Corrosion behavior of PANI nanofiber/modified GO/waterborne epoxy composite coating on stainless steel

1

2022

... 水性涂料因挥发性有机化合物(VOC)含量低、涂层附着力强、成本低及在潮湿环境中可直接涂覆施工等优点,成为目前主要的防腐手段[1].但水性涂料对基材的表面清洁度要求更高,并且水的蒸发潜热大,涂层的表干时间长,表面张力大.同时,水性涂料固化后残存的亲水基团会导致涂层层间附着力差,涂层的耐水性、耐腐蚀性变差,容易出现闪蚀与透蚀等现象[2,3].因此,急需对水性涂料进行改进. ...

不锈钢表面聚苯胺纳米纤维/改性氧化石墨烯/水性环氧复合涂层的制备与防护性能研究

1

2022

... 水性涂料因挥发性有机化合物(VOC)含量低、涂层附着力强、成本低及在潮湿环境中可直接涂覆施工等优点,成为目前主要的防腐手段[1].但水性涂料对基材的表面清洁度要求更高,并且水的蒸发潜热大,涂层的表干时间长,表面张力大.同时,水性涂料固化后残存的亲水基团会导致涂层层间附着力差,涂层的耐水性、耐腐蚀性变差,容易出现闪蚀与透蚀等现象[2,3].因此,急需对水性涂料进行改进. ...

Advantages and disadvantages of water-based coating

1

2015

... 水性涂料因挥发性有机化合物(VOC)含量低、涂层附着力强、成本低及在潮湿环境中可直接涂覆施工等优点,成为目前主要的防腐手段[1].但水性涂料对基材的表面清洁度要求更高,并且水的蒸发潜热大,涂层的表干时间长,表面张力大.同时,水性涂料固化后残存的亲水基团会导致涂层层间附着力差,涂层的耐水性、耐腐蚀性变差,容易出现闪蚀与透蚀等现象[2,3].因此,急需对水性涂料进行改进. ...

水性涂料的优势及面临的问题

1

2015

... 水性涂料因挥发性有机化合物(VOC)含量低、涂层附着力强、成本低及在潮湿环境中可直接涂覆施工等优点,成为目前主要的防腐手段[1].但水性涂料对基材的表面清洁度要求更高,并且水的蒸发潜热大,涂层的表干时间长,表面张力大.同时,水性涂料固化后残存的亲水基团会导致涂层层间附着力差,涂层的耐水性、耐腐蚀性变差,容易出现闪蚀与透蚀等现象[2,3].因此,急需对水性涂料进行改进. ...

Research progress in modification and anti-corrosion properties of waterborne coatings

1

2019

... 水性涂料因挥发性有机化合物(VOC)含量低、涂层附着力强、成本低及在潮湿环境中可直接涂覆施工等优点,成为目前主要的防腐手段[1].但水性涂料对基材的表面清洁度要求更高,并且水的蒸发潜热大,涂层的表干时间长,表面张力大.同时,水性涂料固化后残存的亲水基团会导致涂层层间附着力差,涂层的耐水性、耐腐蚀性变差,容易出现闪蚀与透蚀等现象[2,3].因此,急需对水性涂料进行改进. ...

水性防腐蚀涂料的改性及其防腐蚀性能研究进展

1

2019

... 水性涂料因挥发性有机化合物(VOC)含量低、涂层附着力强、成本低及在潮湿环境中可直接涂覆施工等优点,成为目前主要的防腐手段[1].但水性涂料对基材的表面清洁度要求更高,并且水的蒸发潜热大,涂层的表干时间长,表面张力大.同时,水性涂料固化后残存的亲水基团会导致涂层层间附着力差,涂层的耐水性、耐腐蚀性变差,容易出现闪蚀与透蚀等现象[2,3].因此,急需对水性涂料进行改进. ...

Study on the corrosion protection mechanism of graphene modified anticorrosive coatings

1

2017

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

石墨烯改性防腐涂料的防腐机理研究

1

2017

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

Preparation and anticorrosion performance of M-phenylenediamine-graphene oxide/organic coating

1

2021

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

间苯二胺-氧化石墨烯/有机涂层的制备及防腐性能研究

1

2021

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

Surface modification mechanism of graphene oxide by adding rare earths

1

2018

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

氧化石墨烯表面稀土改性机理

1

2018

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

Preparation, corrosion-and wear-resistance of polymethyl methacrylate coating modified with particles of basalt/cerium oxide composite

1

2022

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

玄武岩/氧化铈改性PMMA涂层的防腐及耐磨性能的研究

1

2022

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

Microstructure and properties of rare earth CeO2-doped graphene composite coatings prepared by MAO on AA7050

1

2021

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

Effects of rare earth metal oxide doping on micromorphology and corrosion behavior of hydroxyapatite-graphene oxide composite coating fabriacted on AZ91 magnesium alloy

1

2021

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

Polypyrrole/graphene nanosheets/rare earth ions/dodecyl benzene sulfonic acid nanocomposite as a highly effective anticorrosive coating

1

2016

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

Facile fabrication and corrosion behavior of iron and iron-reduced graphene oxide composite coatings by electroless plating from baths containing no reducing agent

1

2016

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

Superior corrosion resistance and self-healable epoxy coating pigmented with silanzied trianiline-intercalated graphene

1

2019

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

Anticorrosive durability of zinc-based waterborne coatings enhanced by highly dispersed and conductive polyaniline/graphene oxide composite

1

2018

... 石墨烯具有小尺寸效应、二维片层结构与疏水性,可作为纳米填料来提高涂料的防腐性能[4, 5].但石墨烯在涂料中分散性和润湿性差会严重影响涂层的防腐性能,所以需要对石墨烯表面进行改性.稀土元素(RE)电负性低、活性大,不仅可以洁净石墨烯表面还可以形成RE-C键或混合杂化使其状态更稳定[6,7].Zong等[8]在7050高强铝合金表面加入氧化铈(CeO2)和石墨烯制备涂层.涂层微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),且此时的自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳.Liang等[9]将稀土氧化物(La2O3和Y2O3)分散在羟基磷灰石(HA)-氧化石墨烯(GO)复合涂料中制备涂层.与纯HA-GO涂层相比,添加RE后的HA-GO复合涂层组织均匀,Y2O3与HA形成了无序的网状结构,La2O3形成了“海胆”状结构,均提高了HA-GO复合涂层的耐蚀性.Alam等[10]制备了聚吡咯(Py)/石墨烯纳米片(GNS)/稀土离子(RE3+ = La3+、Sm3+、Nd3+)/十二烷基苯磺酸(DBSA)纳米复合涂层.同时,含有GNS和RE元素的聚吡啶涂层具有最高的电荷转移电阻(Rct)和最低的双层电容(Cdl),耐腐蚀性能最好.这是因为涂层基体中纳米颗粒分布均匀,有利于在钢表面形成均匀的钝化膜.Zhang等[11]在碱性镀液的Cu表面制备了Fe镀层和Fe-rGO复合镀层.结果表明,GO提高了复合镀层组织的致密性,使得Fe基镀层的耐腐蚀能力大幅提高.Ye等[12]将硅烷化苯胺三聚体(SAT)和石墨烯合成的SAT-G加入纯环氧涂层中,结果表明加入0.5% SAT-G的复合涂层长期耐蚀能力显著提高.Xiao等[13]将聚苯胺(PANI)分散在GO中制备PAGO复合材料,加入0.5% PAGO的锌基水性涂料涂层具有更好的阴极保护作用和阻隔性能,涂层的耐蚀性明显提高. ...

