Feng等[16]通过在AZ91镁合金表面进行稀硫酸刻蚀加硝酸银处理,并用十二硫醇改性后制备了具有珊瑚状结构的超疏水表面,其对于水的静态接触角为154°,滚动角为5°,经过测试其耐腐蚀性提高。Liang等[17]利用CuCl2溶液刻蚀结合硬脂酸修饰的方法在镁合金基体上制备了具有花瓣状微观结构的超疏水表面,其自腐蚀电位正移了0.48 V,容抗弧直径几乎是未处理合金的两倍。Liu等[18]在AZ91D镁合金基底上利用镀镍工艺结合硬脂酸修饰制备了椰菜花状的超疏水表面,其静态接触角达到了160.1°,滚动角为1.8°,且在3.5% (质量分数) NaCl溶液中具有良好的耐腐蚀性。Gao等[19]利用H2O2溶液中的水热反应,并用氟硅烷修饰的方法在镁合金基体上制备了超疏水表面,其表面结构由大量球体组成,并随机堆叠形成了特殊微纳米复合结构,其静态接触角为164°,表现出优异的疏水性,且在电化学测试中表现出良好的耐蚀性。

本文采用操作简便的化学刻蚀法,旨在利用稀硝酸刻蚀在AZ31B镁合金表面构建具有一定粗糙度的微纳米复合结构,结合PFDTES进行低表面能修饰来制备超双疏表面,并通过对基体和制备的超双疏试样进行电化学测试探究其耐蚀性能。

1 实验方法

实验用AZ31B镁合金主要成分(质量分数,%)为Al 3.1、Zn 0.9、Mn 0.32、Mg余量。实验用化学试剂包括全(十七)氟癸基三乙氧基硅烷(PFDTES,C16H19F17O3Si),硝酸(分析纯),乙醇(99%);丙酮、乙二醇、NaCl为分析级。

首先,依次用400#、800#、1200#、2000#的砂纸对AZ31B镁合金进行砂磨,然后用丙酮、乙醇和超纯水依次进行超声10、10和5 min,防止去除表面氧化膜后的镁合金发生氧化,同时去除镁合金表面的油脂和杂质。

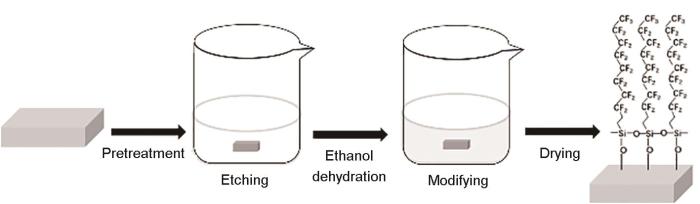

将预处理后的镁合金浸泡在一定浓度的稀硝酸(V(HNO3)∶V(H2O) = 1∶20)中刻蚀不同时间,迅速取出酸刻蚀后的镁合金并置于超纯水中去除表面残留的酸;然后,将其置于梯度浓度的乙醇中进行脱水处理;最后,将处理后的镁合金置于1.0% (质量分数)PFDTES的乙醇溶液中1 h进行低表面能修饰,再将其置于烘箱中在60℃下固化干燥1 h。利用化学刻蚀法在镁合金基体上制备超双疏表面的工艺流程如图1所示。

图1

图1

镁合金超双疏表面的制备流程示意图

Fig.1

Schematic diagram of preparation process of superamphiphobic surface on Mg-alloy

采用接触角测量仪测量不同表面张力的液体(水和乙二醇)在镁合金试样表面的接触角,测试过程中,试样的接触角值取镁合金表面上位于5个不同位置的接触角的平均值。采用扫描电子显微镜 (SEM,Gemini300)对试样表面的微观形貌进行测试表征。通过X射线衍射仪(XRD,D8 ADVANCE,采用Cu Kα靶材,管电压40 kV,电流30 mA)和能量色散X射线光谱(EDS)表征试样的物相组成,利用X射线光电子能谱仪(XPS, Thermo Scientific K-Alpha)对试样表面成分状态进行测量分析。

使用CHI660E电化学工作站对试样进行动电位极化曲线和电化学阻抗谱(EIS)测量,来探究超双疏试样的耐腐蚀性能。所有电化学测量均是在3.5%NaCl溶液中进行的,测试过程采用标准三电极体系,其中将试样制成暴露面积为1 cm2的工作电极,Pt片和饱和甘汞电极(SCE)分别作为对电极和参比电极。在测定动电位极化曲线时,扫描速率参数设定为2 mV/s。在开路电位下进行EIS测试,扫描频率范围设为105~10-2 Hz,正弦波振幅值参数为10 mV,利用ZSimpwin软件对EIS进行拟合分析。

