1 实验方法

实验材料选用30 mm壁厚X70管线钢板,其化学成分(质量分数,%)为:C 0.05,Si 0.24,Mn 1.6,P 0.01,S 0.001,Cr 0.26,Ni 0.01,Cu 0.02,Mo 0.002,Nb 0.043,V 0.003,Ti 0.015,B 0.0002,Fe 余量。实验用电极规格为直径5 mm,高度8 mm圆柱体,除工作面以外用环氧树脂封装,测试面为圆形面积为0.2 cm2。实验溶液为0.2 mol/L Na2CO3溶液和0.2 mol/L Na2CO3 + 0.1 mol/L NaCl溶液,采用分析纯试剂和去离子水配制,实验室温约20℃,pH值11.3。

实验外加磁场由水平放置的配置Model P5 1307079直流恒电流源的电磁铁产生。工作电极置于电解槽中竖直放置,外加磁场方向与电极表面平行,磁感应强度为0.4 T。采用Gamry Interface 1010E 27029电化学工作站进行电化学测试,采用三电极体系。工作电极为X70管线钢,辅助电极(对电极)为铂电极,参比电极为饱和甘汞电极(SCE),除非特别说明,本文中电位均相对于SCE。电化学测试之前,工作电极用碳化硅砂纸逐级打磨至1500#,依次用酒精、丙酮清洗去除油脂,冷风吹干。每次动电位扫描阳极极化和恒电位极化测试之前先进行30 min开路电位(OCP)测试,待电位稳定后进行极化测试。动电位扫描阳极极化从OCP扫描到1.80 VSCE,扫描速率为1.667 mV/s;恒电位极化测试依据动电位扫描极化测试结果,无Cl-体系选择0.00、0.50 VSCE (位于钝化区)、0.80 VSCE(位于过渡区)、1.00 VSCE(位于准线性增长区)、1.20 VSCE(位于增速减缓区)、1.40 VSCE (位于电流密度平台区)6个电位;含Cl-体系选择0.20 VSCE (位于钝化区)、0.50 VSCE (位于过渡区)、1.00 VSCE (电流密度快速增长区) 3个电位。恒电位极化总时长1500 s,在0 T磁场下开始极化,随后每隔300 s分别进行外加或撤去0.4 T磁场操作。

2 结果与讨论

2.1 动电位扫描阳极极化曲线

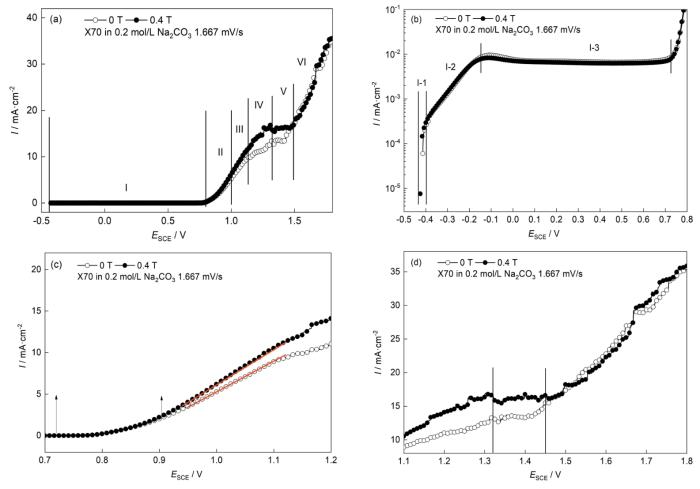

图1为有、无外加磁场时X70管线钢在0.2 mol/L Na2CO3溶液中的动电位扫描阳极极化曲线及各电位区间放大图。图1a显示曲线分6个区域,分别标记为I,II,III,IV,V,VI。I区:-0.43~0.80 VSCE,其电流密度随极化电位增大而基本保持不变,(∂I/∂E)I~0;II区:0.80~1.00 VSCE,其电流密度随极化电位增大而快速增大,(∂I/∂E)II > 0,(∂2I/∂E2)II > 0;III区:1.00 > 1.12 VSCE,其电流密度随极化电位增大而近似呈线性增大,(∂I/∂E)III为常数 > 0;IV区:1.12~1.32 VSCE,其电流密度随极化电位增大而缓慢增大,(∂I/∂E)IV > 0,(∂2I/∂E2)IV < 0;V区:1.32~1.50 VSCE,其电流密度随极化电位增大而大体保持不变,(∂I/∂E)V~0;VI区:1.50~1.80 VSCE,其电流密度随极化电位增大而近似呈线性增大,(∂I/∂E)VI为常数 > 0。

