近年来,工业化进程发展迅速,海洋工程装备迎来全新的发展机遇。然而,海水的盐度较高会导致金属腐蚀的发生,造成大量的经济损失。因此,钢结构的保护越来越受到人们的重视[1,2]。常用的金属腐蚀防护的方法主要有电化学防护[3,4]、缓蚀剂防护[5,6]、金属表面处理[7,8]以及有机涂层防护[9,10]。有机涂层防护作为一种简单有效的金属防护手段已经得到了广泛的应用[11]。目前工程中常常采用底漆加面漆的双层涂料或者底漆、中间漆加面漆的三层涂料的施工工艺。相比于油性涂料,水性漆具有低毒、环保的优点,以水作为分散介质,大大降低了有害性挥发性有机物(VOCs)的排放,符合可持续发展和生态文明建设的要求[12,13]。水性聚氨酯面漆由于具有良好的机械性能、耐磨性、柔韧性的特点引起人们的广泛关注[14~20]。但为了使聚氨酯在水中具有良好的分散性,在制备的过程中将主链中引入了大量的亲水基团,从而使主链的亲水性增加,这也导致了聚氨酯的耐水性降低,严重影响涂层的腐蚀防护性能[21,22]。并且,水性聚氨酯还存在着热稳定性差、耐溶剂性差等不足,限制了在生产生活中的大规模应用。因此,需要对水性聚氨酯进行改性才能提升聚氨酯的防腐性能,扩大其应用规模[23]。

SiO2气凝胶(SiO2 aerogel)作为一种新型非晶材料,具有独特的三维网状结构,由于其低密度、高孔隙率的特点,能够提高涂层的耐开裂收缩、耐老化的性能[24,25]。将SiO2气凝胶加入水性聚氨酯涂层后,能够阻挡腐蚀性离子(Cl-、H2O、O2等)的渗透,并且SiO2气凝胶能够吸水膨胀,促使涂层的阻挡能力增强,显著增强涂层的耐蚀性能。然而,传统的SiO2气凝胶质量较轻并且具有较高的疏水性,浮于水性聚氨酯的上层并且分散性较差,容易团聚,产生更多的腐蚀通路,不利于涂层耐蚀性能的提高。因此,进行亲水改性可以有效的提升其在水性聚氨酯中的分散性和相容性,提高涂层的致密度。何方[26]等人通过利用表面活性剂3-氨丙基三羟基硅烷在SiO2气凝胶表面接枝氨基、羟基等亲水性基团,形成了外亲内疏的结构,促使改性后的SiO2气凝胶在水性聚合物中均匀分散。卢斌等[27]利用爱利索RM-825稳定剂对SiO2气凝胶表面进行改性,稳定剂本身携带电荷,通过稳定剂在SiO2气凝胶表面的吸附,改变SiO2气凝胶表面的电荷分布,通过同种电荷的相互排斥作用,克服SiO2气凝胶之间大的范德华力,达到均匀分散的目的。

本文利用脲醛对SiO2气凝胶进行亲水改性,提高SiO2气凝胶在水性聚氨酯中的分散性和与涂层的相容性,提高涂层的耐蚀性能。将不同比例的SiO2气凝胶和改性后SiO2气凝胶作为填料,添加到水性聚氨酯中,制备复合涂层。通过红外分析、扫描电镜分析、电化学测试、附着力试验、中性盐雾试验测试等对涂层的结构、耐腐蚀等性能进行了详细的研究。

1 实验方法

使用粒径为40~200 nm疏水SiO2气凝胶配制质量分数为16.7%乙醇SiO2气凝胶溶液,然后配制尿素饱和溶液,按照SiO2气凝胶乙醇溶液与尿素饱和溶液质量比为10∶3的比例混合上述溶液,磁力搅拌1 h后,加入盐酸,调节pH = 1后,加入4.8 mL甲醛,95℃水浴中搅拌6 h后离心,用去离子水洗涤数次,并在100℃的烘箱中烘干。

