近年来,已有很多研究表明通过微合金元素添加可改善SASSs凝固组织均匀性,抑制有害相的析出。如添加极少量的B (0.002%~0.005%,质量分数),对SASSs的析出相有明显的抑制作用[7~9]。本课题组在之前的研究[10~13]中观察到,S31254超级奥氏体不锈钢(简称S31254不锈钢)中加入微量(0.004%,质量分数)的B可在固溶阶段加速σ相的回溶,并抑制热加工变形阶段σ相在原始及再结晶晶界的大量析出,促进再结晶晶粒的长大,从而改善热塑性。B还可以提高S31254不锈钢的抗点蚀能力,提高钝化膜中Cr2O3的含量,增加钝化膜的致密性[10, 11]。此外,稀土Ce的添加能净化晶界、细化晶粒、改善元素偏析,净化夹杂物[14,15]。Wang等[16]研究表明0.016%(质量分数)Ce的添加,可抑制Mo、Cr的晶界偏析,延缓并减少σ相的析出,同步提升S31254的热加工和耐蚀性能。微量Ce可以抑制铸态组织中Cr和Mo的凝固偏析[17]。Sun等[18]通过研究稀土Ce对双相不锈钢中的析出行为的影响,结果表明少量(0.0055%和0.01%,质量分数) Ce的添加可以有效地抑制σ相的析出。

现有研究结果来看,B、Ce对SASSs析出及耐蚀的影响往往是单一元素的影响,B与稀土Ce复合微合金化对于S31254不锈钢的析出行为及耐蚀性影响,尤其B、Ce间配比的影响仍不明晰。因此,本研究将对比分析不含B和Ce (0B)、B微合金化(50B)以及B-Ce复合微合金化(50B-20Ce和50B-50Ce)的4种成分的S31254不锈钢,通过研究B、Ce配比对超奥钢Cr、Mo的晶界偏析,第二相析出的影响,探究B、Ce协同对S31254不锈钢中σ相的析出行为以及微观组织、耐蚀性能的影响规律。

1 实验方法

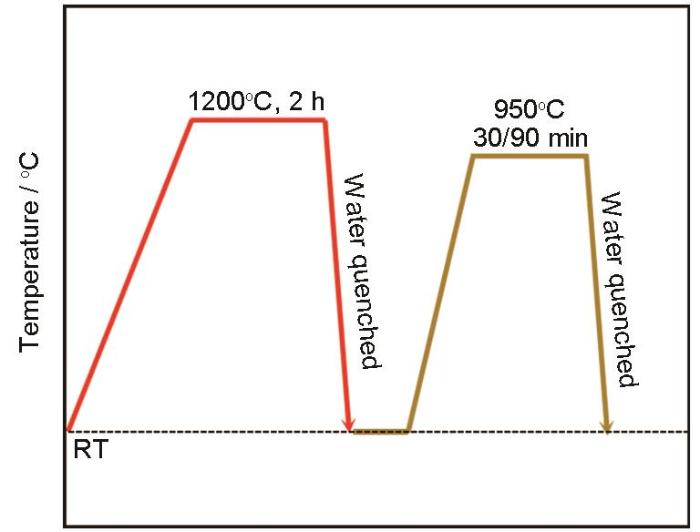

实验用超级奥氏体不锈钢在S31254不锈钢成分基础上添加了0.005% (质量分数,下同)的B、0.002%和0.005%的Ce,对应4种成分超奥钢分别标为0B、50B、50B-20Ce、50B-50Ce,在真空感应炉中进行冶炼,随后使用KSL-1500X型马弗炉在1200℃保温10 h对铸坯进行均质化处理,最后对均质化板材进行热轧,轧制变形量为60%,轧制温度为1200℃,实验用合金的主要化学成分如表1所示。轧制好的实验钢板采用DK77-20型电火花线切割机切割成15 mm × 15 mm × 2 mm试样,对表面均匀涂抹防氧化液后进行固溶及时效处理,固溶处理温度为1220℃,保温2 h。因S31254不锈钢的析出鼻尖温度约为950℃[5,6],为研究合金元素添加对析出规律的影响,固时效处理选择在950℃管式炉中进行,时效时间分别为30和90 min,随后进行水淬。热处理工艺过程如图1所示。

表 1 实验用S31254不锈钢化学成分 (mass fraction / %)