图1

图1

有无外加磁场时X70管线钢在0.2 mol/L Na2CO3溶液中的阳极极化曲线

Fig.1

Anodic polarization curves of X70 steel in 0.2 mol/L Na2CO3 solution with or without magnetic field: (a) OCP-1.80 VSCE, (b) OCP-0.80 VSCE, (c) 0.70 VSCE-1.20 VSCE, (d) 1.10 VSCE-1.80 VSCE

图1b为I区电流密度随电位变化的半对数线图,其可分为I-1、I-2、I-3区段。I-1段为极化起始阶段,电流密度在约30 mV范围内从约7.5 nA·cm-2增大到约280 nA·cm-2;I-2段为表观Tafel极化区,电流密度随电位近似呈线性增大;I-3段为微电流稳定区。选0.50 VSCE下电流密度为稳定值,由3组平行试验结果可得0 T时为6.76 ± 0.49 μA·cm-2,0.4 T时为6.69 ± 0.44 μA·cm-2,无显著差异,可见磁场对该电位区间内电流密度无明显影响。

图1c中0.70~0.90 VSCE电位区间磁场对极化电流密度作用开始显现,即0.4 T磁场下的电流密度大于0 T时。0.94~1.10 VSCE范围内电流密度随极化电位近似呈线性增大,可用

式中:E为极化电位(VSCE),I(E)为该电位下的电流密度(mA·cm-2),a为斜率,b为截距。3组平行实验数据线性拟合得到:0 T时a = 38.39 ± 2.33,b = -33.13 ± 2.39;0.4 T时a = 46.08 ± 5.09,b = -39.74 ± 4.61。0.4 T时斜率大于0 T时,可见磁场作用下升高电位对电流密度的增大作用更显著。

图1d结果表明,1.10~1.45 VSCE电位区间内0.4 T磁场作用下的电流密度明显高于0 T时,在1.32~1.45 VSCE电位区间出现一个电流密度平台区,有、无外加磁场的电流密度分别约为16和14 mA·cm-2;1.10~1.32 VSCE电位区间为线性增长区与平台区的过渡区;1.45~1.80 VSCE电位区间磁场的作用不明显。

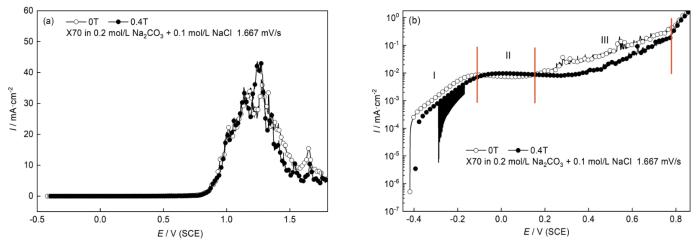

图2

图2

有无外加磁场时X70管线钢在0.2 mol/L Na2CO3 + 0.1 mol/L NaCl溶液中的阳极极化曲线

Fig.2

Anodic polarization curves of X70 steel in 0.2 mol/L Na2CO3 + 0.1 mol/L NaCl solution with or without magnetic field: (a) OCP-1.80 VSCE, (b) OCP-0.86 VSCE