称取固化剂与树脂质量比1∶5的水性环氧富锌底漆(WBEZRC),再以底漆与水质量比5∶1的比例称取水。先加入固化剂,再加入溶剂水,充分混合搅拌均匀后,再加入树脂。最后加入5滴水性消泡剂,超声30 min去除气泡。

先称取面漆,再按照面漆与水质量比5∶1的比例加入水作为溶剂。加入不同比例的改性前后的SiO2气凝胶(0.5%、1%、2%),超声分散30 min后搅拌12 h,使填料与水性聚氨酯混合均匀。按面漆+溶剂与固化剂质量比5∶1的比例加入固化剂,最后加入5~6滴水性消泡剂,超声30 min去除气泡。

基材为10 mm × 10 mm与50 mm × 50 mm的Q235钢,打磨后用无水乙醇洗净晾干,将配制好的水性环氧富锌底漆用旋涂仪涂敷到Q235钢上,在室温下干燥96 h后,60℃烘箱干燥4 h,然后将配制好的水性聚氨酯涂料用旋涂仪涂敷到水性环氧富锌底漆上,在室温下干燥96 h后,60℃烘箱干燥4 h底漆膜厚控制在100 ± 5 μm,面漆膜厚控制在100 ± 5 μm。

通过IS50 Fourier红外光谱(FT-IR)获得填料官能团类型和化学结构,Gemini SEM 300扫描电子显微镜(SEM)观察形貌。采用POWEREACH接触角测量仪测试涂层的亲疏水性。通过DeFelsko PosiTestAT-A附着力测定仪测定涂层与界面之间的结合力。采用CS350电化学工作站在3.5% (质量分数)NaCl溶液中测试涂层的电化学行为,工作电极为涂层电极,参比电极为Ag/AgCl电极,对电极为碳棒,测量的范围在105~10-2 Hz之间,电压为10 mV。中性盐雾试验根据GB/T1771-2007测试涂层的耐蚀性,将涂敷涂层后带有划痕的钢板(50 mm × 50 mm × 2 mm)置于盐雾箱中,并连续喷涂5%NaCl溶液。

2 结果与分析

2.1 红外分析

采用红外分析的方法分析未改性SiO2气凝胶与改性SiO2气凝胶(SiO2 aerogel M)的结构。如图1所示,在红外光谱中,对于未改性的SiO2气凝胶,1080 cm-1处的吸收峰是由于Si-O-Si基团的非对称伸缩振动引起的,Si-O-Si的弯曲振动峰位于463 cm-1处,960 cm-1处的吸收峰代表了Si-OH基团。对于改性后的气相SiO2,Si-O-Si的伸缩振动峰和弯曲振动峰的位置均没有较大的改变,说明对SiO2气凝胶的改性没有对其原本的结构产生破坏。经过改性的SiO2气凝胶在3349 cm-1处出现了NH基团的伸缩振动峰,在1626和1570 cm-1处的吸收峰属于-CO-NH2的吸收带,1388 cm-1处的吸收峰是由于-CH2的变形振动引起的,而在波数1037.7 cm-1的吸收峰可能是由于脲醛与SiO2气凝胶发生了化学反应形成了C-O-Si基团的缘故,说明成功对SiO2气凝胶进行了亲水改性。