1

2003

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

1

2003

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

Effect of base metal surface treatment on adhesion and capacitive behavior of organic coatings

1

2020

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

基底金属表面处理对有机涂层附着力和电容行为的影响

1

2020

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

Effect of substrate surface state on adhesion of silane epoxy hybrid resin coating/2024 aluminium alloy

1

2016

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

基体表面状态对硅烷环氧杂化树脂涂层/2024铝合金间附着力影响

1

2016

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

Superhydrophobic carbon nanotubes/epoxy nanocomposite coating by facile one-step spraying

1

2018

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

Preparation and characterization of fluorocarbon-multiwall carbon nanotube composite coatings

1

2016

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

氟碳漆/碳纳米管导电防腐涂层的制备及表征

1

2016

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

Anti-corrosion effect of magnesium phosphate cement coating on carbon steel

1

2017

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

碳钢表面磷酸镁水泥涂层的防腐性研究

1

2017

... 优质的涂料是实现高性能涂层的基础,但涂料只是涂层的半成品,涂层性能才是最终评价涂料的标准.然而涂层性能的好坏不仅取决于涂料本身的质量,更大程度取决于涂装的工艺过程与条件[14].董佳晨等[15]在除油打磨、不做处理、泛锈与全锈4种Q235钢表面制备涂层.对比看出,打磨后基体的粗糙度最高,涂层比不做处理和生锈表面的附着力都强.生锈基体涂层由于锈层的存在,腐蚀介质更容易通过涂层,涂层附着力下降.王浩伟等[16]采用机械、脱脂、热碱清洗以及络酸盐钝化4种方式对铝合金表面进行处理.其中,热碱清洗能够为涂层提供较好的极性附着表面,对涂层附着力的提高更为显著.Zhang等[17]利用喷涂法制备了碳纳米管(CNTs)/环氧树脂复合涂层.结果表明,随着CNTs含量的增加,涂层表面粗糙度由(2.98 ± 0.51) μm增加到(25.45 ± 0.44) μm,涂层表现出超疏水性,且具有高的耐腐蚀性和电导率.李娟等[18]利用刷涂法制备氟碳漆/CNTs防腐导电涂层,结果表明复合涂层在300℃以下极为稳定,复合涂层中形成了网状导电结构.董英豪[19]利用手工涂刷制备磷酸镁水泥涂层.结果表明涂层的线性极化电阻(Rp)基本维持在2.0 × 105 Ω·cm2,Rct始终保持在8 × 104 Ω·cm2左右,粘结强度为4.8 ± 0.7 MPa,表明涂层具有较好的防腐作用. ...

1

1999

... 涂层与基体附着力按GB/T 9286-1998[20]划格法测量,附着力等级分为0~5级.涂层硬度按GB/T 6739-2006[21]铅笔硬度计测量,测试铅笔为三菱铅笔(9B-9H).采用Dataphysics OCA20型接触角测试仪测定涂层与基材的静态水接触角,采用ZDY方法[22]计算涂层的表面能,见 式(1).将制备的涂层涂覆在自制的三电极体系上,暴露面积为1 cm2,在3.5%NaCl电解质溶液中浸泡2 h,待开路电位(OCP)平稳后(5 min内变化小于10 mV),用CHI600E电化学工作站测量OCP、极化(Tafel)曲线和电化学阻抗谱(EIS). ...

1

1999

... 涂层与基体附着力按GB/T 9286-1998[20]划格法测量,附着力等级分为0~5级.涂层硬度按GB/T 6739-2006[21]铅笔硬度计测量,测试铅笔为三菱铅笔(9B-9H).采用Dataphysics OCA20型接触角测试仪测定涂层与基材的静态水接触角,采用ZDY方法[22]计算涂层的表面能,见 式(1).将制备的涂层涂覆在自制的三电极体系上,暴露面积为1 cm2,在3.5%NaCl电解质溶液中浸泡2 h,待开路电位(OCP)平稳后(5 min内变化小于10 mV),用CHI600E电化学工作站测量OCP、极化(Tafel)曲线和电化学阻抗谱(EIS). ...

1

2007

... 涂层与基体附着力按GB/T 9286-1998[20]划格法测量,附着力等级分为0~5级.涂层硬度按GB/T 6739-2006[21]铅笔硬度计测量,测试铅笔为三菱铅笔(9B-9H).采用Dataphysics OCA20型接触角测试仪测定涂层与基材的静态水接触角,采用ZDY方法[22]计算涂层的表面能,见 式(1).将制备的涂层涂覆在自制的三电极体系上,暴露面积为1 cm2,在3.5%NaCl电解质溶液中浸泡2 h,待开路电位(OCP)平稳后(5 min内变化小于10 mV),用CHI600E电化学工作站测量OCP、极化(Tafel)曲线和电化学阻抗谱(EIS). ...

1

2007

... 涂层与基体附着力按GB/T 9286-1998[20]划格法测量,附着力等级分为0~5级.涂层硬度按GB/T 6739-2006[21]铅笔硬度计测量,测试铅笔为三菱铅笔(9B-9H).采用Dataphysics OCA20型接触角测试仪测定涂层与基材的静态水接触角,采用ZDY方法[22]计算涂层的表面能,见 式(1).将制备的涂层涂覆在自制的三电极体系上,暴露面积为1 cm2,在3.5%NaCl电解质溶液中浸泡2 h,待开路电位(OCP)平稳后(5 min内变化小于10 mV),用CHI600E电化学工作站测量OCP、极化(Tafel)曲线和电化学阻抗谱(EIS). ...

Novel characterization of wetting properties and the calculation of liquid-solid interface tension (Ⅱ)

1

2007

... 涂层与基体附着力按GB/T 9286-1998[20]划格法测量,附着力等级分为0~5级.涂层硬度按GB/T 6739-2006[21]铅笔硬度计测量,测试铅笔为三菱铅笔(9B-9H).采用Dataphysics OCA20型接触角测试仪测定涂层与基材的静态水接触角,采用ZDY方法[22]计算涂层的表面能,见 式(1).将制备的涂层涂覆在自制的三电极体系上,暴露面积为1 cm2,在3.5%NaCl电解质溶液中浸泡2 h,待开路电位(OCP)平稳后(5 min内变化小于10 mV),用CHI600E电化学工作站测量OCP、极化(Tafel)曲线和电化学阻抗谱(EIS). ...

润湿性表征体系及液固界面张力计算的新方法(Ⅱ)

1

2007

... 涂层与基体附着力按GB/T 9286-1998[20]划格法测量,附着力等级分为0~5级.涂层硬度按GB/T 6739-2006[21]铅笔硬度计测量,测试铅笔为三菱铅笔(9B-9H).采用Dataphysics OCA20型接触角测试仪测定涂层与基材的静态水接触角,采用ZDY方法[22]计算涂层的表面能,见 式(1).将制备的涂层涂覆在自制的三电极体系上,暴露面积为1 cm2,在3.5%NaCl电解质溶液中浸泡2 h,待开路电位(OCP)平稳后(5 min内变化小于10 mV),用CHI600E电化学工作站测量OCP、极化(Tafel)曲线和电化学阻抗谱(EIS). ...

Preparation of graphene oxide modified by titanium dioxide to enhance the anti-corrosion performance of epoxy coatings

1

2015

... 图1为稀土铈改性石墨烯/水性环氧树脂复合涂料的组织结构.图1a为改性石墨烯的TEM图.可见,GO的片层非常薄,呈半透明薄纱状,片层上均匀的附着一层纳米颗粒,片层上有部分褶皱,但仍有大面积的平展部分.这说明经过超声处理后,氧化石墨烯片层已被充分分散在环氧树脂中.图1b为改性石墨烯的高分辨电镜(HREM)图.可见石墨烯片层的晶格条纹,估计原子层数约为5~7层.还能非常清晰观察到石墨烯表面纳米粒子的晶格条纹,其快速傅里叶变换(FFT)结果准确对应为立方氧化铈结构,表明石墨烯上原位生长的纳米粒子有非常好的结晶性.通过Digital Micrograph软件算出CeO2@rGO的晶粒尺寸平均仅有(1.7 ± 0.5) nm,形状为不规则的多边形.图1c为纯水性环氧树脂涂料及稀土铈改性石墨烯/水性环氧树脂复合涂料的XRD谱.可见,稀土铈改性石墨烯在2θ = 28.6°、33.1°、47.4°和56.4°处出现属于CeO2 (111)、(200)、(220)、(311)4个晶面的衍射峰(JCPDF No.34-0394).对于环氧涂料,其在10°~50°之间出现了由固化环氧树脂分子散射所引起的宽而弥散的衍射峰[23, 24],表明了环氧树脂的无定形性质.而复合涂料与环氧涂料的衍射峰类似,并未出现稀土铈改性石墨烯的特征峰.对此主要是石墨烯的添加量较少,低于X射线衍射检测极限[25,26].其次,石墨烯在涂料中的剥离与随机排列的程度越高,石墨烯衍射峰强度降低[27~29].图1d为纯水性环氧树脂涂料、稀土铈改性石墨烯/水性环氧树脂复合涂料及氧化石墨烯的FT-IR图谱.可见,3390 cm-1左右的峰为O-H的吸收峰,2970与2870 cm-1为CH3中C-H键的对称与反对称伸缩振动吸收峰;2930 cm-1是CH2中C-H键的不对称吸收峰.1606与1511 cm-1处的峰对应苯环骨架-C=C-的特征吸收峰;1296、1247 cm-1与1117、1037 cm-1处的吸收带属于芳香醚键与脂肪醚键C-O-C的对称与不对称伸缩振动吸收峰.830 cm-1处属于苯环中C-H键的面外弯曲振动,560 cm-1处属于C-C键的面外弯曲振动[30].添加稀土铈改性石墨烯后的水性环氧树脂的特征峰位置未发生明显变化,表明改性石墨烯的引入未改变水性环氧树脂的结构,两者之间属于物理结合[31]. ...