2.2 恒电位极化测试

X70管线钢在0.2 mol/L Na2CO3溶液中恒电位极化测试结果如图3所示。图3a中0.00 VSCE极化下第一次外加0.4 T磁场电流密度无明显变化,撤去磁场后电流密度出现瞬时大幅下降;第二次外加磁场电流密度出现瞬时较宽间隔,撤去磁场出现瞬时电流密度峰值。图3b中0.50 VSCE极化下第一次外加0.4 T磁场电流密度出现瞬时峰值,撤去磁场后电流密度出现瞬时谷值;第二次外加磁场后电流密度出现瞬时峰值,撤去磁场后电流密度出现瞬时较宽间隔。图3c中0.80 VSCE极化下第一次外加0.4 T磁场电流密度由约0.62 mA·cm-2增长到约0.78 mA·cm-2,增幅约25%,撤去磁场后电流密度下降约20%;第二次外加和撤去磁场使电流密度变化情况与第一次相近。图3d中1.00 VSCE极化下第一次外加0.4 T磁场电流密度由约6.30 mA·cm-2增长到约7.50 mA·cm-2,增幅近20%,撤去磁场后电流密度下降约16%;第二次外加和撤去磁场使电流密度变化情况与第一次相近。图3e中1.20 VSCE极化下第一次外加0.4 T磁场电流密度上升,撤去磁场后下降;第二次外加和撤去磁场使电流密度变化情况与第一次相近。图3f中1.40 VSCE极化时第一次外加0.4 T磁场电流密度瞬时下降,撤去磁场后瞬时下降;第二次外加磁场后电流密度瞬时上升,撤去磁场后瞬时下降。以上结果表明,磁场对准线性增长区电流密度有增大作用,与动电位扫描阳极极化曲线结果一致。

图3

图3

有无外加磁场对X70管线钢在0.2 mol/L Na2CO3溶液中在不同VSCE下极化时电流密度的影响

Fig.3

Effect of applying or withdrawing magnetic field on current density of X70 steel in 0.2 mol/L Na2CO3 solution at 0.00 VSCE (a), 0.50 VSCE (b), 0.80 VSCE (c), 1.00 VSCE (d), 1.20 VSCE (e) and 1.40 VSCE (f)

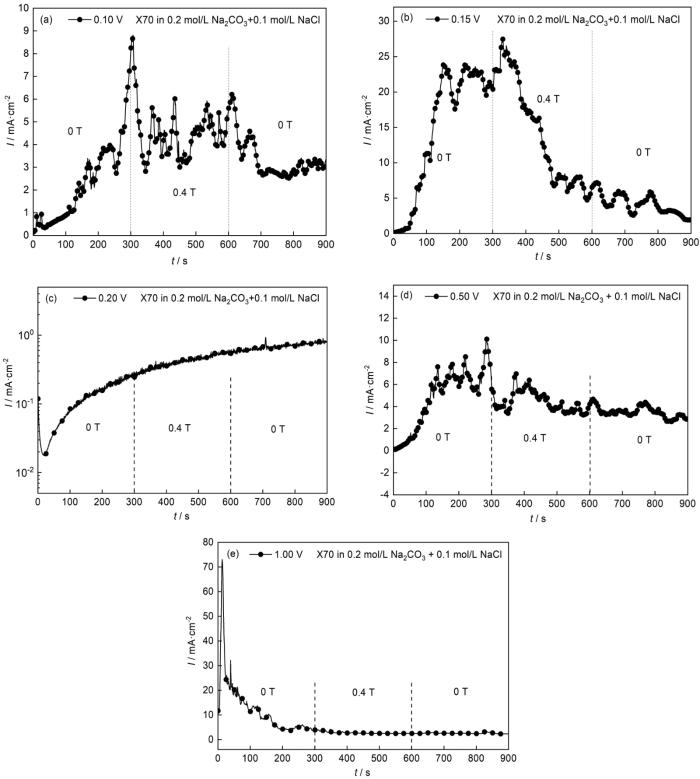

X70管线钢在0.2 mol/L Na2CO3 + 0.1 mol/L NaCl溶液中恒电位极化测试结果如图4所示。图4a表明,0.10 VSCE下极化时电流密度在前300 s内呈现增大趋势,在300s时外加0.4 T磁场后电流密度快速下降后处于较低数值,在600 s时撤去磁场后电流密度进一步降低而后逐渐趋稳。图4b结果表明,0.15 VSCE下极化后电流密度先增大之后在约150 s时达到第一个电流密度峰值之后趋向稳定,在300 s时外加磁场后电流密度先是出现短时间内的升高之后呈现降低的趋势,之后在600 s时撤去磁场时仍然表现出降低的趋势。图4c结果表明,0.20 VSCE下极化时电流密度随时间延长先降后升,加撤磁场对电流密度无显著影响。图4d结果表明,0.50 VSCE下极化时电流密度随时间延长增大后在较高值时有所波动,外加磁场后电流密度降低后基本稳定在较低值。图4e结果表明,1.00 VSCE下极化时电流密度在最初出现的一个暂态峰之后,电流密度逐步下降并趋向稳定。恒电位极化测试得到的磁场作用结果,与图2中极化曲线测试得到的结果有所不同,这与不同极化方式下达到某一电位时电极表面的不同状态有关。