图1

图1

改性前后SiO2气凝胶的FTIR光谱图

Fig.1

FTIR spectra of silica aerogel before and after modification

2.2 SEM测试

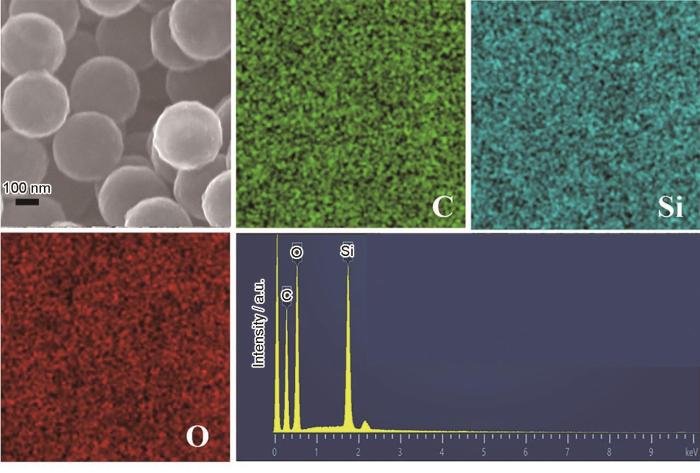

图2为SiO2气凝胶的表面SEM形貌,可以看出SiO2气凝胶是球状小颗粒呈无规则堆叠排列的,其中存在着大量孔隙,通过EDS能谱分析可以看出SiO2气凝胶表面主要包含C、O、Si 3种元素。

图2

图2

SiO2气凝胶的SEM形貌图、元素映射图和EDS谱图

Fig.2

SEM image of SiO2 aerogel, elemental map scannings of C, Si and O, and EDS spectrum

2.3 接触角

采用接触角测试可以有效表征添加改性SiO2气凝胶与未改性SiO2气凝胶涂层的亲疏水性的变化。如图3所示,空白水性聚氨酯涂层的水接触角为59.83°,然而添加SiO2气凝胶后,涂层的水接触角得到了明显的提升。其中添加1% SiO2硅气凝胶涂层的水接触角从59.83°提高到了82.70°,说明SiO2气凝胶的加入提升了涂层的疏水性和抗渗性能。而添加改性SiO2气凝胶的水性聚氨酯涂层的接触角普遍略低于同等添加量未改性SiO2气凝胶的涂层的接触角,间接证明了SiO2的亲水改性,数值差别不大说明亲水改性手段对涂层接触角的影响较小。

图3

图3

不同聚氨酯复合涂层的接触角图

Fig.3

Contact angles of polyurethane composite coatings containing unmodified and modified SiO2 aerogels

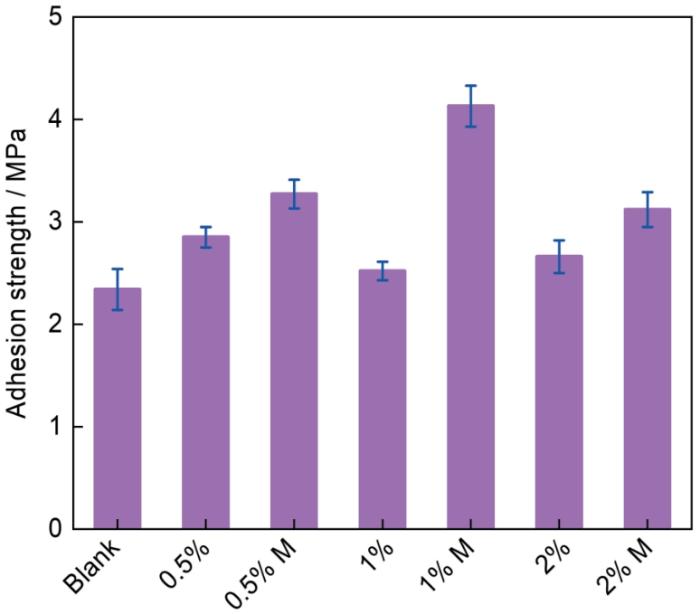

2.4 附着力

附着力同样是表征涂层防护性能的重要手段之一,附着力高说明涂层与金属界面的结合性能好,能更好地抑制电化学腐蚀反应对涂层和界面的破坏。如图4所示,通过比较不同涂层样品的附着力,可以看到添加改性后SiO2气凝胶聚氨酯复合涂层的附着力要明显高于添加未改性SiO2气凝胶聚氨酯复合涂层的附着力,原因是亲水改性提高了SiO2气凝胶在水性聚氨酯中的分散性,能够抑制涂层固化过程中微裂纹的扩展,降低了涂层内和界面处的缺陷,迟滞延缓了应力的释放,提高了界面结合力。其中含有1%亲水改性的SiO2气凝胶的样品具有最佳的附着力,达到4 MPa以上,间接说明1%的比例是改性SiO2添加的最合适比例。