Effect of high gamma irradiation doses on structure and morphology properties for Epoxy resins

1

2021

... 图1为稀土铈改性石墨烯/水性环氧树脂复合涂料的组织结构.图1a为改性石墨烯的TEM图.可见,GO的片层非常薄,呈半透明薄纱状,片层上均匀的附着一层纳米颗粒,片层上有部分褶皱,但仍有大面积的平展部分.这说明经过超声处理后,氧化石墨烯片层已被充分分散在环氧树脂中.图1b为改性石墨烯的高分辨电镜(HREM)图.可见石墨烯片层的晶格条纹,估计原子层数约为5~7层.还能非常清晰观察到石墨烯表面纳米粒子的晶格条纹,其快速傅里叶变换(FFT)结果准确对应为立方氧化铈结构,表明石墨烯上原位生长的纳米粒子有非常好的结晶性.通过Digital Micrograph软件算出CeO2@rGO的晶粒尺寸平均仅有(1.7 ± 0.5) nm,形状为不规则的多边形.图1c为纯水性环氧树脂涂料及稀土铈改性石墨烯/水性环氧树脂复合涂料的XRD谱.可见,稀土铈改性石墨烯在2θ = 28.6°、33.1°、47.4°和56.4°处出现属于CeO2 (111)、(200)、(220)、(311)4个晶面的衍射峰(JCPDF No.34-0394).对于环氧涂料,其在10°~50°之间出现了由固化环氧树脂分子散射所引起的宽而弥散的衍射峰[23, 24],表明了环氧树脂的无定形性质.而复合涂料与环氧涂料的衍射峰类似,并未出现稀土铈改性石墨烯的特征峰.对此主要是石墨烯的添加量较少,低于X射线衍射检测极限[25,26].其次,石墨烯在涂料中的剥离与随机排列的程度越高,石墨烯衍射峰强度降低[27~29].图1d为纯水性环氧树脂涂料、稀土铈改性石墨烯/水性环氧树脂复合涂料及氧化石墨烯的FT-IR图谱.可见,3390 cm-1左右的峰为O-H的吸收峰,2970与2870 cm-1为CH3中C-H键的对称与反对称伸缩振动吸收峰;2930 cm-1是CH2中C-H键的不对称吸收峰.1606与1511 cm-1处的峰对应苯环骨架-C=C-的特征吸收峰;1296、1247 cm-1与1117、1037 cm-1处的吸收带属于芳香醚键与脂肪醚键C-O-C的对称与不对称伸缩振动吸收峰.830 cm-1处属于苯环中C-H键的面外弯曲振动,560 cm-1处属于C-C键的面外弯曲振动[30].添加稀土铈改性石墨烯后的水性环氧树脂的特征峰位置未发生明显变化,表明改性石墨烯的引入未改变水性环氧树脂的结构,两者之间属于物理结合[31]. ...

Epoxy/graphene nanocomposites prepared by in-situ microwaving

1

2021

... 图1为稀土铈改性石墨烯/水性环氧树脂复合涂料的组织结构.图1a为改性石墨烯的TEM图.可见,GO的片层非常薄,呈半透明薄纱状,片层上均匀的附着一层纳米颗粒,片层上有部分褶皱,但仍有大面积的平展部分.这说明经过超声处理后,氧化石墨烯片层已被充分分散在环氧树脂中.图1b为改性石墨烯的高分辨电镜(HREM)图.可见石墨烯片层的晶格条纹,估计原子层数约为5~7层.还能非常清晰观察到石墨烯表面纳米粒子的晶格条纹,其快速傅里叶变换(FFT)结果准确对应为立方氧化铈结构,表明石墨烯上原位生长的纳米粒子有非常好的结晶性.通过Digital Micrograph软件算出CeO2@rGO的晶粒尺寸平均仅有(1.7 ± 0.5) nm,形状为不规则的多边形.图1c为纯水性环氧树脂涂料及稀土铈改性石墨烯/水性环氧树脂复合涂料的XRD谱.可见,稀土铈改性石墨烯在2θ = 28.6°、33.1°、47.4°和56.4°处出现属于CeO2 (111)、(200)、(220)、(311)4个晶面的衍射峰(JCPDF No.34-0394).对于环氧涂料,其在10°~50°之间出现了由固化环氧树脂分子散射所引起的宽而弥散的衍射峰[23, 24],表明了环氧树脂的无定形性质.而复合涂料与环氧涂料的衍射峰类似,并未出现稀土铈改性石墨烯的特征峰.对此主要是石墨烯的添加量较少,低于X射线衍射检测极限[25,26].其次,石墨烯在涂料中的剥离与随机排列的程度越高,石墨烯衍射峰强度降低[27~29].图1d为纯水性环氧树脂涂料、稀土铈改性石墨烯/水性环氧树脂复合涂料及氧化石墨烯的FT-IR图谱.可见,3390 cm-1左右的峰为O-H的吸收峰,2970与2870 cm-1为CH3中C-H键的对称与反对称伸缩振动吸收峰;2930 cm-1是CH2中C-H键的不对称吸收峰.1606与1511 cm-1处的峰对应苯环骨架-C=C-的特征吸收峰;1296、1247 cm-1与1117、1037 cm-1处的吸收带属于芳香醚键与脂肪醚键C-O-C的对称与不对称伸缩振动吸收峰.830 cm-1处属于苯环中C-H键的面外弯曲振动,560 cm-1处属于C-C键的面外弯曲振动[30].添加稀土铈改性石墨烯后的水性环氧树脂的特征峰位置未发生明显变化,表明改性石墨烯的引入未改变水性环氧树脂的结构,两者之间属于物理结合[31]. ...

Study of electroless plating Cu by reduced graphene oxide and the effects on the microstructures and properties of RGO/Cu composites