图4

图4

外加或撤去磁场对X70管线钢在0.2 mol/L Na2CO3 + 0.1 mol/L NaCl溶液中在不同电位下极化时电流密度的影响

Fig.4

Effect of applying or withdrawing magnetic field on current density of X70 steel in 0.2 mol/L Na2CO3 + 0.1 mol/L NaCl solution at 0.10 VSCE (a), 0.15 VSCE (b), 0.20 VSCE (c), 0.50 VSCE (d) and 1.00 VSCE (e)

2.3 磁场对阳极反应的影响

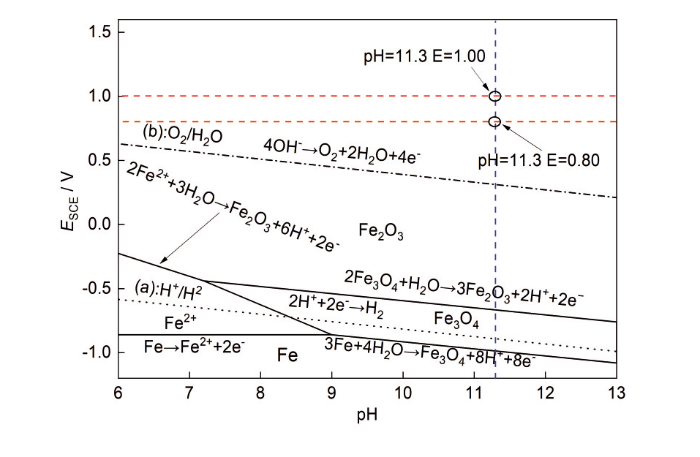

X70管线钢在0.2 mol/L Na2CO3溶液中从自腐蚀电位到约0.70 VSCE区间内为钝态,磁场对电流密度无显著影响。表明钝化膜比较稳定,磁场对钝化膜的溶解电流和阴极反应电流之和无显著影响。室温下Fe-H2O体系电位-pH图中,当pH = 11.3电位高于0.70 VSCE时发生析氧反应,如图5所示[14~17]。析氧反应缓慢且涉及四电子转移过程,机理较为复杂[18]。Man[19]等研究表明,析氧反应速率通常是受氧自由基生成或羟基氧自由基生成步骤的影响。O-O键的形成必须通过自旋守恒进行,以产生分子氧的顺磁性三重态,外加磁场可能通过促进氧自由基在O-O键形成过程中的平行排列,从而对电极反应起到加速作用[20]。磁场在0.80 VSCE和1.00 VSCE下极化时显著增大极化电流密度,极化过程中电极表面生成大量气泡,表明磁场能显著加速碳酸钠溶液中X70管线钢表面的析氧反应。极化曲线测试结果与恒电位极化测试结果有一定的对应性,虽然绝对数值会有差异。

图5

X70管线钢在0.2 mol/L Na2CO3 + 0.1 mol/L NaCl溶液中,由于Cl-的强侵蚀性阳极溶解加速,阳极极化曲线中0.20~0.70 VSCE区间的电流密度较高。在0.10和0.15 VSCE恒电位极化一定时间后外加磁场导致电流密度出现下降趋势,表明磁场有一定的抑制阳极过程的作用,分析原因可能是来源于磁场对电极表面界面反应物质传输层中活性物质的迁移速率有影响,比如影响侵蚀性离子或者金属离子的迁移速率;同时也发现加撤磁场的作用不具有可逆性,表明电极-溶液界面在极化过程中会发生明显的变化而导致磁场发生作用的对象发生变化。在高电位比如1.00 VSCE下极化时X70管线钢表面同时发生快速溶解反应和析氧反应,这种条件下磁场对阳极电流密度的影响不明显,推断是由于电极表面的活性溶解在阳极电流密度中占比较高。溶液中含有Cl-时,阳极极化曲线测试和恒电位极化测试得到的磁场对阳极电流密度的影响结果会表现出不同的趋势,这与不同极化方式极化到同一电位时出现差别较大的电极表面状态有关,从而导致电极反应机理与随之而变化的磁场影响不同。