Table 1

| Sample | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N | B | Ce |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0B | 0.012 | 0.64 | 0.47 | 0.035 | 0.006 | 19.18 | 18.11 | 6.17 | 0.71 | 0.20 | 0 | 0 |

| 50B | 0.012 | 0.61 | 0.49 | 0.017 | 0.005 | 18.59 | 18.11 | 6.12 | 0.58 | 0.20 | 0.005 | 0 |

| 50B-20Ce | 0.018 | 0.17 | 1.82 | 0.007 | 0.002 | 19.84 | 18.07 | 6.21 | 0.56 | 0.199 | 0.005 | 0.002 |

| 50B-50Ce | 0.015 | 0.17 | 1.87 | 0.008 | 0.002 | 20.08 | 17.94 | 6.02 | 0.48 | 0.187 | 0.005 | 0.005 |

图1

图1

热处理工艺示意图

Fig.1

Schematic illustration of the heat treatment schedule employed in this study

将固溶处理、时效处理后的试样粗磨(120~3000#),并使用金刚石研磨膏(1.5 µm)抛光,随后使用王水腐蚀。显微组织观察前采用无水乙醇对试样进行超声波清洗500 s。随后使用光学显微镜、扫描电子显微镜(SEM, JEOL 7900 F)和能谱仪(EDS, Ultim Extreme )对材料进行表征。

采用三电极体系,在模拟烟气脱硫冷凝液(11.5%(质量分数,下同)H2SO4 + 1.2%HCl + 1.0%FeCl3 + 1.0%CuCl2)中进行电化学测量,使用饱和汞电极(SCE)作为参比电极(RE),铂片作为对电极(CE),长宽尺寸为20 mm × 20 mm,工作电极为实验钢,长宽尺寸为10 mm × 10 mm。电化学容器放置水浴锅中,温度控制在30℃。在腐蚀实验之前,在-1.0 VSCE下进行阴极极化5 min,去除表面钝化膜。然后,将工作电极在电解质中稳定30 min以达到稳定状态。随后开始电化学测试,记录极化曲线。极化后,在相同溶液中进行电化学阻抗谱(EIS)分析, 阻抗实验用材料先在50 mVSCE恒电位条件极化反应2 h。每个实验测试3次。为了进一步研究B、Ce对超奥钢耐蚀性能的影响,后续采用硫酸-硫酸铁浸泡实验对0B、50B、50B-20Ce、50B-50Ce固溶试样的耐腐蚀性能进行评价。

2 结果与讨论

2.1 微观组织分析

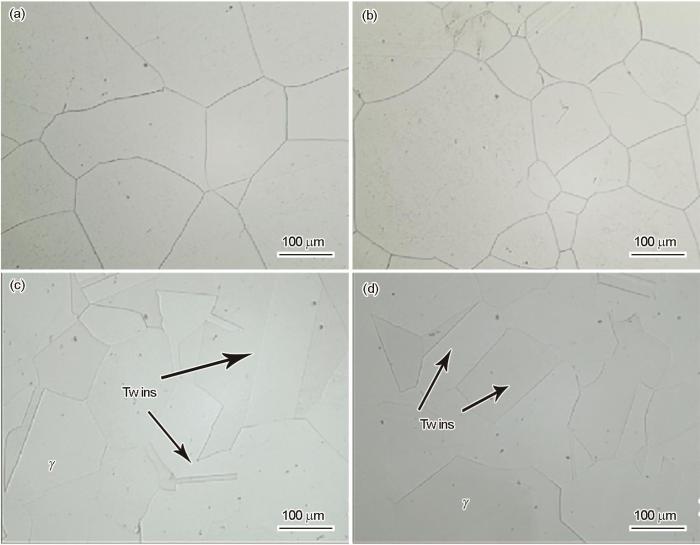

图2

图2

4种S31254不锈钢经1220℃保温2 h固溶处理后的显微组织

Fig.2

Microstructures of four S31254 stainless steels after solution treatment at 1220oC for 2 h: (a) 0B, (b) 50B, (c) 50B-20Ce, (d) 50B-50Ce

