近年来,超疏水涂层在防结冰方面获得越来越多的应用,这类材料的低表面能和精细微纳结构可以减少水雾的附着,同时减缓了热传导过程,使冰在表面难以形成[5,6]。但在长时间极低温下超疏水涂层表面结冰仍不可避免,许多学者为解决这一问题进行了广泛深入的探索。研究[7,8]表明,光热超疏水涂层既能减少水雾附着结冰,又能通过光热升温主动除冰,安全、高效、便捷,能大幅度地提高防冰除冰效果。Hu等[9]在碘掺杂的聚合物基体上制备了具有被动防冰性能的SiO2/SiC涂层,具有优异的憎水性,接触角可达164°,在近红外光的照射下可以快速升温融化冰。Cheng等[10]以MNPs为热介质,与氨基改性的Fe3O4颗粒混合,再与二乙烯三胺交联制备得到多功能磁性杂化涂层,具有优异的超疏水性和润湿稳定性以及较长的结冰延迟性能和优异的热除冰性能。Jiang等[8]使用喷涂法制备了具有光热除冰和被动防冰性能的SiC/CNTs涂层,接触角和滚动角分别为161°和2°。在近红外光的照射下,涂层表面温度迅速升高,具有高效的除冰效果。

1 实验方法

实验用苯胺单体(AR,≥99.5%),过硫酸铵(AR,≥98%),盐酸(HCI,质量分数为37%),乙醇(95%),全氟癸基三乙氧基硅烷(96%),乙酸乙酯(AR,99.5%),氨水(AR,25-28%)试剂均购自中国阿拉丁试剂有限公司;有机硅树脂购自广州日气新材料有限公司,实验级马口铁购自苏州中路通实验仪器有限公司,尺寸为150 mm × 70 mm × 0.28 mm。

首先,将1.86 g苯胺溶于1 mol/L的盐酸水溶液中定容至100 mL,并放入冰箱降温至0℃。然后,将0.456 g过硫酸铵溶于1 mol/L的盐酸水溶液中定容至10 mL,并放入冰箱降温至0℃。接下来,在搅拌的条件下,将APS的溶液逐滴缓慢滴加到苯胺溶液中,反应体系在0℃下反应72 h。反应结束后,将所得溶液抽滤并用去离子水洗涤多次,最终得到聚苯胺粉末。然后,将1 g聚苯胺粉末加入到水-乙醇-氨水(50 mL,体积比为 = 1∶8∶1)的混合溶液中,在40℃下搅拌30 min形成分散液,随后将1 mL全氟癸基三乙氧基硅烷缓慢滴加到反应物溶液中,进行超疏水改性。之后,在40℃下搅拌反应24 h,将所得反应物溶液抽滤并用去离子水多次洗涤,最终烘干得到F-PANI粉末。最后,将1 g的有机硅树脂加入到10 g的乙酸乙酯中并搅拌10 min,然后将1 g的F-PANI粉末加入到上一步的混合溶液中,搅拌并用超声波分散均匀。在0.5 MPa的压力下,使用1.5 mm的喷嘴喷涂,并在室温下固化12 h,以获得光热超疏水涂层。