3 结论

(1) 外加磁场加速X70管线钢在碳酸钠溶液中高电位下的析氧反应,而对钝化膜稳定状态没有显著影响。

(2) 在含Cl-的碳酸钠溶液中,在动电位扫描得到的X70钢阳极极化曲线的钝化区中进行恒电位极化,当极化电位接近过钝化过渡区时外加磁场表现出抑制阳极溶解的效应;在高电位下快速阳极溶解反应和析氧反应同时发生时,磁场对电流密度无显著影响。

(3) 溶液中不含侵蚀性离子时,采用极化曲线测试与恒电位极化测试得到的磁场的作用对应性相对较好。当溶液中含有Cl-时,极化曲线测试结果与恒电位极化测试结果会出现显著的偏差,这与不同极化方式导致的不同电极表面状态有关。

参考文献

New progress in China's oil and gas pipeline construction in 2022

[J].

2022年中国油气管道建设新进展

[J].

Research progress and prospect of stress corrosion cracking of pipeline steel in soil environments

[J].

管线钢土壤应力腐蚀开裂研究进展及展望

[J].综述了埋地管线钢在管道外部环境中开裂机理的研究进展,总结了材料因素 (合金元素、显微组织、夹杂物) 、环境因素 (外加电位、pH、温度、侵蚀性离子) 和应力因素 (残余应力、载荷类型、应变速率) 对管线钢SCC行为和机理的影响规律,梳理了两类典型pH SCC机理的形成过程,讨论了经典裂纹扩展速率预测模型的先进性和局限性,最后针对研究存在的不足展望了埋地管线钢SCC未来的研究方向。

Effect of magnetic field on corrosion behavior of X52 pipeline steel in NaCl solution

[J].

磁场对NaCl溶液中X52管线钢腐蚀行为的影响

[J].

Effect of residual magnetic field in magnetic flux leakage detection on DC stray current corrosion behavior of oil and gas pipeline

[J].

漏磁检测剩余磁场对油气管道直流杂散电流腐蚀行为的影响

[J].

Effects of direct current interference on corrosion behavior of X65 steel

[J].

直流杂散电流对X65钢腐蚀行为的影响

[J].

Study of interference parameters variation regularity and corrosion behavior of X80 steel in Guangdong soil under high voltage direct current interference

[J].High voltage direct current transmission (HVDC) systems develop fast in China recently. The ground electrodes of HVDC systems can inject/absorb large amount of DC current into/from soil, introducing DC interference to nearby pipelines. Then the pipe-to-soil potential shifts positively and high corrosion risk may appear. In this work, indoor HVDC simulation experiments were designed and carried out based on the field test results. Under high voltages, the variation regularity of DCdensity and the corrosion behavior of X80 steel in Guangdong soil were studied. The result showed that under 50, 100, 200 and 300 V DC voltages, the DC density of the coupons had the same trend and could be divided into 3 stages. Firstly, the DC density climbed to peak sharply in several seconds. Then, the DC density decreased gradually to steady value in hundreds of seconds. Lastly, the DC density stayed at that level for the rest of time. The local environment was monitored. The results indicated the variation of the DC density was mainly related to the local soil temperature increment, water content decrement and the substantially growth of the soil spread resistance. After the interference, the corrosion rates were measured to be 5.56, 7.85, 10.63 and 7.78 μm/h, respectively. The variation regularity of the corrosion rates was same with the steady values of DC density, but different from the peak values. Furthermore, 3 methods of calculating corrosion rates were studied. The theoretical corrosion rates calculated by integration of DC density curve had the smallest errors compared with the measured values. The method of using steady DC density had bigger errors and using peak DC density led to the biggest errors. Based on the results, the method of predicting HVDC corrosion rate was proposed.