图4

图4

不同涂层附着力测试对比图

Fig.4

Comparison of adhesions of polyurethane composite coatings containing unmodified and modified SiO2 aerogels

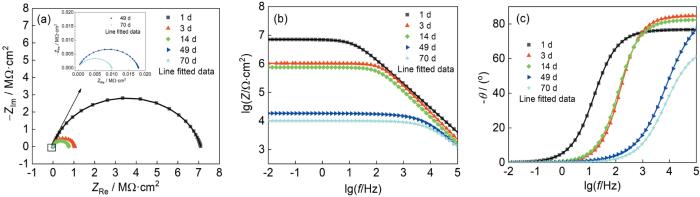

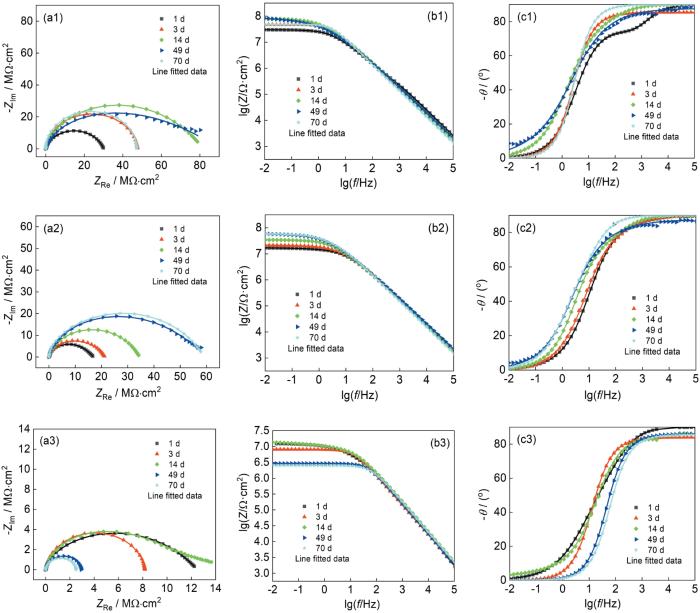

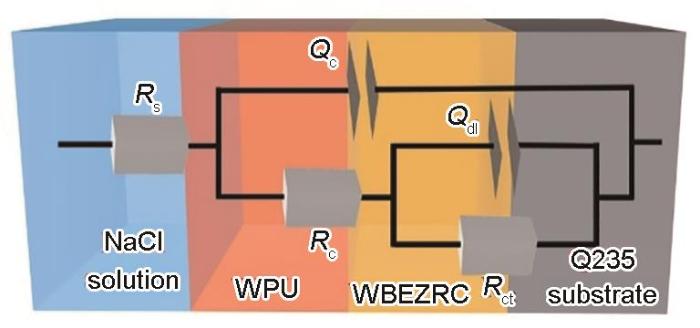

2.5 电化学阻抗测试

图5为不同涂层浸泡在3.5% NaCl溶液中1、3、14、49、70 d的EIS图。空白涂层初始的低频阻抗在106~107 Ω·cm2左右,相位角在90°以下。在浸泡过程中,空白涂层低频阻抗模值和容抗半径整体呈现下降的趋势。49 d后涂层的低频阻抗模值和容抗半径低于5 × 105 Ω·cm2,可能是由于在浸泡过程中,水分子和腐蚀性介质逐渐进入到涂层中,破坏了涂层的阻隔作用,导致涂层对金属基体保护作用下降,说明空白涂层长效防腐性能较差。

图5

图5

空白聚氨酯涂层的EIS曲线

Fig.5

Nyquist (a), impedance module (b) and phase angle (c) plots of EIS curves of blank polyurethane coating