2 结果与讨论

2.1 润湿性分析

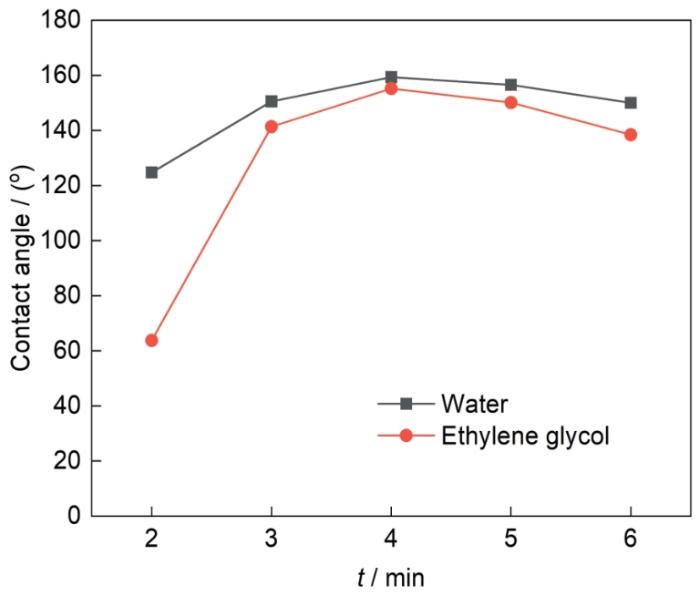

本文研究了硝酸刻蚀时间对镁合金表面超双疏效果的影响,如图2所示。结果表明刻蚀4 min时,水在样品表面的静态接触角达到最大值159.3°和低滚动角2°,甚至具有较低表面张力的乙二醇(γ = 47.7 mN·m-1,20℃)也具有最大接触角155.2°和低滚动角8°。

图2

通过测量水和乙二醇在镁合金表面上的接触角探究了不同处理方法对试样润湿性的影响,如表1所示。可以看到,水在未经处理的镁合金表面的接触角为75.8°,乙二醇的接触角为63.5°,这是由于镁合金本身属于亲水/油材料[20],其表面粗糙度小且表面能较大,水/乙二醇可以浸润其表面。而经过简单的400#、800#、1200#和2000#的砂纸依次打磨后的镁合金试样,水的接触角降至34.1°,乙二醇的接触角也大幅降低至13.2°。继续对砂磨后的试样进行刻蚀会观察到其表面水/乙二醇的接触角都在继续降低,其中水的接触角降为13.6°,而乙二醇由于是油类物质,具有较低的表面张力,其在刻蚀后的试样表面上完全铺展开,接触角约为0°。这种现象是由于表面粗糙度增加,会导致原本亲水的表面更加亲水[21]。对不同试样表面进行低表面能修饰后,对未经处理的镁合金裸样进行砂纸打磨后立即进行低表面能修饰,水的接触角为128.8°,乙二醇的接触角为113.6°,均达到了疏液状态;而对砂纸打磨后的试样继续进行刻蚀后再对其进行低表面能修饰,其水接触角达到了159.3°,表面张力较低的乙二醇也达到了155.2°,液滴在试样表面都呈现出球状,改变了原本的润湿状态,达到了超双疏的要求。以上结果证明了粗糙度和低表面能修饰剂对于表面润湿性都有着直接的影响,粗糙度的增大会导致原本亲水的表面更加亲水,疏水的表面更加疏水[21,22],而低表面能修饰剂降低表面能的作用会使超亲水材料表面直接转变为超疏水表面[23]。

表1 不同液体在不同加工条件下试样接触角的变化

Table 1

Liquid | Surface tension (20oC) mN·m-1 | Bare | Sanding | Sanding + modifying | Sanding +etching | Sanding + etching + modifying |