使用Regulus 8100 扫描电子显微镜(SEM)观察粉末样品和光热超疏水涂层的表面微观形貌。使用XFlash 6-30 X射线能谱仪(EDS)、Bruker Tensor II型Fourier红外光谱仪(FTIR)和Escalab 250Xi型X射线光电子能谱仪(XPS)来检测F-PANI粉末样品的成分。使用JY-82B接触角测量仪测试了涂层的接触角和滚动角。在砂纸磨损实验中,将表面涂有F-PANI光热超疏水涂层的马口铁固定在100 g砝码上,并将其与双面胶带粘合,如图1所示。然后将砝码和涂层一起放置在800目的砂纸上,并用水平力来回移动砝码,通过测量多次磨损循环后涂层的接触角和滚动角来评估涂层的耐磨损性能。落砂冲击实验则是将涂层固定在LS II型落砂耐磨试验仪(XM-LS)上,通过测量不同体积的落砂冲击后涂层的接触角和滚动角来评估涂层的耐磨损性能。为了验证F-PANI光热超疏水涂层的自清洁性能,参考前人研究[15~18],选用了墨水、可乐和牛奶3种黏度不同的测试液进行测试。将有机硅树脂涂层和F-PANI涂层分别浸泡在上述3种溶液中,观察浸没前后涂层表面液体的残留情况。用电化学工作站(DH7006)测量马口铁、有机硅树脂涂层(SR)和F-PANI涂层在3.5%(质量分数)NaCl溶液中浸泡24 h的电化学腐蚀情况。电化学测试采用三电极配置,工作电极为以上3种试样,暴露面积为1 cm × 1 cm,铂电极为对电极,AgCl电极为参比电极。电化学阻抗谱(EIS)测试的频率范围为105~10-2 Hz,交流振幅为10 mV。动电位极化曲线测试的扫描速率为1 mV/s,测试电路范围为开路电位± 300 mV。

图1

图1

制备氟改性聚苯胺粉末实验流程图

Fig.1

Experimental flow chart of the preparation of fluorine-modified polyaniline powders

使用了接触角测量仪(JY-82B Kruss DSA)、氙气灯和低温恒温槽相连的冷却平台来测试涂层的抗冰和除冰性能。为了评估涂层的抗结冰性能,使用氙气灯模拟不同强度的太阳光照射到涂层表面,在-25℃的条件下,观察并记录10 μL水滴完全结冰所需的时间。抗结冰性能主要通过延时结冰时间来评估。此外,为了研究光热超疏水涂层的光热转换能力,将有机硅树脂涂层和F-PANI涂层放在隔热性能良好的泡沫板上,并使用氙气灯模拟不同强度的光照射到涂层表面,通过红外相机记录涂层表面温度的变化情况。为了研究涂层在极寒条件下的光热效应,将涂层放置在冷却平台上,并调节冷却平台的温度和模拟太阳光照的强度,记录涂层表面的温度变化来评估其在极寒条件下的光热性能。最后,为了观察涂层的除霜和除冰过程,将涂层的温度调整至-15℃,并在涂层表面模拟太阳光照射的同时,通过空气冷凝水凝结和滴加水滴结冰来模拟除霜和除冰过程。所有的防冰和除霜、除冰实验都在相同的室温和湿度条件下进行。通过以上实验,可以评估涂层在不同条件下的抗冰性能、光热转换能力以及主动除霜和除冰能力,为进一步研发和应用具有优异性能的涂层提供科学依据。

2 结果与讨论

2.1 F-PANI粉末的表征

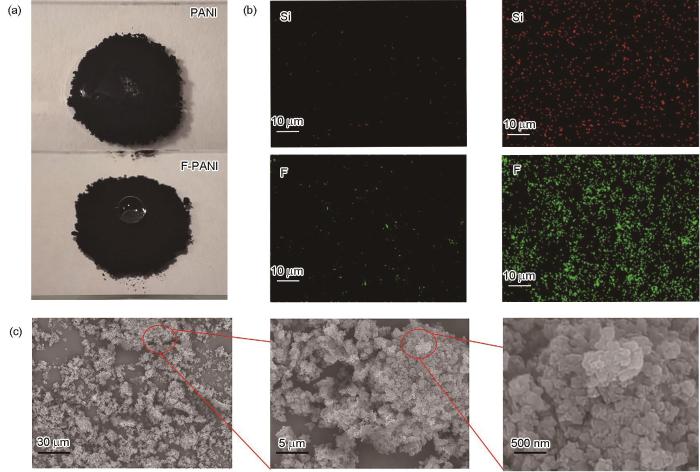

图2

图2

PANI和F-PANI粉末的润湿性对比形貌和EDS分析,及F-PANI粉末的SEM形貌

Fig.2

Comparisons of wettability (a) and EDS element mappings (b) of PANI and F-PANI powders, and SEM image of F-PANI powders (c)