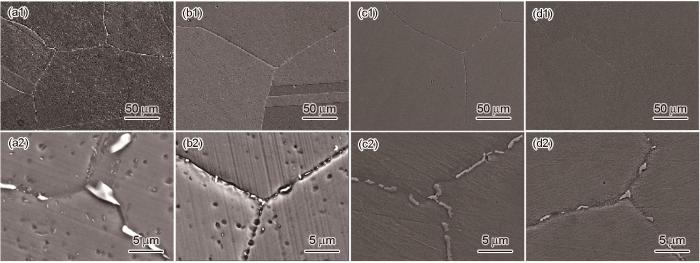

为了进一步研究B、Ce微合金化对S31254不锈钢析出相析出行为的影响,对0B、50B、50B-20Ce和不锈钢50B-50Ce 共4种试样进行950℃,90 min时效处理。图3为4种不同成分的试样在950℃时效后的SEM图。可以看出,在相同时效条件下,B、Ce微合金化后的试样晶界及晶内析出相明显减少,尤其是B-Ce复合添加更有利于抑制σ相的析出。如图3a所示,0B实验钢中晶界和晶内均有析出,析出相沿着晶界处几乎连成网状,在三角晶界处的析出相尺寸更大。添加B后,50B钢时效后,晶界上的析出相数量较少,尺寸较小,并且晶内仍有析出相析出,如图3b所示。50B-20Ce试样中,析出相数量明显减少(图3c),在晶界的析出相较为细小、σ相断续分布于晶界。同时,晶内析出也得到了明显的抑制。50B-50Ce试样中析出相数量更少,在晶界上析出相较50B-20Ce试样更为细小、更断续,如图3d所示。以上结果表明,B、Ce复合添加对于950℃时效析出相的形成抑制作用更明显,且Ce含量的提高对晶界上析出相抑制效果更为显著。

图3

图3

4种S31254不锈钢经950℃时效90 min后的SEM图

Fig.3

Microstructures of four S31254 stainless steels after aging at 950oC for 90 min: (a1, a2) 0B, (b1, b2) 50B, (c1, c2) 50B-20Ce, (d1, d2) 50B-50Ce

S31254不锈钢在950℃时效的析出相是σ相,众所周知,σ相是一种富Cr、富Mo的金属间化合物[19]。另一方面,晶界是高能量的区域,Mo、Cr等合金元素在晶界上易富集,并沿晶界扩散,因此析出相会优先沿晶界形核长大。通过SEM-EDS对析出相的形成所引起的元素富集进行探究。图4分别为0B、50B、50B-20Ce和50B-50Ce试样950℃时效90 min后,晶界处析出相的元素分布图。表2所示为对应实验钢析出相中的元素含量分析。对于0B样品(图4a),可以看出,晶界的析出物主要富集Cr和Mo。标记部分(1、2点位)为晶界析出元素明显富集的位置,其中Cr的质量分数分别为26.7%和25.6%,Mo的质量分数为22.31%和21.8%,对应是σ相。对于50B试样(图4b),可以看出在晶界处元素富集主要是Mo,而Cr分布相对均匀,并且在晶界处的析出物中可以观察到少量的B偏析。根据EDS结果,在晶界中元素富集明显的位置,Cr含量为23%左右,Mo含量为23%~25%。对于50B-20Ce样品(图4c),可以看出,晶界处的析出物主要富集Cr和Mo,B也有少量偏析,同时,在晶界处元素明显富集的位置,Cr的质量分数为25%~27%,Mo的质量分数为16%~18%。对于50B-50Ce样品(图4d),可以看出在晶界处元素富集主要是Mo,并且在晶界处析出物中可以观察到少量的B和Ce偏析。晶界处元素富集明显的位置,Cr含量仅为20%~21%,与基体中Cr含量(20%)接近,Mo含量为15%~16%。由以上分析可知,随着Ce含量的增加,析出相中Mo与Cr含量显著降低,B、Ce复合更有利于减缓贫Cr区的形成,抑制Cr、Mo在晶界的聚集。

图4

图4

4种S31254不锈钢在950℃时效90 min试样的EDS面扫图

Fig.4

EDS elemental mappings of four S31254 stainless steels aged at 950oC for 90 min: (a) 0B, (b) 50B, (c) 50B-20Ce, (d) 50B-50Ce

表2 4种S31254不锈钢在950℃时效90 min后析出相的化学成分 (mass fraction / %)