高压直流干扰下X80钢在广东土壤中的干扰参数变化规律及腐蚀行为研究

[J].通过室内模拟实验考察了大幅高压直流干扰电压下,X80钢在广东土壤中的干扰电流密度变化规律及腐蚀行为。结果表明,在50~300 V直流干扰电压下,电流密度随时间的变化呈现典型的3阶段特征:首先,在几秒内急剧上升到较高水平的峰值;然后,在几百秒内下降到较低水平的稳定值;最后,较长时间内维持在稳定值水平。结合干扰过程中试样附近土壤温度、含水率及电阻的测试分析表明,电流密度变化主要是由大幅干扰电压造成短时间内试片周围土壤温度升高,含水率降低,局部电阻率大幅增加所致。同时实验获得直流干扰电压分别为50、100、200及300 V时,1 h干扰实验中X80钢腐蚀速率分别为5.56、7.85、10.63及7.78 μm/h;腐蚀速率随直流干扰电压的升高呈现先增大后减小的趋势,该趋势不同于电流密度峰值随直流干扰电压的变化规律,但与电流密度稳定值的变化规律相似。此外,分析了高压直流干扰下试样腐蚀速率与使用3种形式电流密度计算得到的理论腐蚀速率之间的相关性。结果表明,利用干扰过程中电流密度曲线积分计算得出的理论腐蚀速率误差最小;利用电流密度稳定值计算得到的腐蚀速率误差次之;利用电流密度峰值计算得出的理论腐蚀速率误差最大,可达到实测腐蚀速率的若干倍。据此提出了实际高压直流干扰下参数监测与腐蚀速率的预测方法。

Causes of high amplitude of pipe-to-soil potential under HVDC interference and influencing factors

[J].

高压直流干扰大幅值管地电位产生原因及影响因素分析

[J].

Effect of magnetic field on corrosion of X80 pipeline steel in meadow soil at Shenyang area

[J].

磁场对X80管线钢在沈阳草甸土中腐蚀行为的影响

[J].采用失重法并结合XRD,SEM和EDS等手段,研究了磁场对X80管线钢在沈阳草甸土中腐蚀行为的影响规律。结果表明:磁场的存在促进了X80管线钢在沈阳土壤中的腐蚀;与无磁场相比,外加磁场下X80钢电极表面腐蚀产物出现了疏松多孔型的FeO(OH),导致产物膜保护性减弱;随着磁场强度的增大,腐蚀产物中Fe<sub>3</sub>O<sub>4</sub>含量降低,FeO(OH) 含量增多,产物膜保护性逐渐减弱,X80钢腐蚀速率逐渐增加,但增大的幅度逐渐减小。磁场强度增大到一定程度会抑制完整产物膜的形成,当磁场达到20 mT时,X80钢年平均腐蚀速率达到73.799 μm/a,产物膜完整性差,出现了明显的裂纹,腐蚀现象最为严重,这是由于磁场能够使单个氧化物晶粒沿择优取向生长的缘故。

Study of corrosion behavior of magnetic field on the steel of oil sewage pipeline

[J].

磁场对石油污水管线钢的腐蚀行为研究

[J].

Review of stress corrosion cracking of pipeline steels in “low” and “high” pH solutions

[J].

Effects of an applied magnetic field on the dissolution and passivation of iron in sulphuric acid

[J].

Magnetic field effects on anodic polarisation behaviour of iron in neutral aqueous solutions

[J].

Effects of a magnetic field on the anodic dissolution, passivation and transpassivation behaviour of iron in weakly alkaline solutions with or without halides

[J].

A review on Pourbaix diagrams and their applications in metal corrosion and its prevention

[J].

布拜图及其在金属腐蚀与防护中的应用(综论)

[J].

Effects of sulfate ions on anodic dissolution and passivity of iron in slightly alkaline solutions

[J].

The effects of hydrogen on anodic dissolution and passivation of iron in alkaline solutions

[J].

Universality in oxygen evolution electrocatalysis on oxide surfaces

[J].