|---|---|---|---|---|---|---|

| Water | 72.8° | 75.8° | 34.1° | 128.8° | 13.6° | 159.3° |

| Ethylene glycol | 47.7° | 63.5° | 13.2° | 113.6° | 0° | 155.2° |

2.2 表面微观形貌分析

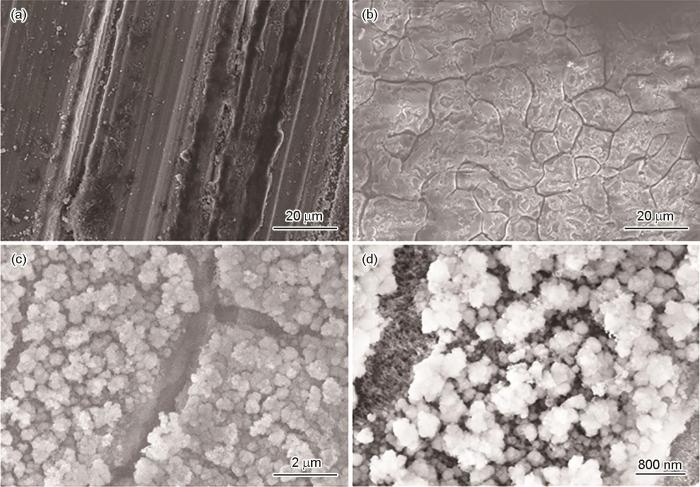

图3为基体和超双疏试样表面的SEM图。由图3a可见,未经处理的镁合金表面有较为明显的划痕及杂质,经过预处理并刻蚀修饰后,镁合金表面发生龟裂现象(图3b),对其进行放大(图3c和d)可以观察到其表面由众多规则的纳米级球状及其相互堆叠而成的特殊微纳米复合结构组成,在镁合金表面上形成类似于荷叶表面微观结构的分层粗糙结构[15]。镁合金基体主要包含两种相,即富镁的α相和富铝的β相[24]。此外,由Mn、Zn、Al和其他微量元素组成的其他相和杂质也存在于AZ31B镁合金的内部。Galicia等[25]使用局部电化学阻抗谱研究了镁合金表面的阻抗分布,观察到α相的电极电位低于β相。这表明,α相的耐腐蚀性较差,在外界条件的作用下会导致α相优先溶解,相比之下,具有较高电极电位的β相的溶解速率比α相慢,并且β相保留在表面上,随着加工时间的增加和镁合金表面某些部分的α相溶解的进行,一些突起将作为残余物分离,并被电解液带走。由于镁合金成分不均匀性导致其在刻蚀过程中溶解速率不同,溶解程度也不同,致使其表面出现不同的形貌,在刻蚀一定时间后其表面形成的特殊粗糙结构对于制备超双疏表面有着重要作用。

图3

图3

试样基体及超双疏试样表面形貌

Fig.3

Surface morphologies of bare sample (a) and superamphiphobic sample (b-d)