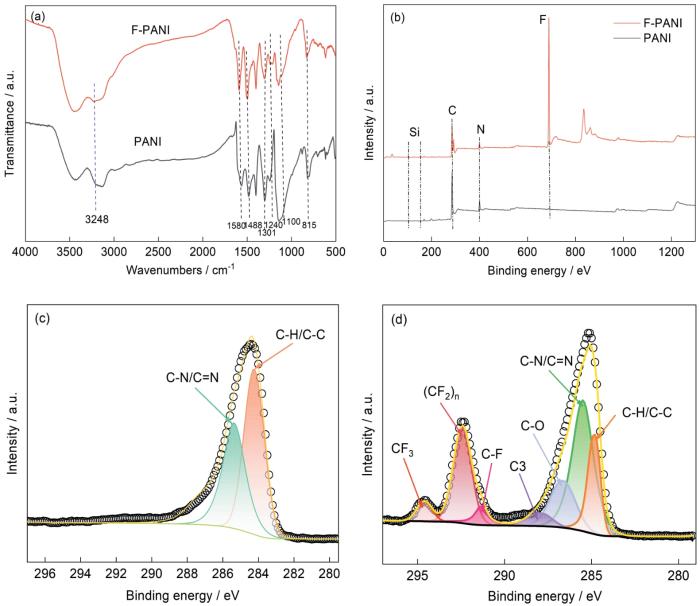

图3

图3

PANI和F-PANI粉末的FTIR谱和高分辨率XPS谱,及其C 1s XPS精细谱

Fig.3

FTIR (a) and XPS (b) spectra of PANI and F-PANI powders, and XPS fine spectra of C 1s of PANI (c) and F-PANI (d)

图3b为PANI和F-PANI的高分辨率XPS谱。由图可见,PANI中只有C和N,然而,在经过氟硅烷疏水改性后的F-PANI又观察到了Si和F,这表明氟化链段成功地接枝到了PANI上。对比图3c和d的 PANI和F-PANI的C 1s XPS谱可以观察,284.6、285.4 eV处,观察到了C-H/C-C、C-N/C=N [23]。在经过氟硅烷改性后,C 1s的XPS谱上出现了5个新的吸收峰,分别为C-O和C3(包含C-N+,C=N+,C=O)、C-F、(CF2)n和CF3,对应的结合能约为286.4、287.4、290.8、292.5、294.6 eV[24~26]。这些结果进一步证实了在PANI上成功地接枝了氟化链段。

2.2 光热超疏水涂层的表征

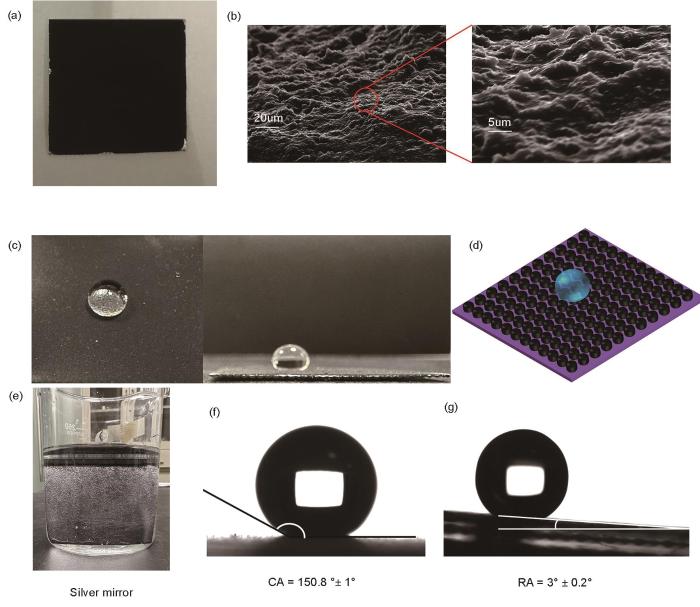

图4

图4

F-PANI涂层的宏观及微观形貌, 水滴在涂层表面的状态与Cassie润湿状态模型示意图,以及涂层在水中及其与水滴的接触角和滚动角照片

Fig.4

Optical photograph (a) and SEM images (b) of F-PANI coating, photographs of water droplet on the coating surface (c), schematic diagram of Cassie's model of the wetting state (d), digital photograph of the coating in water (e), and digital photographs of contact angle (f) and roll angle (g) of water droplet on the coating