1

2018

... 图1为稀土铈改性石墨烯/水性环氧树脂复合涂料的组织结构.图1a为改性石墨烯的TEM图.可见,GO的片层非常薄,呈半透明薄纱状,片层上均匀的附着一层纳米颗粒,片层上有部分褶皱,但仍有大面积的平展部分.这说明经过超声处理后,氧化石墨烯片层已被充分分散在环氧树脂中.图1b为改性石墨烯的高分辨电镜(HREM)图.可见石墨烯片层的晶格条纹,估计原子层数约为5~7层.还能非常清晰观察到石墨烯表面纳米粒子的晶格条纹,其快速傅里叶变换(FFT)结果准确对应为立方氧化铈结构,表明石墨烯上原位生长的纳米粒子有非常好的结晶性.通过Digital Micrograph软件算出CeO2@rGO的晶粒尺寸平均仅有(1.7 ± 0.5) nm,形状为不规则的多边形.图1c为纯水性环氧树脂涂料及稀土铈改性石墨烯/水性环氧树脂复合涂料的XRD谱.可见,稀土铈改性石墨烯在2θ = 28.6°、33.1°、47.4°和56.4°处出现属于CeO2 (111)、(200)、(220)、(311)4个晶面的衍射峰(JCPDF No.34-0394).对于环氧涂料,其在10°~50°之间出现了由固化环氧树脂分子散射所引起的宽而弥散的衍射峰[23, 24],表明了环氧树脂的无定形性质.而复合涂料与环氧涂料的衍射峰类似,并未出现稀土铈改性石墨烯的特征峰.对此主要是石墨烯的添加量较少,低于X射线衍射检测极限[25,26].其次,石墨烯在涂料中的剥离与随机排列的程度越高,石墨烯衍射峰强度降低[27~29].图1d为纯水性环氧树脂涂料、稀土铈改性石墨烯/水性环氧树脂复合涂料及氧化石墨烯的FT-IR图谱.可见,3390 cm-1左右的峰为O-H的吸收峰,2970与2870 cm-1为CH3中C-H键的对称与反对称伸缩振动吸收峰;2930 cm-1是CH2中C-H键的不对称吸收峰.1606与1511 cm-1处的峰对应苯环骨架-C=C-的特征吸收峰;1296、1247 cm-1与1117、1037 cm-1处的吸收带属于芳香醚键与脂肪醚键C-O-C的对称与不对称伸缩振动吸收峰.830 cm-1处属于苯环中C-H键的面外弯曲振动,560 cm-1处属于C-C键的面外弯曲振动[30].添加稀土铈改性石墨烯后的水性环氧树脂的特征峰位置未发生明显变化,表明改性石墨烯的引入未改变水性环氧树脂的结构,两者之间属于物理结合[31]. ...

石墨烯化学镀铜及其对石墨烯/铜基复合材料组织性能的影响

1

2018

... 图1为稀土铈改性石墨烯/水性环氧树脂复合涂料的组织结构.图1a为改性石墨烯的TEM图.可见,GO的片层非常薄,呈半透明薄纱状,片层上均匀的附着一层纳米颗粒,片层上有部分褶皱,但仍有大面积的平展部分.这说明经过超声处理后,氧化石墨烯片层已被充分分散在环氧树脂中.图1b为改性石墨烯的高分辨电镜(HREM)图.可见石墨烯片层的晶格条纹,估计原子层数约为5~7层.还能非常清晰观察到石墨烯表面纳米粒子的晶格条纹,其快速傅里叶变换(FFT)结果准确对应为立方氧化铈结构,表明石墨烯上原位生长的纳米粒子有非常好的结晶性.通过Digital Micrograph软件算出CeO2@rGO的晶粒尺寸平均仅有(1.7 ± 0.5) nm,形状为不规则的多边形.图1c为纯水性环氧树脂涂料及稀土铈改性石墨烯/水性环氧树脂复合涂料的XRD谱.可见,稀土铈改性石墨烯在2θ = 28.6°、33.1°、47.4°和56.4°处出现属于CeO2 (111)、(200)、(220)、(311)4个晶面的衍射峰(JCPDF No.34-0394).对于环氧涂料,其在10°~50°之间出现了由固化环氧树脂分子散射所引起的宽而弥散的衍射峰[23, 24],表明了环氧树脂的无定形性质.而复合涂料与环氧涂料的衍射峰类似,并未出现稀土铈改性石墨烯的特征峰.对此主要是石墨烯的添加量较少,低于X射线衍射检测极限[25,26].其次,石墨烯在涂料中的剥离与随机排列的程度越高,石墨烯衍射峰强度降低[27~29].图1d为纯水性环氧树脂涂料、稀土铈改性石墨烯/水性环氧树脂复合涂料及氧化石墨烯的FT-IR图谱.可见,3390 cm-1左右的峰为O-H的吸收峰,2970与2870 cm-1为CH3中C-H键的对称与反对称伸缩振动吸收峰;2930 cm-1是CH2中C-H键的不对称吸收峰.1606与1511 cm-1处的峰对应苯环骨架-C=C-的特征吸收峰;1296、1247 cm-1与1117、1037 cm-1处的吸收带属于芳香醚键与脂肪醚键C-O-C的对称与不对称伸缩振动吸收峰.830 cm-1处属于苯环中C-H键的面外弯曲振动,560 cm-1处属于C-C键的面外弯曲振动[30].添加稀土铈改性石墨烯后的水性环氧树脂的特征峰位置未发生明显变化,表明改性石墨烯的引入未改变水性环氧树脂的结构,两者之间属于物理结合[31]. ...

A facile approach to chemically modified graphene and its polymer nanocomposites

1

2012

... 图1为稀土铈改性石墨烯/水性环氧树脂复合涂料的组织结构.图1a为改性石墨烯的TEM图.可见,GO的片层非常薄,呈半透明薄纱状,片层上均匀的附着一层纳米颗粒,片层上有部分褶皱,但仍有大面积的平展部分.这说明经过超声处理后,氧化石墨烯片层已被充分分散在环氧树脂中.图1b为改性石墨烯的高分辨电镜(HREM)图.可见石墨烯片层的晶格条纹,估计原子层数约为5~7层.还能非常清晰观察到石墨烯表面纳米粒子的晶格条纹,其快速傅里叶变换(FFT)结果准确对应为立方氧化铈结构,表明石墨烯上原位生长的纳米粒子有非常好的结晶性.通过Digital Micrograph软件算出CeO2@rGO的晶粒尺寸平均仅有(1.7 ± 0.5) nm,形状为不规则的多边形.图1c为纯水性环氧树脂涂料及稀土铈改性石墨烯/水性环氧树脂复合涂料的XRD谱.可见,稀土铈改性石墨烯在2θ = 28.6°、33.1°、47.4°和56.4°处出现属于CeO2 (111)、(200)、(220)、(311)4个晶面的衍射峰(JCPDF No.34-0394).对于环氧涂料,其在10°~50°之间出现了由固化环氧树脂分子散射所引起的宽而弥散的衍射峰[23, 24],表明了环氧树脂的无定形性质.而复合涂料与环氧涂料的衍射峰类似,并未出现稀土铈改性石墨烯的特征峰.对此主要是石墨烯的添加量较少,低于X射线衍射检测极限[25,26].其次,石墨烯在涂料中的剥离与随机排列的程度越高,石墨烯衍射峰强度降低[27~29].图1d为纯水性环氧树脂涂料、稀土铈改性石墨烯/水性环氧树脂复合涂料及氧化石墨烯的FT-IR图谱.可见,3390 cm-1左右的峰为O-H的吸收峰,2970与2870 cm-1为CH3中C-H键的对称与反对称伸缩振动吸收峰;2930 cm-1是CH2中C-H键的不对称吸收峰.1606与1511 cm-1处的峰对应苯环骨架-C=C-的特征吸收峰;1296、1247 cm-1与1117、1037 cm-1处的吸收带属于芳香醚键与脂肪醚键C-O-C的对称与不对称伸缩振动吸收峰.830 cm-1处属于苯环中C-H键的面外弯曲振动,560 cm-1处属于C-C键的面外弯曲振动[30].添加稀土铈改性石墨烯后的水性环氧树脂的特征峰位置未发生明显变化,表明改性石墨烯的引入未改变水性环氧树脂的结构,两者之间属于物理结合[31]. ...