2.3 试样表面结构和化学成分分析

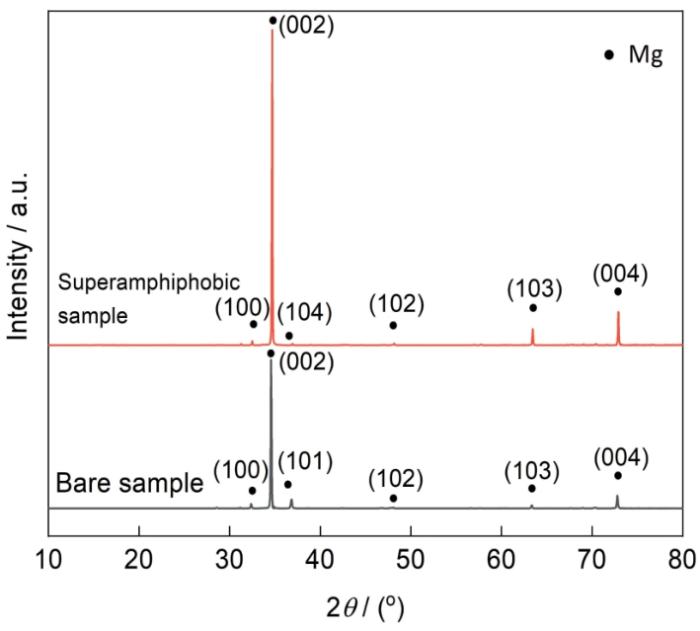

图4

图4

基体及超双疏试样的XRD谱

Fig.4

XRD pattern of bare sample and the superamphiphobic sample

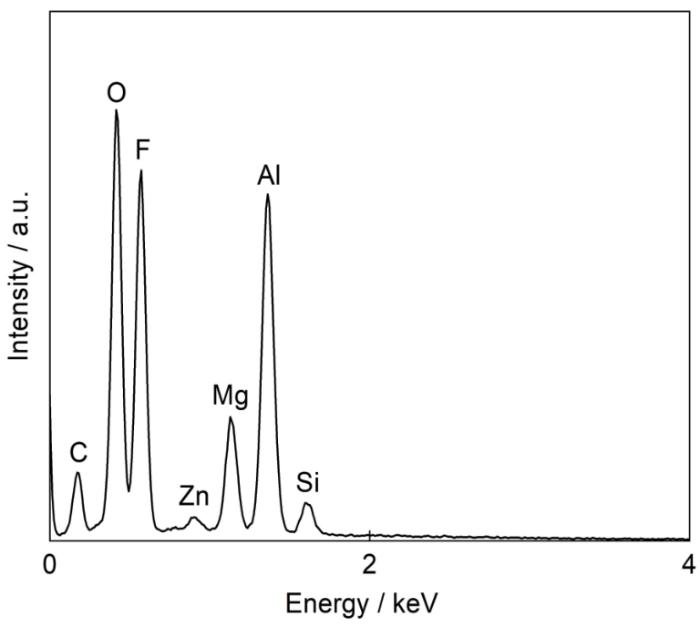

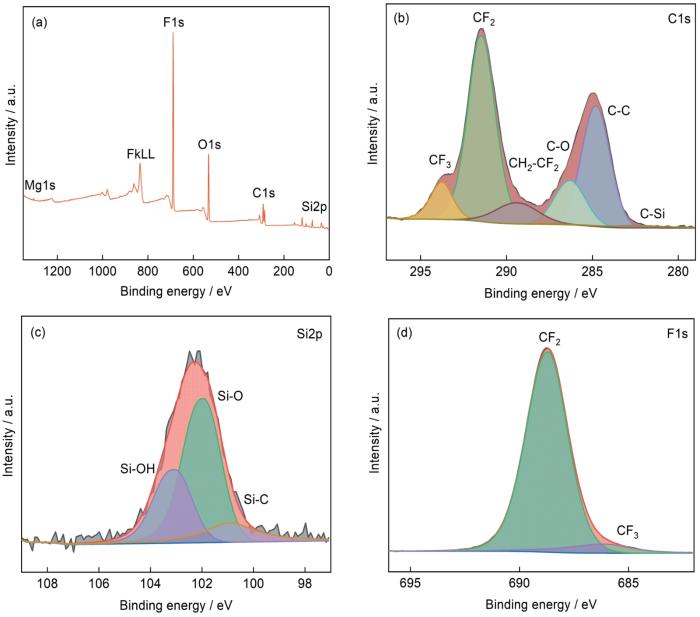

为了探究超双疏表面的化学成分及其化学状态,对试样进行了EDS和XPS测试。从图5的EDS结果可以看出,制备的超双疏试样表面存在F的峰,可以初步证明氟硅烷成功修饰了镁合金表面。为了更进一步探究超双疏表面化学成分,对样品进行了XPS测试,结果如图6所示。由图6a的全谱中可以看出,超双疏试样表面含F、O、C、Si、Mg元素。从图6b C 1s窄谱可以观察到C-F3(293.7eV)、C-F2(291.5 eV)、CH2-CF2(289.8 eV)、C-O(286.6 eV)、C-C(284.8 eV)和C-Si(281.8 eV)6种成分[26]。另外,从图6c Si 2p窄谱可以看出,在结合能为102.6、101.9和100.9 eV出现了分别对应Si-OH键、Si-O键及Si-C键的能级峰[26],这源于PFDTES水解后形成Si-OH,并在样品表面发生缩合反应[27],表明氟硅烷的低表面能基团成功接枝到样品表面,达到了降低样品表面能的目的,结合图6d可以证明氟硅烷成功修饰了试样表面。

图 5

图6

图6

超双疏试样的XPS谱

Fig.6

XPS spectra of the superamphiphobic sample: (a) survey, (b) C 1s, (c) Si 2p, (d) F 1s