2.3 涂层性能测试

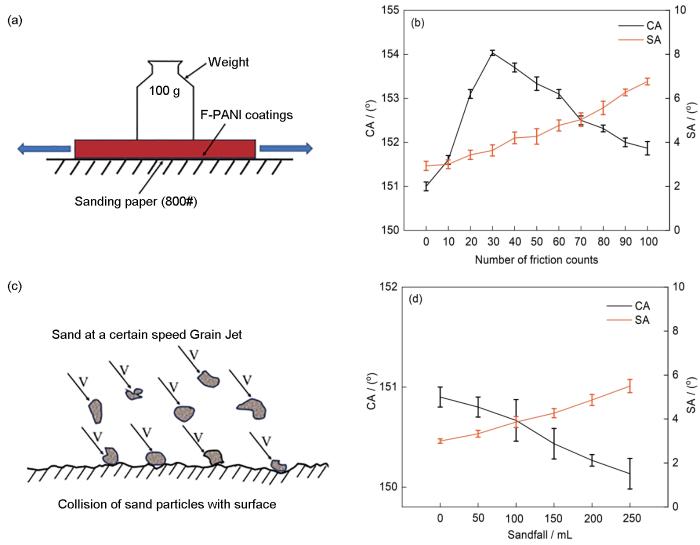

图5a为砂纸磨损实验的示意图,由图4b磨损实验中F-PANI涂层接触角和滚动角的变化情况可见,经过100次摩擦实验后,接触角由原来的150.8°增加到151.9°,滚动角由原来的3°增加到6.9°。在摩擦实验过程中,接触角增大的原因是800目砂纸本身就具有一定的微纳结构,在摩擦过程中优化了涂层表面的微纳结构。根据上述砂纸磨损实验结果,该涂层仍然具有超疏水性能[30]。图5c为落砂冲击实验的示意图,由图5d不同体积的砂子冲击涂层后的接触角和滚动角的变化情况可见,在经过250 mL的砂子冲击后,涂层的接触角为150.1°,滚动角为5.7°。因此,该涂层仍具有一定的超疏水性能。以上两个实验表明F-PANI涂层具有良好的力学性能。

图5

图5

F-PANI涂层砂纸磨损实验和落砂冲击实验示意图及其接触角和滚动角的变化曲线

Fig.5

Schematic diagrams (a,c)and variations of contact angle and sliding angle (b, d) for sandpaper abrasion experiment (a, b) and sand impact test (c, d) of F-PANI coating

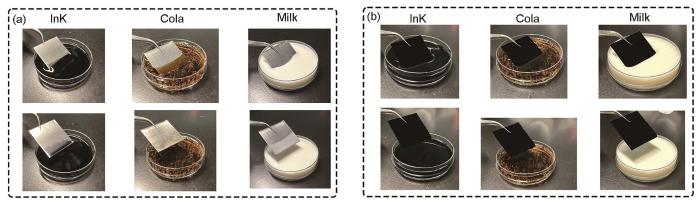

图6

图6

有机硅树脂涂层和F-PANI涂层在3种不同液体中的粘附行为

Fig.6

Adhesion performances of silicone resin coating (a) and F-PANI coating (b) in three different liquids