Table 2

| Position | Fe | Cr | Mo | Ni |

|---|---|---|---|---|

| 0B-1(Fig. | 39.2 | 26.7 | 22.3 | 8.1 |

| 0B-2(Fig. | 44.5 | 25.6 | 21.8 | 8.1 |

| 50B-1(Fig. | 38.7 | 22.9 | 24.6 | 9.9 |

| 50B-2(Fig. | 39.8 | 22.8 | 22.7 | 10.8 |

| 50B-20Ce-1(Fig. | 39.6 | 26.1 | 17.8 | 9.1 |

| 50B-20Ce-2(Fig. | 40.2 | 25.7 | 16.6 | 9.4 |

| 50B-50Ce-1(Fig. | 42.5 | 20.6 | 15.3 | 9.7 |

| 50B-20Ce-2(Fig. | 42.4 | 20.2 | 15.7 | 10.6 |

2.2 耐蚀性能分析

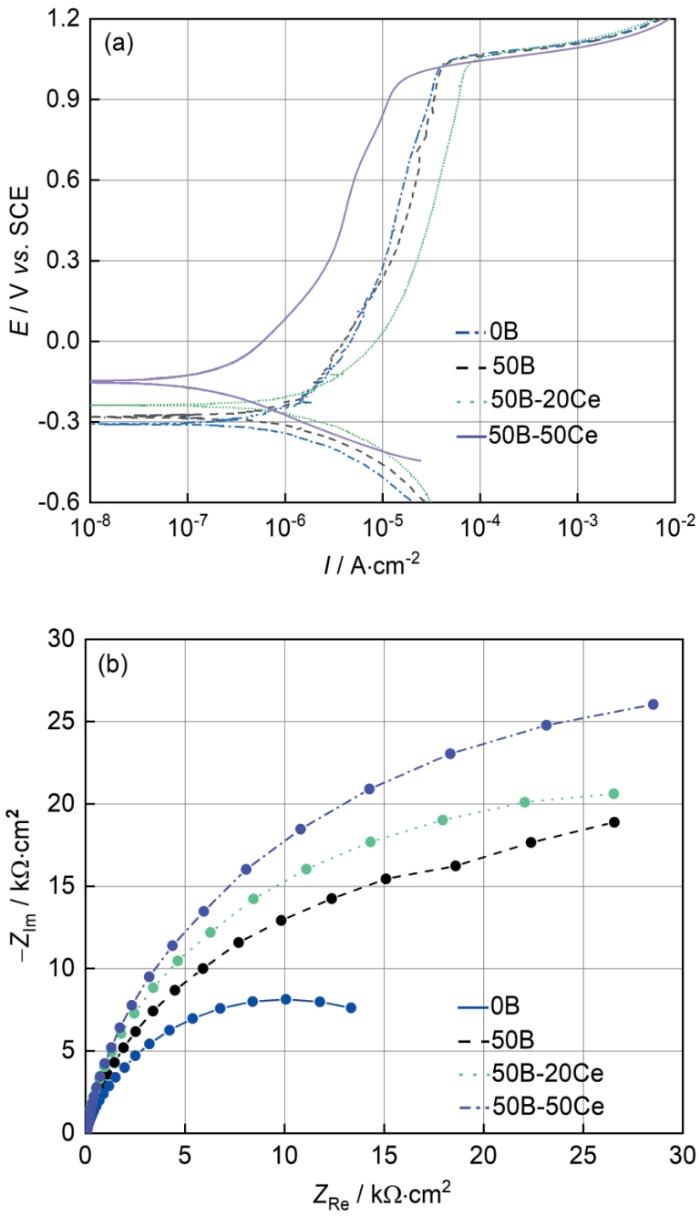

通过电化学测试分析比较了4种不同成分S31254不锈钢在950℃时效30 min后试样的耐蚀性。图5a为4种实验钢经过950℃时效30 min后,在模拟烟气脱硫冷凝液中测得的极化曲线。可以看出,测试曲线的阳极分支表现出明显的自钝化特征[11]。对极化曲线进行拟合,得到相应的电化学参数,如表3所示。自腐蚀电位(Ecorr)和腐蚀电流密度(Icorr)通常用于表征材料钝化膜的溶解能力,而点蚀电位(Epit)代表试样在腐蚀过程中钝化膜被击穿时的电位,点蚀电位越高,则材料所形成的钝化膜更加稳定[20]。0B的Ecorr为-0.3076 V,加入B后,50B试样的Ecorr升高,Icorr降低,Epit提高,腐蚀速率减慢,耐蚀性随着B的加入明显提高。B、Ce复合后,50B-20Ce和50B-50Ce试样的Ecorr比50B试样更高,Icorr降低,腐蚀速率也进一步减慢,Epit同步提高,其中50B-50Ce试样耐蚀性更为优异。这说明B、Ce复合添加的试样具有更好的耐蚀性,且Ce含量提高,改善耐蚀性效果更为明显。

图5

图5

4种S31254不锈钢经950℃时效30 min后的动电位极化曲线和阻抗谱

Fig.5

Potentiodynamic polarization curves (a) and EIS (b) of four S31254 stainless steels after aging at 950oC for 30 min