2.4 耐蚀性分析

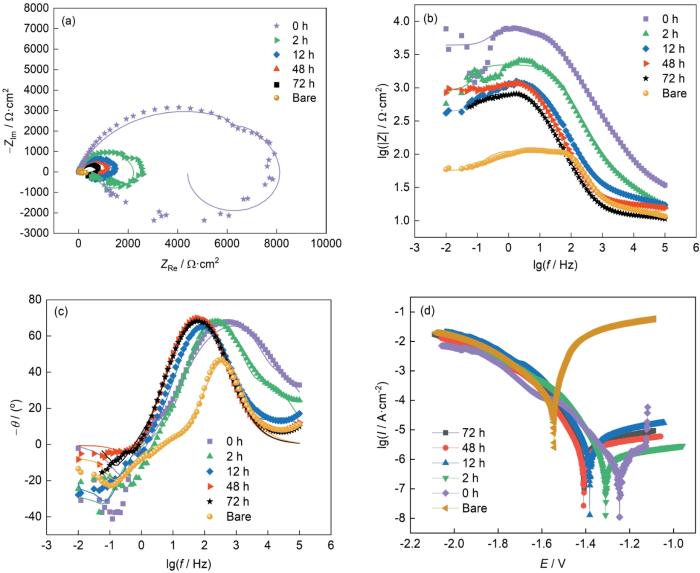

通过对不同试样在3.5%NaCl溶液中进行电化学测试,研究样品在模拟海水环境下的耐蚀性,结果如图7所示。

图 7

图 7

基体和超双疏试样在3.5%NaCl 溶液中的电化学测试

Fig.7

Electrochemical test of the bare sample and superamphiphobic sample in 3.5%NaCl solution: (a) Nyquist plot, (b) Bode impedance modules plot, (c) Bode phase angles plot, (d) potentiodynamic polarization curve

图7a为镁基体和在3.5%NaCl溶液中浸泡不同时间的超双疏试样的Nyquist图。从该图谱可以看出,在浸泡前期由一个高频容抗,一个中频容抗和一个低频感抗组成,而在浸泡后期,则由一个高频容抗和一个低频感抗组成。其中高频区容抗弧是试样表面膜/超双疏膜层的防护作用,容抗弧半径越大,电荷转移越困难,代表试样耐蚀性越好,中频区的容抗弧是试样浸泡前期生成的腐蚀产物层的作用,且随着浸泡时间的延长,其表面的腐蚀产物膜层越来越疏松,失去了腐蚀防护能力。而低频区的感抗弧则对应于点蚀的出现[28]。无论是裸样表面疏松的氧化膜还是超双疏试样表面的超双疏膜都具有一定的防护能力,只是未经处理的镁合金基体表面的氧化膜是疏松结构,极易在3.5%NaCl溶液中被破坏,产生点蚀,失去防腐蚀能力。相较于镁合金基体,超双疏试样由于前述提到的独特的润湿性能,其表面与3.5%NaCl溶液形成空气层,阻碍腐蚀介质与基体的接触[29],大大降低了与3.5%NaCl溶液中腐蚀性Cl-的接触,减缓了腐蚀速率,增大了电荷转移过程中的阻力,提高了试样的耐蚀性。

图7b为试样在3.5%NaCl溶液中的Bode阻抗模图。在浸泡2 h后阻抗值就大幅下降,而且在7a中可以看出所有浸泡时间都存在感抗,且低频Bode图都是乱点,表明该样品的耐蚀性较差,阻抗测试过程中已经发生了明显的腐蚀。但比较而言,在低频区超双疏试样的|Z|值远大于未经处理的镁合金裸样,随着浸泡时间的增加,阻抗模值一直减小,但即使浸泡72 h的超双疏试样的|Z|值也依旧比裸样更高,证明超双疏试样在3.5%NaCl溶液中具有良好的耐蚀性。从图7c的相位角与频率关系的Bode图来看,超双疏试样相较于裸样在高频区域具有更明显的保护效果,基体在测试范围内呈现两个时间常数,对应于高频(102~103 Hz)表层疏松氧化膜的保护作用和低频(10-2~10-1 Hz)下点蚀的产生,其中低频段也对应了图7a中的感抗弧。

图8

图8

基体和浸泡不同时间的超双疏试样的等效电路

Fig.8

Equivalent circuit: (a) bare sample and superamphiphobic sample immersed for above 12 h, (b) superamphiphobic sample immersed for 0-12 h

表2 电化学拟合参数

Table 2

| Sample | Rs Ω·cm2 | CPE Y0 (S·sec n) n | Rct Ω·cm2 | Rf Ω·cm2 | Cdl F·cm-2 | RL Ω·cm2 | L H·cm2 | |

|---|---|---|---|---|---|---|---|---|

| bare | 13.91 | 2.049 × 10-5 | 0.9240 | 41.93 | / | / | 57.01 | 40.93 |

| 0 h | 18.71 | 3.239 × 10-6 | 0.7297 | 8580 | 175.0 | 1.148 × 10-7 | 8794 | 6517 |

| 2 h | 14.37 | 3.506 × 10-6 | 0.8240 | 2172 | 59.51 | 1.298 × 10-6 | 909.4 | 4942 |

| 12 h | 11.68 | 6.741 × 10-6 | 0.8928 | 1331 | 21.13 | 2.638 × 10-6 | 885.3 | 8950 |