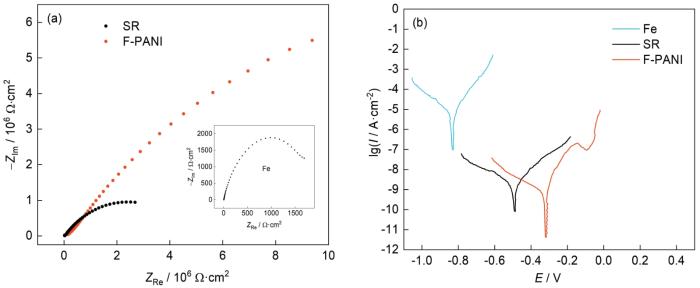

马口铁、有机硅树脂涂层和F-PANI涂层的EIS测试结果如图7a所示。由图可见,F-PANI涂层和有机硅树脂涂层的容抗弧半径远大于马口铁的容抗弧半径。通过使用DHMultiElec软件进行拟合,得到F-PANI涂层的容抗弧半径约为2.08 × 107 Ω·cm2,有机硅树脂涂层的容抗弧半径约为3.2 × 106 Ω·cm2,而马口铁的容抗弧半径约为1160 Ω·cm2。这表明F-PANI涂层的电阻约为有机硅树脂涂层的6倍,远远大于马口铁的电阻,表现出较好的防腐性能。马口铁、有机硅树脂涂层和F-PANI涂层的的动电位极化曲线测试结果如图7b所示。通过使用DHMultiElec软件对曲线进行拟合,得到马口铁的腐蚀电流约为2.067 × 10-5 A·cm-2,腐蚀电位约为-0.82 V;有机硅树脂涂层的腐蚀电流约为7.641 × 10-8 A·cm-2,腐蚀电位约为-0.48 V;F-PANI涂层的腐蚀电流约5.526 × 10-9 A·cm-2,腐蚀电位约为-0.34 V。腐蚀电位越趋于正值,腐蚀电流越小,腐蚀的趋势和速率就越低[31~33]。因此,与阻抗分析的结果一致,F-PANI涂层具有一定的防腐性能。

图7

图7

马口铁、有机硅树脂涂层和F-PANI涂层的电化学阻抗谱和动电位极化曲线图

Fig.7

Electrochemical impedance spectra (a) and dynamic potential polarization curves (b) of tinplate, organosilicone resin coating and F-PANI coating