表3 4种S31254不锈钢经950℃时效30 min后的动电位极化曲线拟合参数

Table 3

| Sample | Ecorr / V | Icorr / A·cm-2 | Epit / V |

|---|---|---|---|

| 0B | -0.3076 | 7.4063 × 10-7 | 0.9791 |

| 50B | -0.2806 | 5.6066 × 10-7 | 1.0264 |

| 50B-20Ce | -0.2376 | 4.3216 × 10-7 | 1.0284 |

| 50B-50Ce | -0.1506 | 1.0656 × 10-7 | 1.0319 |

为了深入研究4种不同成分S31254不锈钢在模拟烟气脱硫环境中形成钝化膜的特性,进一步对试样进行EIS测试,其结果见图5b。Nyquist图中,容抗弧的半径越大,代表钝化膜的稳定性越高,材料的钝化膜越致密,耐蚀性能越好[21]。从图5b中可以看出,4种试样时效后的容抗弧均为向内凹的半圆形圆弧,说明实验中的腐蚀机制相同。0B钢中加入B后,容抗弧半径逐渐增大,说明钝化膜的稳定性逐渐增强,耐蚀性提高。B、Ce复合添加后,50B-20Ce、50B-50Ce的容抗弧半径均大于0B和50B试样,且50B-50Ce的容抗弧半径最大,说明B、Ce协同可以改善表面钝化膜的致密性与稳定性,改善其耐蚀性能,且Ce含量增加,对钝化膜稳定性及耐蚀性提高效果更为明显。这与图5a动电位极化曲线的测试结果一致。

为了进一步研究B、Ce微量添加对S31254不锈钢耐蚀性能的影响,本研究采用沸腾硫酸铁-硫酸浸泡腐蚀法对不同成分S31254不锈钢的耐蚀性能进行了分析。图6为4种试样的腐蚀形貌。通过SEM可以观察到浸泡24 h后,0B试样发生了严重腐蚀现象,大量晶界被腐蚀,呈现不完整的晶界网络,特别是三角晶界处,腐蚀最为严重(图6a1和a2)。添加B之后,试样的晶间腐蚀程度减轻,但表面仍有出现多点状的腐蚀坑,但相较0B试样有所缓解,特别是晶界腐蚀后为间断状态,表明B添加可显著改善晶界耐腐蚀性能(图6b1和b2)。B、Ce复合添加之后,表面腐蚀明显减弱,50B-20Ce晶界发生轻微腐蚀,晶界腐蚀凹槽不明显(图6c1和c2),而50B-50Ce试样的晶间腐蚀开裂程度最轻(图6d1和d2),晶界基本未被腐蚀,表现出超强的耐晶间腐蚀性能。由上可得,B、Ce微合金化提高了S31254不锈钢的耐晶间腐蚀性能,B、Ce协同更有助于提高S31254不锈钢的耐蚀性能,并且在本研究中当B与0.005%的Ce组合时,具有最佳的耐蚀性。

图6

图6

4种S31254不锈钢固溶后及在沸腾的硫酸-硫酸铁溶液中浸泡24 h后的形貌

Fig.6

Morphologies of four S31254 stainless steels after solid solution (a1-d1) and soaking in boiling sulfuric acid-ferric sulfate solution for 24 h (a2-d2):(a1, a2) 0B, (b1, b2) 50B, (c1, c2) 50B-20Ce, (d1, d2) 50B-50Ce

3 结论

(1) 在S31254不锈钢中加入B、Ce均可抑制时效过程中析出相析出,尤其B、Ce协同作用的效果最为明显,且B、Ce含量均达到0.005%时,S31254不锈钢晶内析出明显减少,晶界析出相数量也最少、尺寸最小,晶内与晶界析出效果最为显著。

(2) B、Ce微合金化的S31254不锈钢具有良好的耐点蚀性能和耐晶间腐蚀性能。B及B、Ce复合均可以提高材料的自腐蚀电位和点蚀电位,提高合金钝化膜稳定性,改善耐点蚀性能和耐晶间腐蚀性能。并且与单独添加B的实验钢相比,B、Ce协同作用对S31254不锈钢晶界与表面耐蚀性提升更为显著。

参考文献

Hot working characteristic of superaustenitic stainless steel 254SMO

[J].

Microstructural evolution and stability of coarse-grained S31254 super austenitic stainless steel during hot deformation

[J].