| 48 h | 17.28 | 2.927 × 10-5 | 0.9507 | 923.8 | / | / | 364.0 | 83.07 |

| 72 h | 12.02 | 3.899 × 10-5 | 0.9131 | 357.6 | / | / | 405.7 | 1570 |

图7d为不同试样的动电位极化曲线。从图中可以明显看出,镁合金基体的阳极极化曲线并未见明显的钝化区,主要发生的是镁的活性溶解反应。而超双疏试样(以浸泡0 h时未产生点蚀的试样为例)的阳极极化曲线在-1.19~-1.12 V区域出现了钝化区,这是由于超双疏膜层对基体的保护作用,但随着电位正移,超双疏膜层被破坏,试样表面产生点蚀,暴露的基体发生溶解反应,导致腐蚀电流密度急剧升高。从极化曲线的阳极部分看出,超双疏试样的腐蚀电流密度始终远小于基体,耐蚀性能更优。此外,相较于镁合金裸样,超双疏试样腐蚀电位明显正移,腐蚀电流密度减小。其中镁合金基体的腐蚀电流密度是1.659 × 10-4 A·cm-2,而超双疏试样的腐蚀电流密度是9.759 × 10-7 A·cm-2。与镁基体相比,超双疏试样的腐蚀电流密度降低了2个数量级,提高了镁合金的耐蚀性。即使将超双疏试样在3.5%NaCl溶液中浸泡72 h,其腐蚀电位依然比裸样更正,仍保持较好的耐蚀性。

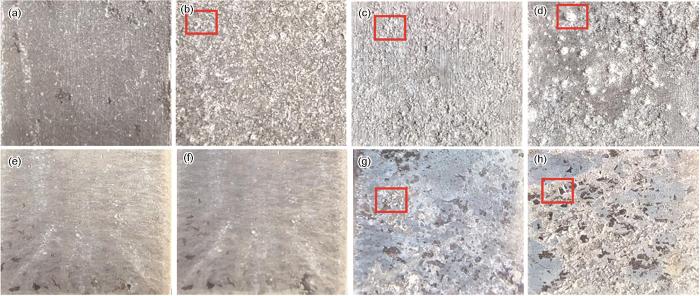

此外,图9分别为镁基体和超双疏试样在3.5%NaCl溶液中浸泡2、12、48和72 h的表面宏观形貌图。从图中可以观察到在浸泡2 h后的镁合金基体表面出现明显的腐蚀痕迹,大部分表面被腐蚀产物覆盖,并且随着浸泡时间的延长,溶液中越来越多的结晶NaCl颗粒沉积在其表面,如图中标记所示,并在浸泡48 h后,其表面出现了明显的腐蚀坑;而超双疏试样浸泡2 h后,其表面产生了不明显的点蚀,随着浸泡时间的延长,点蚀面积逐渐扩大,并在48 h的浸泡实验后,NaCl颗粒沿着因腐蚀暴露的基体处沉积附着。从整体的腐蚀形貌可以看出超双疏涂层在浸泡前期对镁合金基体有明显的保护作用,但浸泡时间增加后,其腐蚀防护效果减弱。

图9

图9

试样在3.5%NaCl溶液中浸泡不同时间的表面宏观形貌图

Fig.9

Macromorphologies of bare sample (a-d) and superampiphobic sample (e-h) after immersed in 3.5%NaCl solution for 2 h (a, e), 12 h (b, f), 48 h (c, g) and 72 h (d, h)

3 结论

(1) 采用硝酸溶液刻蚀结合氟硅烷修饰的方法,在AZ31B镁合金基体上制备了超双疏表面,最佳条件是:刻蚀时间4 min,氟硅烷修饰1 h。在此条件下制备得到的样品表面,水/乙二醇的接触角为159.3°/155.2°。

(2) 与镁合金基体相比,超双疏处理后的镁合金腐蚀电位正移了297 mV,腐蚀电流密度降低了2个数量级,电荷转移电阻提升了2个数量级,其耐蚀性得到了提升。

参考文献

Long-term corrosion behaviour of stainless steels in marine atmosphere

[J].

Study of the corrosion characteristics of the metal materials of an aero-engine under a marine atmosphere

[J].

Superamphiphobic blood-repellent surface modification of porous fluoropolymer membranes for blood oxygenation applications

[J].

Study of novel, thermally resistant Mg alloy with dual-phase

[J].A novel, thermally resistant, dual-phase Mg alloy was prepared, and the microstructural evolution and tensile properties were investigated. The results showed that the Mg alloy matrix mainly consisted of the α-Mg and β-Li phases, and the solidified microstructure was gradually refined with increasing ZrO2 incorporation. The tensile properties of the extruded and annealed alloys were markedly improved with increasing ZrO2 content. After annealing at 603 K for 8 h, the alloy strength remained almost stable, whereas the plasticity increased. Analysis of the evolution of the properties and fracture morphology showed that this type of Mg alloy possessed good thermal resistance and formability.