Toward effective and tunable interphases in graphene oxide/epoxy composites by grafting different chain lengths of polyetheramine onto graphene oxide

1

2014

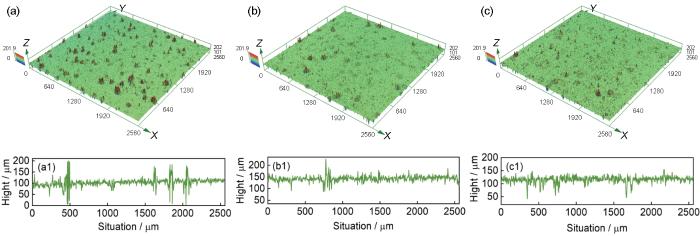

... 图3为不同涂装方式制备的稀土铈改性石墨烯/水性环氧树脂复合涂层在钢基体上的表面和截面SEM图.可见,复合涂层表面出现较多凸起结构(图3a~c).从局部放大照片可见(图3a1~c1),基体磨痕被遮盖,涂层呈现出灰色背景和黑点两个明显特征.灰色背景表明石墨烯在环氧基体中能够实现良好的分散[28],而由于石墨烯大的比表面积与范德华力,部分石墨烯在环氧基体中发生团聚,形成不同大小的黑点.综合可知凸起结构为树脂包裹的团聚石墨烯.从局部放大SEM图可见,喷涂涂层相比滚涂法和刷涂法涂层,表面的凸起数量最多,分布最为均匀.对此认为主要与涂装方式有关,即部分团聚的石墨烯颗粒会在涂布器和羊毛刷的作用下被带出基体表面,而这些较重的涂料颗粒仍能够在压缩空气作用下被涂覆在基体表面.因此喷涂法制备的涂层的成分均匀性高于滚涂法和刷涂法.喷涂涂层截面比较光滑致密(图3a2),涂层与基体之间的结合紧密,裂缝的数量与长度较少,框选区域可见涂层中属于石墨烯的“蝉翼状”片层结构.滚涂涂层截面粗糙(图3b2),涂层中的片层结构不明显.刷涂涂层截面致密(图3c2),涂层与基体的结合紧密,在涂层上方存在明显的片层堆积结构.总的来说3种涂装方式制备的涂层与基体的结合均较为紧密,表明石墨烯的引入能够增强涂层与基体的结合.此外石墨烯能够作为涂层中的强化相,提高涂层的硬度,使得涂层截面在磨削后更为光滑.由图可见,采用不同涂装方式制备的涂层厚度具有较大差异,这是因为喷涂过程中,压缩空气对涂料分子施加冲击力,使得涂料分子间的堆积密度增加,涂层的致密性增加.而滚涂法依靠线棒涂布器施加压力,刷涂依靠羊毛刷施以压力. ...

Highly orientated graphene/epoxy coating with exceptional anti-corrosion performance for harsh oxygen environments

1

2020

... 图1为稀土铈改性石墨烯/水性环氧树脂复合涂料的组织结构.图1a为改性石墨烯的TEM图.可见,GO的片层非常薄,呈半透明薄纱状,片层上均匀的附着一层纳米颗粒,片层上有部分褶皱,但仍有大面积的平展部分.这说明经过超声处理后,氧化石墨烯片层已被充分分散在环氧树脂中.图1b为改性石墨烯的高分辨电镜(HREM)图.可见石墨烯片层的晶格条纹,估计原子层数约为5~7层.还能非常清晰观察到石墨烯表面纳米粒子的晶格条纹,其快速傅里叶变换(FFT)结果准确对应为立方氧化铈结构,表明石墨烯上原位生长的纳米粒子有非常好的结晶性.通过Digital Micrograph软件算出CeO2@rGO的晶粒尺寸平均仅有(1.7 ± 0.5) nm,形状为不规则的多边形.图1c为纯水性环氧树脂涂料及稀土铈改性石墨烯/水性环氧树脂复合涂料的XRD谱.可见,稀土铈改性石墨烯在2θ = 28.6°、33.1°、47.4°和56.4°处出现属于CeO2 (111)、(200)、(220)、(311)4个晶面的衍射峰(JCPDF No.34-0394).对于环氧涂料,其在10°~50°之间出现了由固化环氧树脂分子散射所引起的宽而弥散的衍射峰[23, 24],表明了环氧树脂的无定形性质.而复合涂料与环氧涂料的衍射峰类似,并未出现稀土铈改性石墨烯的特征峰.对此主要是石墨烯的添加量较少,低于X射线衍射检测极限[25,26].其次,石墨烯在涂料中的剥离与随机排列的程度越高,石墨烯衍射峰强度降低[27~29].图1d为纯水性环氧树脂涂料、稀土铈改性石墨烯/水性环氧树脂复合涂料及氧化石墨烯的FT-IR图谱.可见,3390 cm-1左右的峰为O-H的吸收峰,2970与2870 cm-1为CH3中C-H键的对称与反对称伸缩振动吸收峰;2930 cm-1是CH2中C-H键的不对称吸收峰.1606与1511 cm-1处的峰对应苯环骨架-C=C-的特征吸收峰;1296、1247 cm-1与1117、1037 cm-1处的吸收带属于芳香醚键与脂肪醚键C-O-C的对称与不对称伸缩振动吸收峰.830 cm-1处属于苯环中C-H键的面外弯曲振动,560 cm-1处属于C-C键的面外弯曲振动[30].添加稀土铈改性石墨烯后的水性环氧树脂的特征峰位置未发生明显变化,表明改性石墨烯的引入未改变水性环氧树脂的结构,两者之间属于物理结合[31]. ...

An FT-IR investigation of epoxy coatings as a function of electrolyte composition

1

2012

... 图1为稀土铈改性石墨烯/水性环氧树脂复合涂料的组织结构.图1a为改性石墨烯的TEM图.可见,GO的片层非常薄,呈半透明薄纱状,片层上均匀的附着一层纳米颗粒,片层上有部分褶皱,但仍有大面积的平展部分.这说明经过超声处理后,氧化石墨烯片层已被充分分散在环氧树脂中.图1b为改性石墨烯的高分辨电镜(HREM)图.可见石墨烯片层的晶格条纹,估计原子层数约为5~7层.还能非常清晰观察到石墨烯表面纳米粒子的晶格条纹,其快速傅里叶变换(FFT)结果准确对应为立方氧化铈结构,表明石墨烯上原位生长的纳米粒子有非常好的结晶性.通过Digital Micrograph软件算出CeO2@rGO的晶粒尺寸平均仅有(1.7 ± 0.5) nm,形状为不规则的多边形.图1c为纯水性环氧树脂涂料及稀土铈改性石墨烯/水性环氧树脂复合涂料的XRD谱.可见,稀土铈改性石墨烯在2θ = 28.6°、33.1°、47.4°和56.4°处出现属于CeO2 (111)、(200)、(220)、(311)4个晶面的衍射峰(JCPDF No.34-0394).对于环氧涂料,其在10°~50°之间出现了由固化环氧树脂分子散射所引起的宽而弥散的衍射峰[23, 24],表明了环氧树脂的无定形性质.而复合涂料与环氧涂料的衍射峰类似,并未出现稀土铈改性石墨烯的特征峰.对此主要是石墨烯的添加量较少,低于X射线衍射检测极限[25,26].其次,石墨烯在涂料中的剥离与随机排列的程度越高,石墨烯衍射峰强度降低[27~29].图1d为纯水性环氧树脂涂料、稀土铈改性石墨烯/水性环氧树脂复合涂料及氧化石墨烯的FT-IR图谱.可见,3390 cm-1左右的峰为O-H的吸收峰,2970与2870 cm-1为CH3中C-H键的对称与反对称伸缩振动吸收峰;2930 cm-1是CH2中C-H键的不对称吸收峰.1606与1511 cm-1处的峰对应苯环骨架-C=C-的特征吸收峰;1296、1247 cm-1与1117、1037 cm-1处的吸收带属于芳香醚键与脂肪醚键C-O-C的对称与不对称伸缩振动吸收峰.830 cm-1处属于苯环中C-H键的面外弯曲振动,560 cm-1处属于C-C键的面外弯曲振动[30].添加稀土铈改性石墨烯后的水性环氧树脂的特征峰位置未发生明显变化,表明改性石墨烯的引入未改变水性环氧树脂的结构,两者之间属于物理结合[31]. ...