2.4 有机硅树脂涂层和F-PANI涂层的被动防冰性能

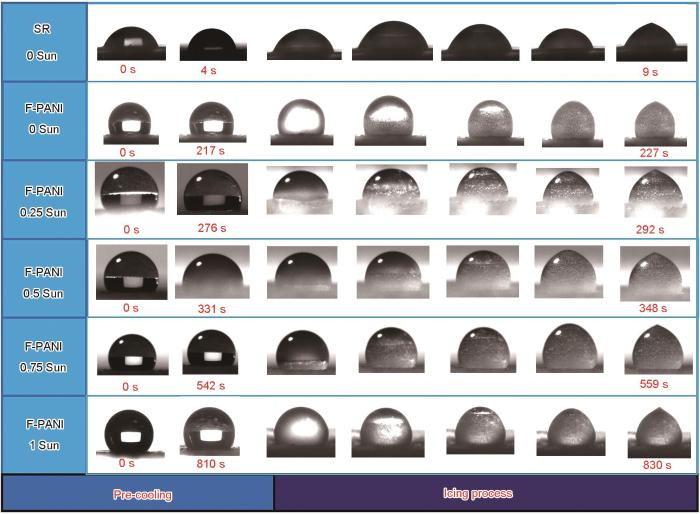

材料表面延时结冰的时间可以直观地说明材料表面的抗冰能力。图8显示了有机硅树脂涂层(SR)在无光照条件下和F-PANI涂层在不同模拟太阳光强度下的延时结冰过程。在有机硅树脂涂层上,10 µL的去离子水仅用时4 s就开始冻结,9 s后水滴已经变得完全不透明,此时水滴已经完全冻结。相比于有机硅树脂涂层,在无光照下的F-PANI涂层,直到217 s水滴才开始结冰,在大约227 s的时候完全冻结。这是因为适当的超疏水性可以极大地阻碍水滴的热交换过程,从而推迟结冰过程[34~36]。为了模拟极端天气条件下的太阳光照强度,本实验使用了4种不同的光强照射在涂层表面,并观察水滴在涂层表面延时结冰的过程。在0.25 Sun的强度下,水滴276 s开始结冰,在292 s完全冻结,顶部具有“疙瘩”特征[37]。同样地,在0.5 Sun的强度下,水滴331 s开始结冰,在348 s完全冻结;在0.75 Sun的强度下,水滴542 s开始结冰,在559 s完全冻结;在1个Sun强度下,水滴810 s开始结冰,在830 s后完全冻结。随着太阳光强度的增强,涂层表面水滴延时结冰的时间逐渐增加。主要原因是随着太阳光强度的增强,涂层表面的温度会逐渐升高。这改善了超疏水涂层在低温环境中疏水性能下降的缺点,从而增强了F-PANI涂层的被动防冰性能。

图8

图8

液滴在有机硅树脂涂层和F-PANI涂层上的延时结冰过程示意图

Fig.8

Schematic diagrams of the delayed icing processes of droplets on silicone resin coating and F-PANI coating

2.5 F-PANI涂层的光热性能和主动除霜、除冰性能

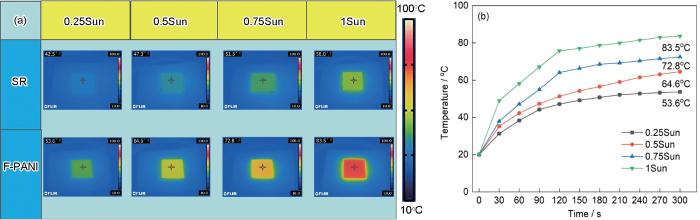

图9

图9

在不同光强下有机硅树脂涂层和F-PANI涂层表面最高温度的红外照片以及F-PANI涂层的升温曲线

Fig.9

Infrared photographs of the maximum surface temperatures of silicone resin coating and F-PANI coating at different light intensities (a), and warming curves of F-PANI coating (b)

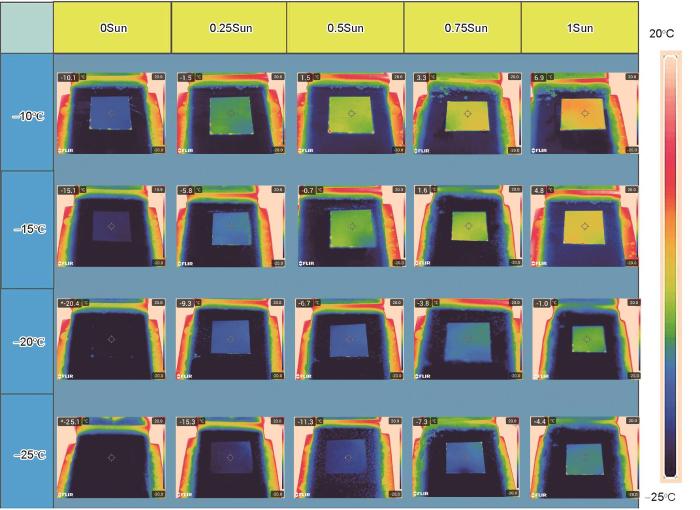

为了进一步评估F-PANI涂层在极寒条件下的光热转化能力,我们在不同温度梯度和光照强度下进行了测试,并记录了涂层表面在5 min内能达到的最高温度,结果如图10所示。从图中可以观察到,在(-15℃,0.75和1 Sun)以及(-10℃,0.5、0.75和1 Sun)的条件下,涂层表面的温度能够达到0℃以上。这些结果表明F-PANI涂层在寒冷条件下具有优异的光热转化能力,并具备一定的主动除冰潜力。

图10

图10

F-PANI涂层在不同温度和光照条件下5 min内最高温度红外照片

Fig.10

Infrared photographs of the maximum temperatures for F-PANI coating after 5 min exposure under the conditions of temperature and light intensity