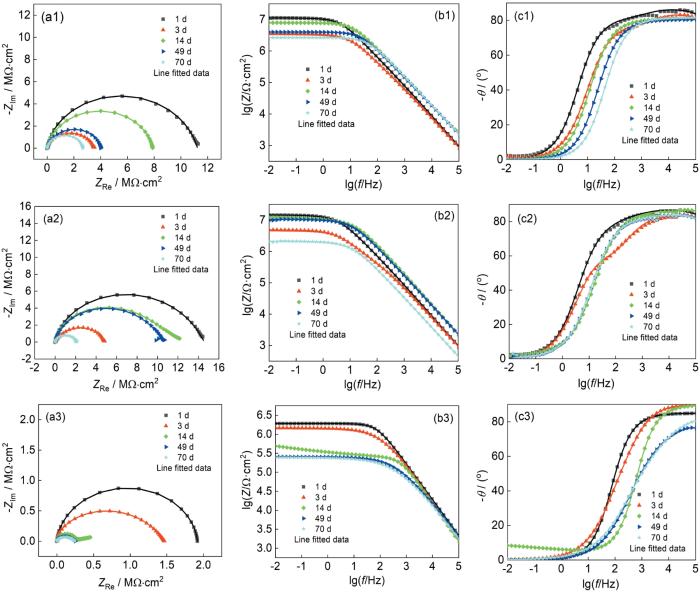

如图6所示,添加未改性的SiO2气凝胶后,涂层的阻抗和容抗半径发生了明显的变化。添加0.5%未改性SiO2气凝胶和1%未改性SiO2气凝胶的水性聚氨酯涂层,涂层的阻抗和容抗半径得到了明显的提高,添加2%未改性SiO2气凝胶的水性聚氨酯涂层的阻抗和容抗半径在浸泡初期略低于空白水性聚氨酯涂层,这是由于填料的加入提高了涂层的阻隔作用,使涂层对Cl-、H2O等腐蚀性介质的阻挡作用进一步加强,而过多的添加量使得填料的团聚现象加剧,产生更多的缺陷,降低深层的防腐性能。其中添加1% SiO2气凝胶的涂层具有最强的防腐性能。

图6

图6

添加不同比例未改性SiO2气凝胶涂层的EIS曲线

Fig.6

Nyquist (a), impedance module (b) and phase angle (c) plots of EIS curves of polyurethane composite coatings containing different mass ratios of unmodified SiO2 aerogel (1, 2 and 3 represent the coatings containing 0.5%, 1% and 2% unmodified SiO2 aerogel, respectively)

如图7所示,添加经过亲水改性的SiO2气凝胶后,涂层的阻抗模值和容抗半径数值得到提高。随着浸泡时间的增加,涂层的阻抗和容抗半径数值在浸泡初期不断增大,这是由于亲水改性提高了涂层与SiO2气凝胶的相容性,提高了填料在水性聚氨酯中的分散性。另外,亲水改性的SiO2气凝胶吸水膨胀阻断了更多的腐蚀通路,使涂层的防腐性能得到明显提高。其中如图7a2所示,添加1%亲水改性的SiO2气凝胶在浸泡70 d后,其阻抗和容抗半径提高最大,阻抗值超过6 × 107 Ω·cm2,具有最高的阻抗和容抗半径。说明添加1%亲水改性的SiO2气凝胶水性聚氨酯复合涂层具有最优异的长效防腐性能。此外,添加2%亲水改性的SiO2气凝胶水性聚氨酯复合涂层的阻抗值在浸泡14 d后下降明显,说明较高的填料掺杂量降低了涂层的长效防腐性能。

图7

图7

添加不同比例改性SiO2气凝胶涂层的EIS曲线

Fig.7

Nyquist (a), module (b) and phase (c) plots of EIS curves of polyurethane composite coatings containing different mass ratios of modified SiO2 aerogel (1, 2 and 3 represent the coatings containing 0.5%, 1% and 2% modified SiO2 aerogel, respectively)