Effect of modified graphene on corrosion resistance of epoxy resin coating

1

2018

... 图1为稀土铈改性石墨烯/水性环氧树脂复合涂料的组织结构.图1a为改性石墨烯的TEM图.可见,GO的片层非常薄,呈半透明薄纱状,片层上均匀的附着一层纳米颗粒,片层上有部分褶皱,但仍有大面积的平展部分.这说明经过超声处理后,氧化石墨烯片层已被充分分散在环氧树脂中.图1b为改性石墨烯的高分辨电镜(HREM)图.可见石墨烯片层的晶格条纹,估计原子层数约为5~7层.还能非常清晰观察到石墨烯表面纳米粒子的晶格条纹,其快速傅里叶变换(FFT)结果准确对应为立方氧化铈结构,表明石墨烯上原位生长的纳米粒子有非常好的结晶性.通过Digital Micrograph软件算出CeO2@rGO的晶粒尺寸平均仅有(1.7 ± 0.5) nm,形状为不规则的多边形.图1c为纯水性环氧树脂涂料及稀土铈改性石墨烯/水性环氧树脂复合涂料的XRD谱.可见,稀土铈改性石墨烯在2θ = 28.6°、33.1°、47.4°和56.4°处出现属于CeO2 (111)、(200)、(220)、(311)4个晶面的衍射峰(JCPDF No.34-0394).对于环氧涂料,其在10°~50°之间出现了由固化环氧树脂分子散射所引起的宽而弥散的衍射峰[23, 24],表明了环氧树脂的无定形性质.而复合涂料与环氧涂料的衍射峰类似,并未出现稀土铈改性石墨烯的特征峰.对此主要是石墨烯的添加量较少,低于X射线衍射检测极限[25,26].其次,石墨烯在涂料中的剥离与随机排列的程度越高,石墨烯衍射峰强度降低[27~29].图1d为纯水性环氧树脂涂料、稀土铈改性石墨烯/水性环氧树脂复合涂料及氧化石墨烯的FT-IR图谱.可见,3390 cm-1左右的峰为O-H的吸收峰,2970与2870 cm-1为CH3中C-H键的对称与反对称伸缩振动吸收峰;2930 cm-1是CH2中C-H键的不对称吸收峰.1606与1511 cm-1处的峰对应苯环骨架-C=C-的特征吸收峰;1296、1247 cm-1与1117、1037 cm-1处的吸收带属于芳香醚键与脂肪醚键C-O-C的对称与不对称伸缩振动吸收峰.830 cm-1处属于苯环中C-H键的面外弯曲振动,560 cm-1处属于C-C键的面外弯曲振动[30].添加稀土铈改性石墨烯后的水性环氧树脂的特征峰位置未发生明显变化,表明改性石墨烯的引入未改变水性环氧树脂的结构,两者之间属于物理结合[31]. ...

改性石墨烯对环氧树脂涂层耐腐蚀性能的影响

1

2018

... 图1为稀土铈改性石墨烯/水性环氧树脂复合涂料的组织结构.图1a为改性石墨烯的TEM图.可见,GO的片层非常薄,呈半透明薄纱状,片层上均匀的附着一层纳米颗粒,片层上有部分褶皱,但仍有大面积的平展部分.这说明经过超声处理后,氧化石墨烯片层已被充分分散在环氧树脂中.图1b为改性石墨烯的高分辨电镜(HREM)图.可见石墨烯片层的晶格条纹,估计原子层数约为5~7层.还能非常清晰观察到石墨烯表面纳米粒子的晶格条纹,其快速傅里叶变换(FFT)结果准确对应为立方氧化铈结构,表明石墨烯上原位生长的纳米粒子有非常好的结晶性.通过Digital Micrograph软件算出CeO2@rGO的晶粒尺寸平均仅有(1.7 ± 0.5) nm,形状为不规则的多边形.图1c为纯水性环氧树脂涂料及稀土铈改性石墨烯/水性环氧树脂复合涂料的XRD谱.可见,稀土铈改性石墨烯在2θ = 28.6°、33.1°、47.4°和56.4°处出现属于CeO2 (111)、(200)、(220)、(311)4个晶面的衍射峰(JCPDF No.34-0394).对于环氧涂料,其在10°~50°之间出现了由固化环氧树脂分子散射所引起的宽而弥散的衍射峰[23, 24],表明了环氧树脂的无定形性质.而复合涂料与环氧涂料的衍射峰类似,并未出现稀土铈改性石墨烯的特征峰.对此主要是石墨烯的添加量较少,低于X射线衍射检测极限[25,26].其次,石墨烯在涂料中的剥离与随机排列的程度越高,石墨烯衍射峰强度降低[27~29].图1d为纯水性环氧树脂涂料、稀土铈改性石墨烯/水性环氧树脂复合涂料及氧化石墨烯的FT-IR图谱.可见,3390 cm-1左右的峰为O-H的吸收峰,2970与2870 cm-1为CH3中C-H键的对称与反对称伸缩振动吸收峰;2930 cm-1是CH2中C-H键的不对称吸收峰.1606与1511 cm-1处的峰对应苯环骨架-C=C-的特征吸收峰;1296、1247 cm-1与1117、1037 cm-1处的吸收带属于芳香醚键与脂肪醚键C-O-C的对称与不对称伸缩振动吸收峰.830 cm-1处属于苯环中C-H键的面外弯曲振动,560 cm-1处属于C-C键的面外弯曲振动[30].添加稀土铈改性石墨烯后的水性环氧树脂的特征峰位置未发生明显变化,表明改性石墨烯的引入未改变水性环氧树脂的结构,两者之间属于物理结合[31]. ...

Graphene and graphene derivatives toughening polymers: toward high toughness and strength

1

2019

... 图2为稀土铈改性石墨烯/水性环氧树脂复合涂料本身表面和截面的SEM图.灰黑色为涂料基体,亮白色褶皱颗粒为暴露出的石墨烯颗粒.复合涂料表面由片层状与不规则颗粒组成(图2a和b),片层边缘模糊,断面趋向于一个连续而完整的平面.局部放大区域可见河流状银纹,并且在这些银纹中可以看到连续的片层结构.复合涂料折断后的断面可见部分树脂在受力过程中被拉出基体呈现河流状银纹与连续纵向条纹(图2c和d).这表明石墨烯能够吸附高分子形成高分子包裹的结构单元,提高涂料的致密性,促使涂料体系更为完整.同时使得复合涂料在受力过程中产生大的剪切带,吸收断裂能,提高复合涂料的韧性[32, 33]. ...

Polycarbonate toughening with reduced graphene oxide: toward high toughness, strength and notch resistance

1

2017

... 图2为稀土铈改性石墨烯/水性环氧树脂复合涂料本身表面和截面的SEM图.灰黑色为涂料基体,亮白色褶皱颗粒为暴露出的石墨烯颗粒.复合涂料表面由片层状与不规则颗粒组成(图2a和b),片层边缘模糊,断面趋向于一个连续而完整的平面.局部放大区域可见河流状银纹,并且在这些银纹中可以看到连续的片层结构.复合涂料折断后的断面可见部分树脂在受力过程中被拉出基体呈现河流状银纹与连续纵向条纹(图2c和d).这表明石墨烯能够吸附高分子形成高分子包裹的结构单元,提高涂料的致密性,促使涂料体系更为完整.同时使得复合涂料在受力过程中产生大的剪切带,吸收断裂能,提高复合涂料的韧性[32, 33]. ...

Study on new PPS composite coating preparation and performance

1

2014

... 表1为不同涂装方式制备的稀土铈改性石墨烯/水性环氧树脂复合涂层在钢基体上的各项性能测试结果.可见,喷涂法与刷涂法制备的涂层附着力较优,附着力为0级;滚涂法制备的涂层附着力次之.在一定厚度范围内,涂层厚度增加会延长固化时间,涂层的流平性能越好,涂层内部缺陷数量减少,涂料与基材之间的有效附着点与区域增多,涂层结合强度增加[34].结合截面SEM图可知,喷涂涂层厚度最小,附着力等级较高.对此主要是喷涂过程中,压缩空气使得涂料液滴对基体有冲击力的作用,雾化的涂料液滴与基体的接触更为充分.同时,压缩空气有助于净化基体表面,从而提升涂层附着力.而滚涂与刷涂法中,涂布器对基体施加的力较小,涂料液滴不能充分接触基体,因此附着力等级提升不明显,但与喷涂涂层接近.不同涂装方式制备的涂层硬度均为2H.涂层硬度与基体的交联程度有关,交联度愈高,涂层硬度越高[35].而对于相同成分的涂料,在相同温度、长时间固化后,涂层的交联程度接近.因此不同涂装方式的涂层硬度接近. ...