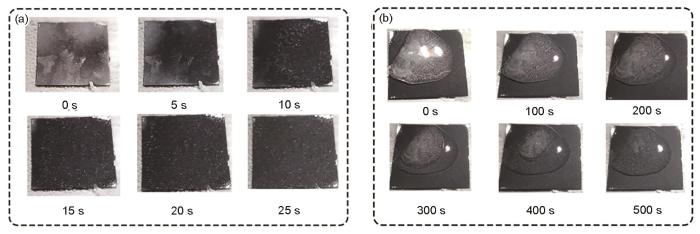

图11

图11

F-PANI涂层除霜和除冰实验过程中表面形貌变化

Fig.11

Surface topography changes of F-PANI coating during experimental processes of defrosting (a) and de-icing (b)

3 结论

本研究在酸性条件下合成了聚苯胺粉末,并通过FAS改性合成了具有低表面能的F-PANI粉末。F-PANI涂层的接触角为150.8°,滚动角为3°,表现出超疏水性能。经过砂纸磨损和落砂冲击测试,证明了涂层具备良好的机械性能。抗污性能测试和电化学测试表明,涂层具有一定的抗污能力和耐腐蚀性。与有机硅树脂相比,F-PANI涂层表现出优异的光热性能。尤为重要的是,该涂层在延时结冰、主动除霜和除冰方面显示出潜力。因此,本研究为光热抗冰涂层的实际应用提供了一定的参考价值 。

参考文献

Design of icephobic surfaces by lowering ice adhesion strength: a mini review

[J].

Improvement in electrical characteristics by surface modification of multi-wall carbon nanotube based buckypaper for de-icing application

[J].

Recent progress in preparation and anti-icing applications of superhydrophobic coatings

[J].

Electro-/photo-thermal promoted anti-icing materials: a new strategy combined with passive anti-icing and active De-icing

[J].

Research progress of superhydrophobic materials in the field of Anti-/De-icing and their preparation: a review

[J].

Recent progress in anti-icing and deicing applications of the photothermal conversion materials

[J].

Recent advancements in photothermal anti-icing/deicing materials

[J].

Superhydrophobic SiC/CNTs coatings with photothermal deicing and passive anti-icing properties

[J].

Superhydrophobic coatings on iodine doped substrate with photothermal deicing and passive anti-icing properties

[J].

Magnetic particle-based super-hydrophobic coatings with excellent anti-icing and thermoresponsive deicing performance

[J].

One-dimensional nanostructured polyaniline: syntheses, morphology controlling, formation mechanisms, new features, and applications

[J].

Preparations, properties, and applications of polyaniline and polyaniline thin films-a review

[J].

Polymer-based nanomaterials for noninvasive cancer photothermal therapy

[J].

Acid-doped polyaniline membranes for solar-driven interfacial evaporation

[J].

Fabrication of biocompatible super stable lubricant-immobilized slippery surfaces by grafting a polydimethylsiloxane brush: excellent boiling water resistance, hot liquid repellency and long-term slippery stability

[J].Slippery liquid-infused surfaces that imitate the microstructure of carnivorous Nepenthes have attracted widespread attention due to their excellent liquid and various organic solution repellency, associated with broad applications in various fields. However, the complicated preparation processes and poor oil lock ability of slippery liquid-infused surfaces severely restrict their practical application. Herein, lubricant-immobilized slippery surfaces (LISS) were fabricated by grafting polydimethylsiloxane onto ZnO nanorods under ultraviolet light, with residual non-bound silicone oil acting as a lubricant. In addition, the entire reaction is green, and the chemicals involved are inexpensive and environmentally friendly. Moreover, due to the strong intermolecular forces between the non-bound silicone oil and grafted polydimethylsiloxane, silicone oil is firmly locked to the zinc oxide surface, serving as a lubricant layer with a sliding angle of less than 3°. The LISS not only exhibited superior omniphobicity at room-temperature but also retained excellent sliding ability for high-temperature liquids such as hot water and oleic oil. When subjected to a boiling and high temperature test for 15 min, the liquids still slid on the surface with the tilt angles below 4° due to the presence of a uniform lubricant layer. In addition, under extreme operating conditions, such as high shear rate of up to 7000 rpm, long-term immersion for 400 h and strong acid/alkali, the LISS exhibited outstanding slippery stability. Furthermore, its properties of corrosion resistance, anti-icing and anti-fouling are of great significance for extending the practical application of LISS. Therefore, due to their excellent boiling water/hot liquid repellency and long-term slippery stability, the LISS may be promoted on a large scale and are a breakthrough for traditional slippery surface preparation.