Characterization of the passive properties of 254SMO stainless steel in simulated desulfurized flue gas condensates by electrochemical analysis, XPS and ToF-SIMS

[J].

Elucidating the passivation kinetics and surface film chemistry of 254SMO stainless steel for chimney construction in simulated desulfurized flue gas condensates

[J].

Precipitation behavior and phase transformation of hyper duplex stainless steel UNS S32707 at nose temperature

[J].

Effects of Cr and Mo on precipitation behavior and associated intergranular corrosion susceptibility of superaustenitic stainless steel S32654

[J].

Effect of boron addition on the microstructure and mechanical properties of K4750 nickel-based superalloy

[J].The effect of boron addition at 0, 0.007 wt. % and 0.010 wt. % on the microstructure and mechanical properties of K4750 nickel-based superalloy was studied. The microstructure of the as-cast and heat-treated alloys was analyzed by SEM, EPMA, SIMS and TEM. Lamellar M5B3-type borides were observed in boron-containing as-cast alloys. After the full heat treatment, boron atoms released from the decomposition of M5B3 borides were segregated at grain boundaries, which inhibited the growth and agglomeration of M23C6 carbides. Therefore, the M23C6 carbides along grain boundaries were granular in boron-containing alloys, while those were continuous in boron-free alloys. The mechanical property analysis indicated that the addition of boron significantly improved the tensile ductility at room temperature and stress rupture properties at 750 ℃/430 MPa of K4750 alloy. The low tensile ductility at room temperature of 0B alloy was attributed to continuous M23C6 carbides leaded to stress concentration, which provided a favorable location for crack nucleation and propagation. The improvement of the stress rupture properties of boron-containing alloys was the result of the combination of boron segregation increased the cohesion of grain boundaries and granular M23C6 carbides suppressed the link-up and extension of micro-cracks.

Atomic-scale study on segregation behavior at austenite grain boundaries in boron- and molybdenum-added steels

[J].

Beneficial effect of B segregation on creep cavitation in a type 347 austenitic stainless steel

[J].

Corrosion resistance and passivation behavior of B-containing S31254 stainless steel in a low pH medium

[J].

Effect of boron on dissolution and repairing behavior of passive film on S31254 super-austenitic stainless steel immersed in H2SO4 solution

[J].

Effect of boron addition on the precipitation behavior of S31254

[J].

Impact of boron addition on the hot deformation behavior and microstructure evolution of S31254

[J].

Effects of Ce on inclusions and corrosion resistance of low-nickel austenite stainless steel

[J].

Effect of rare earth element Ce on corrosion resistance of 316L stainless steel

[J].

稀土Ce对316L不锈钢耐腐蚀性能的影响

[J].采用失重分析,扫描电镜 (SEM),能谱分析 (EDS),电化学阻抗谱 (EIS) 和动电位极化实验 (DP) 等方法研究稀土元素Ce对316L不锈钢在3.5% (质量分数) NaCl腐蚀环境中耐腐蚀性能的影响。结果表明,添加适量的稀土元素Ce可有效减小316L不锈钢在3.5%NaCl溶液中的重量损失,降低其腐蚀速率,减小腐蚀表面点蚀坑的尺寸与数量,提高316L不锈钢在3.5%NaCl溶液中的腐蚀电位,降低其腐蚀电流密度,增大容抗弧半径,提高耐蚀性能。因此,本文确定提高316L不锈钢在3.5%NaCl溶液中耐腐蚀性能的最佳稀土元素Ce含量为0.015%(质量分数),并进一步揭示了Ce改善316L不锈钢耐腐蚀性能的主要原因:Ce可有效降低有害元素S在晶界处偏聚,净化晶界;改善夹杂物的形貌,减小夹杂物的尺寸。

The influence of Ce micro-alloying on the precipitation of intermetallic sigma phase during solidification of super-austenitic stainless steels

[J].

Effect of cerium on the austenitic nucleation and growth of high-Mo austenitic stainless steel

[J].

Effect of Ce addition on secondary phase transformation and mechanical properties of 27Cr-7Ni hyper duplex stainless steels

[J].

The mechanism on the B addition to regulate phase precipitation and improve intergranular corrosion resistance in UNS S31254 superaustenitic stainless steels

[J].

Enhanced irradiation and corrosion resistance of 316LN stainless steel with high densities of dislocations and twins

[J].

Revealing the superior corrosion protection of the passive film on selective laser melted 316L SS in a phosphate-buffered saline solution

[J].