新型聚苯硫醚复合涂层的制备和性能研究

1

2014

... 表1为不同涂装方式制备的稀土铈改性石墨烯/水性环氧树脂复合涂层在钢基体上的各项性能测试结果.可见,喷涂法与刷涂法制备的涂层附着力较优,附着力为0级;滚涂法制备的涂层附着力次之.在一定厚度范围内,涂层厚度增加会延长固化时间,涂层的流平性能越好,涂层内部缺陷数量减少,涂料与基材之间的有效附着点与区域增多,涂层结合强度增加[34].结合截面SEM图可知,喷涂涂层厚度最小,附着力等级较高.对此主要是喷涂过程中,压缩空气使得涂料液滴对基体有冲击力的作用,雾化的涂料液滴与基体的接触更为充分.同时,压缩空气有助于净化基体表面,从而提升涂层附着力.而滚涂与刷涂法中,涂布器对基体施加的力较小,涂料液滴不能充分接触基体,因此附着力等级提升不明显,但与喷涂涂层接近.不同涂装方式制备的涂层硬度均为2H.涂层硬度与基体的交联程度有关,交联度愈高,涂层硬度越高[35].而对于相同成分的涂料,在相同温度、长时间固化后,涂层的交联程度接近.因此不同涂装方式的涂层硬度接近. ...

Effect of nano-SiO2 on film hardness of flurocarbon coatings

1

2013

... 表1为不同涂装方式制备的稀土铈改性石墨烯/水性环氧树脂复合涂层在钢基体上的各项性能测试结果.可见,喷涂法与刷涂法制备的涂层附着力较优,附着力为0级;滚涂法制备的涂层附着力次之.在一定厚度范围内,涂层厚度增加会延长固化时间,涂层的流平性能越好,涂层内部缺陷数量减少,涂料与基材之间的有效附着点与区域增多,涂层结合强度增加[34].结合截面SEM图可知,喷涂涂层厚度最小,附着力等级较高.对此主要是喷涂过程中,压缩空气使得涂料液滴对基体有冲击力的作用,雾化的涂料液滴与基体的接触更为充分.同时,压缩空气有助于净化基体表面,从而提升涂层附着力.而滚涂与刷涂法中,涂布器对基体施加的力较小,涂料液滴不能充分接触基体,因此附着力等级提升不明显,但与喷涂涂层接近.不同涂装方式制备的涂层硬度均为2H.涂层硬度与基体的交联程度有关,交联度愈高,涂层硬度越高[35].而对于相同成分的涂料,在相同温度、长时间固化后,涂层的交联程度接近.因此不同涂装方式的涂层硬度接近. ...

纳米SiO2对氟碳涂料漆膜硬度的影响

1

2013

... 表1为不同涂装方式制备的稀土铈改性石墨烯/水性环氧树脂复合涂层在钢基体上的各项性能测试结果.可见,喷涂法与刷涂法制备的涂层附着力较优,附着力为0级;滚涂法制备的涂层附着力次之.在一定厚度范围内,涂层厚度增加会延长固化时间,涂层的流平性能越好,涂层内部缺陷数量减少,涂料与基材之间的有效附着点与区域增多,涂层结合强度增加[34].结合截面SEM图可知,喷涂涂层厚度最小,附着力等级较高.对此主要是喷涂过程中,压缩空气使得涂料液滴对基体有冲击力的作用,雾化的涂料液滴与基体的接触更为充分.同时,压缩空气有助于净化基体表面,从而提升涂层附着力.而滚涂与刷涂法中,涂布器对基体施加的力较小,涂料液滴不能充分接触基体,因此附着力等级提升不明显,但与喷涂涂层接近.不同涂装方式制备的涂层硬度均为2H.涂层硬度与基体的交联程度有关,交联度愈高,涂层硬度越高[35].而对于相同成分的涂料,在相同温度、长时间固化后,涂层的交联程度接近.因此不同涂装方式的涂层硬度接近. ...

Surface roughness and contact angle

1

1949

... 如表1所示,采用3种涂装方式制备的涂层的水接触角均小于90°,涂层属于亲水表面.其中,水接触角刷涂<喷涂<滚涂.根据润湿理论,固体表面润湿性与其表面粗糙结构和化学组成有关.对于粗糙表面,一般采用图4中Wenzel模型[36]和Cassie模型[37]进行说明.其中,Wenzel模型更适合于接触角低于90°,表面表现出一定的“粘附性”的材料[38].Cassie模型更适合于接触角高于90°,表面表现出一定“光滑性”的材料.虽然Wenzel模型和Cassie模型分别考虑了液体完全润湿表面和液体完全不润湿表面,是浸润现象的两个极限状态.但实际上,对于粗糙固体表面上的液滴,由于表面的凹凸不平,通常在固液界面之间会截留部分气泡,即会造成部分接触为固-液-气三相接触[39].对此考虑图4c中Wenzel模型和Cassie模型的中间状态[40],接触角公式如 式(2)和(3)所示.此时凹坑的形状对接触角产生较大影响,随着微孔深度的增大,液体的浸润深度增大,润湿性减小. ...

Contact angles

1

1948

... 如表1所示,采用3种涂装方式制备的涂层的水接触角均小于90°,涂层属于亲水表面.其中,水接触角刷涂<喷涂<滚涂.根据润湿理论,固体表面润湿性与其表面粗糙结构和化学组成有关.对于粗糙表面,一般采用图4中Wenzel模型[36]和Cassie模型[37]进行说明.其中,Wenzel模型更适合于接触角低于90°,表面表现出一定的“粘附性”的材料[38].Cassie模型更适合于接触角高于90°,表面表现出一定“光滑性”的材料.虽然Wenzel模型和Cassie模型分别考虑了液体完全润湿表面和液体完全不润湿表面,是浸润现象的两个极限状态.但实际上,对于粗糙固体表面上的液滴,由于表面的凹凸不平,通常在固液界面之间会截留部分气泡,即会造成部分接触为固-液-气三相接触[39].对此考虑图4c中Wenzel模型和Cassie模型的中间状态[40],接触角公式如 式(2)和(3)所示.此时凹坑的形状对接触角产生较大影响,随着微孔深度的增大,液体的浸润深度增大,润湿性减小. ...

Preparation and properties of super hydrophobic and oleophobic polystyrene

1

2021

... 如表1所示,采用3种涂装方式制备的涂层的水接触角均小于90°,涂层属于亲水表面.其中,水接触角刷涂<喷涂<滚涂.根据润湿理论,固体表面润湿性与其表面粗糙结构和化学组成有关.对于粗糙表面,一般采用图4中Wenzel模型[36]和Cassie模型[37]进行说明.其中,Wenzel模型更适合于接触角低于90°,表面表现出一定的“粘附性”的材料[38].Cassie模型更适合于接触角高于90°,表面表现出一定“光滑性”的材料.虽然Wenzel模型和Cassie模型分别考虑了液体完全润湿表面和液体完全不润湿表面,是浸润现象的两个极限状态.但实际上,对于粗糙固体表面上的液滴,由于表面的凹凸不平,通常在固液界面之间会截留部分气泡,即会造成部分接触为固-液-气三相接触[39].对此考虑图4c中Wenzel模型和Cassie模型的中间状态[40],接触角公式如 式(2)和(3)所示.此时凹坑的形状对接触角产生较大影响,随着微孔深度的增大,液体的浸润深度增大,润湿性减小. ...

超疏水疏油聚苯乙烯的制备及性能研究

1

2021

... 如表1所示,采用3种涂装方式制备的涂层的水接触角均小于90°,涂层属于亲水表面.其中,水接触角刷涂<喷涂<滚涂.根据润湿理论,固体表面润湿性与其表面粗糙结构和化学组成有关.对于粗糙表面,一般采用图4中Wenzel模型[36]和Cassie模型[37]进行说明.其中,Wenzel模型更适合于接触角低于90°,表面表现出一定的“粘附性”的材料[38].Cassie模型更适合于接触角高于90°,表面表现出一定“光滑性”的材料.虽然Wenzel模型和Cassie模型分别考虑了液体完全润湿表面和液体完全不润湿表面,是浸润现象的两个极限状态.但实际上,对于粗糙固体表面上的液滴,由于表面的凹凸不平,通常在固液界面之间会截留部分气泡,即会造成部分接触为固-液-气三相接触[39].对此考虑图4c中Wenzel模型和Cassie模型的中间状态[40],接触角公式如 式(2)和(3)所示.此时凹坑的形状对接触角产生较大影响,随着微孔深度的增大,液体的浸润深度增大,润湿性减小. ...