Biomimetic ultra-bubble-repellent surfaces based on a self-organized honeycomb film

[J].The adhesion of bubbles underwater remains the greatest cause of malfunctions in applications such as microfluidics, medical devices and heat exchangers. There is therefore an emerging need for ultra-bubble-repellent surfaces. Inspired by fish scales, which show high bubble repellency due to their hydrophilic nature and surface microstructures, we propose a novel method for preparing ultra-bubble-repellent surfaces by the hydrophilic treatment of self-organized microstructures. When in contact with air bubbles underwater, the artificial hydrophilic microstructured surfaces had a higher contact angle and a lower adhesion force than a flat surface. The mechanism leading to these properties is also investigated. Our method for the fabrication of ultra-bubble-repellent, hydrophilic, microstructured surfaces is simple and cost-effective, opening the way for its application in artificial devices, such as the inner surfaces of tubes, medical devices, and heat exchangers.

Facile preparation of superamphiphobic phosphate-Cu coating on iron substrate with mechanical stability, anti-frosting properties, and corrosion resistance

[J].

Mimicking the hierarchical surface topography and superhydrophobicity of the lotus leaf on magnesium alloy AZ31

[J].

Preparation of superamphiphobic surface on Al-alloy and its corrosion resistance

[J].

铝合金超双疏表面的制备及其耐蚀性研究

[J].采用盐溶液刻蚀和水浴处理的方法,结合氟硅烷的表面修饰,在5083铝合金基体上制备出了超双疏表面。采用场发射扫描电子显微镜 (FE-SEM)、X射线衍射 (XRD)、X射线光电子能谱 (XPS)、接触角测量和电化学测试等方法研究了超双疏铝合金表面的微观形貌、化学成分、疏水疏油性和耐蚀性。结果表明,水和乙二醇在该表面上的接触角分别为 158°和154.3°,展现出良好的超双疏性能;与基体相比,超双疏试样的腐蚀电位明显正移,腐蚀电流密度由4.016×10<sup>-6</sup> A·cm<sup>-2</sup>下降至1.531×10<sup>-7</sup> A·cm<sup>-2</sup>;在3.5% (质量分数) NaCl溶液中浸泡5 d后,超双疏试样的电荷转移电阻仍明显高于基体,提高了5083铝合金基体的耐蚀性。

Superhydrophobic photothermal icephobic surfaces based on candle soot

[J].Ice accumulation causes various problems in our daily life for human society. The daunting challenges in ice prevention and removal call for novel efficient antiicing strategies. Recently, photothermal materials have gained attention for creating icephobic surfaces owing to their merits of energy conservation and environmental friendliness. However, it is always challenging to get an ideal photothermal material which is cheap, easily fabricating, and highly photothermally efficient. Here, we demonstrate a low-cost, high-efficiency superhydrophobic photothermal surface, uniquely based on inexpensive commonly seen candle soot. It consists of three components: candle soot, silica shell, and polydimethylsiloxane (PDMS) brushes. The candle soot provides hierarchical nano/microstructures and photothermal ability, the silica shell strengthens the hierarchical candle soot, and the grafted low-surface-energy PDMS brushes endow the surface with superhydrophobicity. Upon illumination under 1 sun, the surface temperature can increase by 53 °C, so that no ice can form at an environmental temperature as low as -50 °C and it can also rapidly melt the accumulated frost and ice in 300 s. The superhydrophobicity enables the melted water to slide away immediately, leaving a clean and dry surface. The surface can also self-clean, which further enhances its effectiveness by removing dust and other contaminants which absorb and scatter sunlight. In addition, after oxygen plasma treatment, the surface can restore superhydrophobicity with sunlight illumination. The presented icephobic surface shows great potential and broad impacts owing to its inexpensive component materials, simplicity, ecofriendliness, and high energy efficiency.

A novel strategy for fabricating robust superhydrophobic fabrics by environmentally-friendly enzyme etching

[J].Superhydrophobic silk fabrics were prepared using an environmentally friendly enzyme-etching approach, followed by the modification with methyltrichlorosilane (MTCS) via a simple thermal chemical vapor deposition (CVD) process at 70 degrees C. The effects of the concentration, treatment time and temperature of enzyme on the etched surface properties were discussed. The composite superhydrophobic silk fabrics demonstrated excellent self-cleaning ability, relatively unscathed effecting their intrinsic properties such as the luster, softness, color and style of the fabrics. Furthermore, these treated fabrics demonstrated excellent mechanical durability after silane-treatment as evidenced by the cyclic abrasion and laundering tests. The composite superhydrophobic cotton fabrics have also demonstrated a high efficiency in oil-water separation. The facile technology via enzymatic hydrolysis to etch the substrate possesses extensive potential applications on various other cellulose-based substrates.