图8

表1 浸泡70 d后涂层的EIS拟合电路参数

Table 1

| Sample | Rc | CPE c | Cc F·cm-2 | Rct | CPEdl | Cdl F·cm-2 | ||

|---|---|---|---|---|---|---|---|---|

| Yc / F·cm-2·S n-1 | nc | Ydl / F·cm-2·S n-1 | ndl | |||||

| 0 | 1.19 × 103 | 2.82 × 10-7 | 0.75 | 3.09 × 10-8 | 8.89 × 103 | 7.50 × 10-24 | 0.02 | 1.29 × 10-27 |

| 1% SiO2 | 8.16 × 104 | 8.84 × 10-9 | 0.95 | 7.35 × 10-9 | 2.06 × 106 | 6.87 × 10-8 | 0.52 | 2.1 × 10-8 |

| 1% SiO2 M | 1.63 × 107 | 1.05 × 10-9 | 0.99 | 1.05 × 10-9 | 4.29 × 107 | 5.95 × 10-9 | 0.65 | 5.11 × 10-9 |

从表1中可以看出,添加1%改性后SiO2气凝胶的水性聚氨酯涂层具有最低的涂层电容和最高的电荷转移电阻,证明了添加1%改性后SiO2气凝胶的水性聚氨酯涂层具有最好的耐蚀性能。

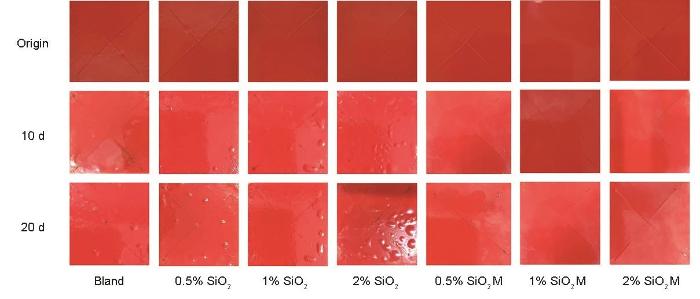

2.6 盐雾试验

盐雾试验是评价腐蚀性介质在涂层中扩散能力的重要手段。通过20 d的盐雾试验,可以看到添加未改性的SiO2气凝胶的水性涂层均出现了明显的鼓泡现象,说明添加SiO2气凝胶聚氨酯复合涂层的耐盐雾性能较差;添加改性后SiO2气凝胶的聚氨酯涂层表面没有明显的起泡和剥离现象。其中添加1%改性SiO2气凝胶的聚氨酯涂层表面和初始涂层一样光滑,没有点蚀痕迹,说明此时涂层具有最优异的耐盐雾性能,亲水改性提高了填料在涂层中的的分散性和长期耐腐蚀性能。

图9

图9

不同聚氨酯复合涂层20 d盐雾实验后的宏观表面形貌

Fig.9

Macro-morphologies of various as-prepared polyurethane composite coatings after salt spray test for 0-20 d

3 结论

利用脲醛成功对SiO2气凝胶进行了亲水改性,并成功制备了SiO2气凝胶水性聚氨酯复合涂层,研究表明添加改性后SiO2气凝胶的涂层能够显著提高水性聚氨酯涂层的耐蚀性能。测试结果表明:

(1) 对SiO2气凝胶亲水改性后,涂层的接触角和附着力以及涂层的耐蚀性能明显提高,说明亲水改性可以提高SiO2气凝胶在水性涂料中的分散性和相容性。

(2) 通过电化学阻抗测试得出添加1%亲水改性的SiO2气凝胶的涂层具有最大的低频阻抗模值,证明了添加1%改性后SiO2气凝胶的水性聚氨酯涂层具有最好的耐蚀性能。

(3) 经过20 d的盐雾试验添加1%亲水改性的SiO2气凝胶聚氨酯涂层没有明显的腐蚀起泡现象,说明涂层具有优异的长期防腐性能。

参考文献

Research progress of nanofillers for epoxy anti-corrosion coatings

[J].

纳米填料在环氧防腐涂层中的应用研究进展

[J].

Smart ZnS@C filler for super-anticorrosive self-healing zinc-rich epoxy coating

[J].

Protective effect of impressed current method on Q235A steel in simulated splash zone

[J].

外加电流法对Q235A钢在模拟浪花飞溅区的保护效果

[J].

Electrochemical cathodic protection powered by triboelectric nanogenerator

[J].