Employing micro pyramidal holes and porous nanostructures for enhancing the durability of lubricant-infused surfaces in anti-icing

[J].

Lubricant-infused coating by double-layer ZnO on aluminium and its anti-corrosion performance

[J].

Design and fabrication of the lyophobic slippery surface and its application in anti-icing

[J].

Relation between structure and homogeneity of polyaniline blends by infrared and Raman spectroscopies

[J].

Characterization of polyaniline-polypyrrole composite coatings on low carbon steel: a XPS and infrared spectroscopy study

[J].

Infrared spectroscopic study of solid-state protonation and oxidation of polyaniline

[J].

Enhanced thermal conductivity of epoxy polymer alloys blend with fluorine-contained hybrid silicon dioxide

[J].

Thermal and XPS studies on polyaniline salts prepared by inverted emulsion polymerization

[J].

Environmental testing of hydrophobic fluorosilane-modified substrates

[J].

Superhydrophobic TiO2-polymer nanocomposite surface with UV-induced reversible wettability and self-cleaning properties

[J].

An abrasion-resistant, photothermal, superhydrophobic anti-icing coating prepared by polysiloxane-modified carbon nanotubes and fluorine-silicone resin

[J].

Research progress on preparation process of superhydrophobic polytetrafluoroethylene

[J].

超疏水聚四氟乙烯材料制备工艺的研究进展

[J].对用PTFE材料开发超疏水材料和薄膜,以及改性的思路进行了全面综述。首先,总结了超疏水PTFE块体与薄膜材料的加工工艺,并对各个方法的开发结果和特点进行了说明。此外,为进一步提升超疏水薄膜的特性,众多研究者还通过掺杂对薄膜进行改性,分别实现了增强其耐用性和与其他特性的融合。最后,对PTFE超疏水材料的发展和在防腐蚀领域的应用进行了展望。

Superhydrophobic materials used for anti-icing Theory, application, and development

[J].

An introduction to superhydrophobicity

[J].

Water-repellent and corrosion resistance properties of epoxy-resin-based slippery liquid-infused porous surface

[J].

Corrosion protection by organic coatings: electrochemical mechanism and novel methods of investigation

[J].

Corrosion electrochemical behavior of arc sprayed Al coatings

[J].

Influence of polyhydroxy hyperdispersant on anti-corrosion property of waterborne epoxy coatings

[J].

多羟基超分散剂对水性环氧涂层防腐性能的影响

[J].通过开路电位测量、电化学阻抗谱测试、动电位极化曲线测试、附着力测试等手段,研究了多羟基超分散剂对水性环氧清漆防腐性能的影响。结果表明,在3.5%NaCl溶液中,环氧清漆和含分散剂的环氧清漆的失效历程相同,可分为4个阶段:涂层快速吸水阶段、涂层腐蚀产物生成阶段、稳定腐蚀阶段和腐蚀产物扩散阶段。含分散剂的环氧清漆表现为较强的吸水性,多羟基超分散剂增加了涂层的饱和吸水率,加快了涂层的腐蚀失效。

Anti-icing potential of superhydrophobic coatings

[J].

A durable and photothermal superhydrophobic coating with entwinned CNTs-SiO2 hybrids for anti-icing applications

[J].

Preparation of PTFE/PDMS superhydrophobic coating and its anti-icing performance

[J].

A superhydrophobic coating harvesting mechanical robustness, passive anti-icing and active de-icing performances

[J].