Rapid immobilization of simulated radioactive soil waste by microwave sintering

[J].A rapid and efficient method is particularly necessary in the timely disposal of seriously radioactive contaminated soil. In this paper, a series of simulated radioactive soil waste containing different contents of neodymium oxide (3-25wt.%) has been successfully vitrified by microwave sintering at 1300°C for 30min. The microstructures, morphology, element distribution, density and chemical durability of as obtained vitrified forms have been analyzed. The results show that the amorphous structure, homogeneous element distribution, and regular density improvement are well kept, except slight cracks emerge on the magnified surface for the 25wt.% NdO-containing sample. Moreover, all the vitrified forms exhibit excellent chemical durability, and the leaching rates of Nd are kept as ∼10-10g/(mday) within 42days. This demonstrates a potential application of microwave sintering in radioactive contaminated soil disposal.Copyright © 2017 Elsevier B.V. All rights reserved.

Influence of trace As content on the microstructure and corrosion behavior of the AZ91 alloy in different metallurgical conditions

[J].

A rapid two-step method for fabrication of superhydrophobic-superoleophobic nickel/copper alloy coating with self-cleaning and anticorrosion properties

[J].

One-step solve-thermal process for the construction of anticorrosion bionic superhydrophobic surfaces on magnesium alloy

[J].

Rapid fabrication of large-area, corrosion-resistant superhydrophobic Mg alloy surfaces

[J].

Fabrication and corrosion resistance of superhydrophobic magnesium alloy

[J].

Fabrication of a super-hydrophobic surface on a magnesium alloy by a simple method

[J].

A electro-deposition process for fabrication of biomimetic super-hydrophobic surface and its corrosion resistance on magnesium alloy

[J].

Fabrication of superhydrophobic magnesium alloy through the oxidation of hydrogen peroxide

[J].

Controlling wettability for improved corrosion inhibition on magnesium alloy as biomedical implant materials

[J].

Effects of surface treatments and bonding types on the interfacial behavior of fiber metal laminate based on magnesium alloy

[J].

Advance in structural classification and stability study of superamphiphobic surfaces

[J].

The variation of surface free energy of Al during superhydrophobicity processing

[J].

The potential of the superhydrophobic state to protect magnesium alloy against corrosion

[J].We describe the technologically simple route for the fabrication of the superhydrophobic coatings on top of wrought magnesium alloy MA8 based on nanosecond laser processing followed by the chemical vapor deposition of fluorosilane. The chemical and phase composition, surface morphologies, and variation of the coating wettability during prolonged contact with 0.5 NaCl solution or with salt aerosol were characterized using X-ray diffraction, FT-IR spectroscopy, scanning electron microscopy measurements, and the wettability analysis. The as-prepared coatings demonstrate corrosion current of more than eight orders of magnitude lower, while after 30 days of sample immersion into corrosive solution, the current was four orders of magnitude lower than that obtained for a polished sample which was for only 2 h in contact with electrolyte. The mechanisms of the protective activity of fabricated coatings were discussed.

Local and global electrochemical impedances applied to the corrosion behaviour of an AZ91 magnesium alloy

[J].

An easy and environmentally-friendly approach to superamphiphobicity of aluminum surfaces

[J].

Robust superhydrophobic surface with wrinkle-like structures on AZ31 alloy that repels viscous oil and investigations of the anti-icing property

[J].

Effect of hierarchical precipitates on corrosion behavior of fine-grain magnesium-gadolinium-silver alloy

[J].

Bioinspired construction of Mg-Li alloys surfaces with stable superhydrophobicity and improved corrosion resistance

[J].A facile method was utilized for the construction of the bioinspired superhydrophobic Mg–Li alloy surfaces with peonylike micronanoscale hierarchical structures. The resultant materials were characterized by scanning electron microscope, x-ray photoelectron spectroscopy, and water contact angle measurements. The obtained Mg–Li alloy surfaces presented the dramatically improved corrosion resistance and long-term stable superhydrophobic properties with a static water contact angle of about 160° and a small sliding angle of less than 5°, which may extend the practical application of Mg–Li alloys in industrial and high-technology fields.