Core-shell mesoporous silica-metal-phenolic network microcapsule for the controlled release of corrosion inhibitor

[J].

Ionic liquids as green and sustainable steel corrosion inhibitors: recent developments

[J].

Comparative analysis of corrosion resistance in molten aluminum of H13 Steel with different surface treatments

[J].H13 steel specimens were subjected to nitriding and sulphonitrocarburizing treatments after vacuum heat treatment, and then immersed in 700℃ high temperature molten aluminum for corrosion test. And the cross-section microstructure, mass loss and phase composition of the specimens before and after corrosion were analyzed in detail. The results show that the interface bonding mode of infiltration layer is similar for the nitrided specimen and the sulphonitrocarburizing specimen, which is smooth and dense, the boundary between layer and matrix is relatively flat. There are Fe<sub>3</sub>N, Fe<sub>2</sub>N, FeS, Fe<sub>3</sub>C phases in the surface compound area of the sulphonitrocarburized specimen, with the FeS phase being a typical close-packed hexagonal crystal structure with higher hardness. There are Fe<sub>3</sub>N and Fe<sub>2</sub>N phases in the surface compound area of the nitrided specimen, and the surface hardness of which is higher than that of the sulphonitrocarburized specimen. Under the same corrosion conditions, the mass loss and mass loss rate of the vacuum heat treated specimen are 7.5 g and 21.1%, respectively, those of the nitrided specimen are 4.1 g and 11.2%, respectively, those of the sulphonitrocarburized specimen are 0.8 g and 2.2%, respectively. The iron-aluminum compound of the specimens is embedded in the steel matrix in a zigzag shape, and the thickness is 184.75, 88.56 and 35.88 μm, respectively. The main compound after corrosion by molten aluminum is Fe<sub>2</sub>Al<sub>5</sub>, and the sulphonitrocarburized specimen can form FeS and Fe<sub>3</sub>C with the H13 steel matrix due to the addition of S and C, showing the best high temperature corrosion resistance in molten aluminum.

不同表面处理的H13钢耐铝液腐蚀的对比分析

[J].

Improvement of zero valent iron nanoparticles by ultrasound-assisted synthesis, study of Cr(VI) removal and application for the treatment of metal surface processing wastewater

[J].

Recent advances in bio-inspired multifunctional coatings for corrosion protection

[J].

A self-healing polyurethane-based composite coating with high strength and anti-corrosion properties for metal protection

[J].

Smart protective coatings with self-sensing and active corrosion protection dual functionality from pH-sensitive calcium carbonate microcontainers

[J].

Influence of polyhydroxy hyperdispersant on anti-corrosion property of waterborne epoxy coatings

[J].

多羟基超分散剂对水性环氧涂层防腐性能的影响

[J].通过开路电位测量、电化学阻抗谱测试、动电位极化曲线测试、附着力测试等手段,研究了多羟基超分散剂对水性环氧清漆防腐性能的影响。结果表明,在3.5%NaCl溶液中,环氧清漆和含分散剂的环氧清漆的失效历程相同,可分为4个阶段:涂层快速吸水阶段、涂层腐蚀产物生成阶段、稳定腐蚀阶段和腐蚀产物扩散阶段。含分散剂的环氧清漆表现为较强的吸水性,多羟基超分散剂增加了涂层的饱和吸水率,加快了涂层的腐蚀失效。

Preparation and performance study of waterborne epoxy anticorrosive coating material

[J].

水性环氧防腐涂料的制备与性能研究

[J].

Current status of research on waterborne polyurethane coatings

[J].

水性聚氨酯涂料的研究现状

[J].

Novel waterborne poly(urethane-urea)/silica nanocomposites

[J].

