素成分差异。

3 工艺改进

根据碱洗留痕产生的机理性分析,可制定两项改进措施,首先是在工艺范围内降低操作温度,以确保零件出槽后有充分时间进行清洗降温,并保证工序间湿润,水膜的附着可有效避免材料的变色。其次是采用去离子水以及工业自来水清洗零件,降低洗剂pH从而避免TC4合金在碱性电解质中的电化学腐蚀,比照验证改进措施的有效性。

图5

图5

TC4合金碱洗后分别用55,65,75 ℃自来水和55,65,75 ℃去离子水清洗后的宏观形貌

Fig.5

Macro-morphologies of alkaline washed TC4 alloy after cleaning with tap water (a, c, e) and deionized water (b, d, f) at 55 oC (a, b), 65 oC (c, d) and 75 oC (e, f)

由此可以看出,大型耐蚀性较差的TC4合金零件在清洗过程中清洗温度不宜过高,一方面保证零件出槽液后可以及时清洗,避免零件污染,一方面保证有水膜的隔绝,避免大型零件快速干燥过程中,表面钝化膜产生不均匀,从而产生水洗留痕。

4 结论

(1) TC4等大型钛合金零件碱洗留痕的产生是由于表面钝化膜被腐蚀造成的。

(2) 采用较低温度如55 ℃工业自来水清洗零件,可有效避免由于大型零件干燥速度不一致而产生水洗留痕。

(3) 采用去离子水清洗钛合金零件可以进一步提高清洗质量。

参考文献

Insight into behavior and mechanism of passivation of titanium and titanium allosy

[D].

钛/钛合金钝化行为与机理研究

[D].

The formation of α + β microstructure in as-fabricated selective laser melting of Ti-6Al-4V

[J].

Research progress and application of titanium alloys

[J].

钛合金的研究进展与应用

[J].

Electrochemical behaviour of passive film formed on the surface of Ti-6Al-4V alloys fabricated by electron beam melting

[J].

XPS and EIS study of the passive film formed on orthopaedic Ti-6Al-7Nb alloy in Hank's physiological solution

[J].

Passive film-induced stress and mechanical properties of α-Ti in methanol solution

[J].

Electrochemical corrosion of titanium and titanium alloys anodized in H2SO4 and H3PO4 solutions

[J].

Oxide film growth kinetics on metals and alloys: I. Physical model

[J].

Study on the mechanism of porosity formation and laser fusion welding technology of commercial pure titanium

[J].

工业纯钛激光自熔焊接工艺及气孔形成机理研究

[J].

Corrosion performance of titaniun alloy

[J].

SST-861钛合金阳极的腐蚀特性及钝化膜表征

[J].

Corrosion characteristics and applications of titanium and titanium alloys

[J].

钛及钛合金的腐蚀特性和应用

[J].

Review on cutting tool and processing technology for titanium alloy aviation components

[J].

钛合金航空结构件加工刀具与工艺技术研究现状

[J].

Enhanced strength-ductility synergy in laser additive manufactured TC4 titanium alloy by grain refinement

[J].

Study on surface properties of Ti-6Al-4V titanium alloy by ultrasonic rolling

[J].

Corrosion behavior of near-alpha titanium alloy fabricated by additive manufacturing

[J].

Evaluation of the stress corrosion cracking susceptibility of titanium alloys and welded joints

[J].

Atomic layer deposited transition metal oxide-titania alloys as corrosion resistant schottky contacts for silicon photoanodes

[J].

Corrosion and tensile behaviors of Ti-4Al-2V-1Mo-1Fe and Ti-6Al-4V titanium alloys

[J].