An investigation of primer adhesion and topcoat compatibility on the waterborne intumescent coating to structural steel

[J].The adhesion and compatibility between various layers within an intumescent coating system coated on steel plate is studied under ambient condition and at elevated temperature as per cellulosic fire heating regime. An intumescent coating system, which typically comprises of a primer layer, an intumescent coating layer and a topcoat, must strongly adhere to the steel structure during service period for an effective protection and foamed char should also be tightly intact on the structure. The adhesion of different anti-corrosive primers such as epoxy coating, alkyd coating and zinc silicate coating with steel plate and the subsequent intumescent coating along with various topcoats viz. polyurethane coating, alkyd coating and acrylic coating are evaluated by X-cut tape test and pull-off test methods. The microstructure of interface between the steel plate and the coating system layers is characterized by field emission scanning electron microscope. The compatibility of coating system and thermal properties of coatings were measured by thermal insulation performance and thermogravimetric analysis respectively. The role played by type of primer and topcoat for an intumescent coating on the performance of coating system has been established.

Silver(I) complex with a Schiff base ligand extended waterborne polyurethane: a developed strategy to obtain a highly stable antibacterial dispersion impregnated with in situ formed silver nanoparticles

[J].

Functional nano-fillers in waterborne polyurethane/acrylic composites and the thermal, mechanical, and dielectrical properties

[J].

Advances in waterborne polyurethane and polyurethane-urea dispersions and their eco-friendly derivatives: a review

[J].Polyurethanes and polyurethane-ureas, particularly their water-based dispersions, have gained relevance as an extremely versatile area based on environmentally friendly approaches. The evolution of their synthesis methods, and the nature of the reactants (or compounds involved in the process) towards increasingly sustainable pathways, has positioned these dispersions as a relevant and essential product for diverse application frameworks. Therefore, in this work, it is intended to show the progress in the field of polyurethane and polyurethane-urea dispersions over decades, since their initial synthesis approaches. Thus, the review covers from the basic concepts of polyurethane chemistry to the evolution of the dispersion’s preparation strategies. Moreover, an analysis of the recent trends of using renewable reactants and enhanced green strategies, including the current legislation, directed to limit the toxicity and potentiate the sustainability of dispersions, is described. The review also highlights the strengths of the dispersions added with diverse renewable additives, namely, cellulose, starch or chitosan, providing some noteworthy results. Similarly, dispersion’s potential to be processed by diverse methods is shown, evidencing, with different examples, their suitability in a variety of scenarios, outstanding their versatility even for high requirement applications.

Self-healing waterborne polyurethane coating by pH-dependent triggered-release mechanism

[J].

Study on epoxy resin-organic silicon composite modified waterborne polyurethane temperature-resistant anticorrosive coating

[J].

环氧树脂-有机硅复合改性水性聚氨酯耐温防腐涂料的研究

[J].

Functionalization and properties of waterborne polyurethane coatings

[J].

水性聚氨酯涂料的功能化及性能

[J].

Research on abrasive resistance and self-matting properties of silicone-modified waterborne polyurethane coating

[J].

有机硅改性水性聚氨酯涂层耐磨自消光性能研究

[J].

Preparation and properties of SiO2 aerogel thermal insulation packaging material

[J].

SiO2气凝胶隔热保温包装材料的制备及其性能研究

[J].为了提高包装材料隔热保温性能,以SiO<sub>2</sub>气凝胶(SA,silica aerogel )为改性剂,对低密度聚乙烯(LDPE,low density polyethylene)进行改性,采用共混流延法制备了具有优异隔热保温性能包装薄膜。研究了不同浓度SiO<sub>2</sub>气凝胶对薄膜的力学性能、阻隔性能、亲疏水性能、热稳定性、导热系数等的影响,并设计隔热保温实验验证薄膜的保温性能。结果表明,二氧化硅气凝胶添加量为6%(质量分数)的薄膜综合性能最好,其导热系数达到了0.07 W/(m·K),并且具有良好的力学性能、阻隔性能、亲疏水性能和热稳定性,为其在食品包装中的应用提供了实验基础。

Effect of silica aerogel on thermal insulation and acoustic absorption of geopolymer foam composites: the role of aerogel particle size

[J].

Surface modification of aerogel microspheres and its effect on thermal insulation coatings

[J].

气凝胶微球表面改性及对隔热涂料的影响

[J].