Study of the influence of apparent contact angle on regular rough surface considering liquid wetting properties

1

2007

... 如表1所示,采用3种涂装方式制备的涂层的水接触角均小于90°,涂层属于亲水表面.其中,水接触角刷涂<喷涂<滚涂.根据润湿理论,固体表面润湿性与其表面粗糙结构和化学组成有关.对于粗糙表面,一般采用图4中Wenzel模型[36]和Cassie模型[37]进行说明.其中,Wenzel模型更适合于接触角低于90°,表面表现出一定的“粘附性”的材料[38].Cassie模型更适合于接触角高于90°,表面表现出一定“光滑性”的材料.虽然Wenzel模型和Cassie模型分别考虑了液体完全润湿表面和液体完全不润湿表面,是浸润现象的两个极限状态.但实际上,对于粗糙固体表面上的液滴,由于表面的凹凸不平,通常在固液界面之间会截留部分气泡,即会造成部分接触为固-液-气三相接触[39].对此考虑图4c中Wenzel模型和Cassie模型的中间状态[40],接触角公式如 式(2)和(3)所示.此时凹坑的形状对接触角产生较大影响,随着微孔深度的增大,液体的浸润深度增大,润湿性减小. ...

规则粗糙固体表面液体浸润性对表观接触角影响的研究

1

2007

... 如表1所示,采用3种涂装方式制备的涂层的水接触角均小于90°,涂层属于亲水表面.其中,水接触角刷涂<喷涂<滚涂.根据润湿理论,固体表面润湿性与其表面粗糙结构和化学组成有关.对于粗糙表面,一般采用图4中Wenzel模型[36]和Cassie模型[37]进行说明.其中,Wenzel模型更适合于接触角低于90°,表面表现出一定的“粘附性”的材料[38].Cassie模型更适合于接触角高于90°,表面表现出一定“光滑性”的材料.虽然Wenzel模型和Cassie模型分别考虑了液体完全润湿表面和液体完全不润湿表面,是浸润现象的两个极限状态.但实际上,对于粗糙固体表面上的液滴,由于表面的凹凸不平,通常在固液界面之间会截留部分气泡,即会造成部分接触为固-液-气三相接触[39].对此考虑图4c中Wenzel模型和Cassie模型的中间状态[40],接触角公式如 式(2)和(3)所示.此时凹坑的形状对接触角产生较大影响,随着微孔深度的增大,液体的浸润深度增大,润湿性减小. ...

Contact angle model and wettability on the surfaces with microstructures

1

2009

... 如表1所示,采用3种涂装方式制备的涂层的水接触角均小于90°,涂层属于亲水表面.其中,水接触角刷涂<喷涂<滚涂.根据润湿理论,固体表面润湿性与其表面粗糙结构和化学组成有关.对于粗糙表面,一般采用图4中Wenzel模型[36]和Cassie模型[37]进行说明.其中,Wenzel模型更适合于接触角低于90°,表面表现出一定的“粘附性”的材料[38].Cassie模型更适合于接触角高于90°,表面表现出一定“光滑性”的材料.虽然Wenzel模型和Cassie模型分别考虑了液体完全润湿表面和液体完全不润湿表面,是浸润现象的两个极限状态.但实际上,对于粗糙固体表面上的液滴,由于表面的凹凸不平,通常在固液界面之间会截留部分气泡,即会造成部分接触为固-液-气三相接触[39].对此考虑图4c中Wenzel模型和Cassie模型的中间状态[40],接触角公式如 式(2)和(3)所示.此时凹坑的形状对接触角产生较大影响,随着微孔深度的增大,液体的浸润深度增大,润湿性减小. ...

微观结构表面接触角模型及其润湿性

1

2009

... 如表1所示,采用3种涂装方式制备的涂层的水接触角均小于90°,涂层属于亲水表面.其中,水接触角刷涂<喷涂<滚涂.根据润湿理论,固体表面润湿性与其表面粗糙结构和化学组成有关.对于粗糙表面,一般采用图4中Wenzel模型[36]和Cassie模型[37]进行说明.其中,Wenzel模型更适合于接触角低于90°,表面表现出一定的“粘附性”的材料[38].Cassie模型更适合于接触角高于90°,表面表现出一定“光滑性”的材料.虽然Wenzel模型和Cassie模型分别考虑了液体完全润湿表面和液体完全不润湿表面,是浸润现象的两个极限状态.但实际上,对于粗糙固体表面上的液滴,由于表面的凹凸不平,通常在固液界面之间会截留部分气泡,即会造成部分接触为固-液-气三相接触[39].对此考虑图4c中Wenzel模型和Cassie模型的中间状态[40],接触角公式如 式(2)和(3)所示.此时凹坑的形状对接触角产生较大影响,随着微孔深度的增大,液体的浸润深度增大,润湿性减小. ...

Influencing factors and prediction model of material surface wettability

1

2018

... 图5为3种涂装方式制备的稀土铈改性石墨烯/水性环氧树脂复合涂层在钢基体上的三维图像.可见,复合涂层表面出现由树脂包裹团聚石墨烯引起的粗糙结构(图5a~c),其中喷涂涂层表面突出的颗粒数较多,分布较为均匀,并且颗粒之间分布有微粗糙结构,表面粗糙结构均匀.喷涂涂层表面的石墨烯颗粒高度最高(图5a1~c1),而滚涂法与刷涂法涂层由于涂装方式的差异与涂层厚度增加,涂层表面突出的石墨烯颗粒的数量与高度减小,粗糙结构的均匀性下降.喷涂与滚涂涂层表面的粗糙度更大,凹坑深度更高,水接触角较大.而刷涂涂层的粗糙度下降,但润湿角上升,对此可以通过涂层表面自由能进行解释,结果如表1所示.一般的固体表面能越高,表面亲水性越强[41].不同涂层之间的表面能相近,表面能滚涂<喷涂<刷涂,表面能与涂层润湿性之间表现出一致性. ...

材料表面润湿性的影响因素及预测模型

1

2018

... 图5为3种涂装方式制备的稀土铈改性石墨烯/水性环氧树脂复合涂层在钢基体上的三维图像.可见,复合涂层表面出现由树脂包裹团聚石墨烯引起的粗糙结构(图5a~c),其中喷涂涂层表面突出的颗粒数较多,分布较为均匀,并且颗粒之间分布有微粗糙结构,表面粗糙结构均匀.喷涂涂层表面的石墨烯颗粒高度最高(图5a1~c1),而滚涂法与刷涂法涂层由于涂装方式的差异与涂层厚度增加,涂层表面突出的石墨烯颗粒的数量与高度减小,粗糙结构的均匀性下降.喷涂与滚涂涂层表面的粗糙度更大,凹坑深度更高,水接触角较大.而刷涂涂层的粗糙度下降,但润湿角上升,对此可以通过涂层表面自由能进行解释,结果如表1所示.一般的固体表面能越高,表面亲水性越强[41].不同涂层之间的表面能相近,表面能滚涂<喷涂<刷涂,表面能与涂层润湿性之间表现出一致性. ...

Investigating the effect of SiO2-graphene oxide hybrid as inorganic nanofiller on corrosion protection properties of epoxy coatings

1

2017

... 图6为不同涂装方式制备的环氧涂层与复合涂层在3.5%NaCl溶液中稳定2 h后测试的极化曲线.可见,Q235钢基板的腐蚀电位为-0.596 V,腐蚀电流密度为66.278 μA·cm-2.在涂覆涂层后,试样的自腐蚀电位(Ecorr)正移,自腐蚀电流密度(Icorr)明显下降,即基体的腐蚀倾向与腐蚀速率下降.对不同的涂装方式,在环氧涂层中,自腐蚀电位表现出滚涂<喷涂<刷涂,自腐蚀电流密度喷涂>滚涂>刷涂,对图6按 公式(4)[42]计算得出刷涂涂层的腐蚀速率为1.35 × 10-2 mm/a,远低于喷涂与滚涂层.在复合涂层中,腐蚀电位表现出滚涂<刷涂<喷涂,腐蚀电流密度滚涂>刷涂>喷涂.计算出喷涂涂层的腐蚀速率为1.565 × 10-4 mm/a,远低于滚涂与刷涂涂层.对比两种涂层,相同涂装方式制备的复合涂层的腐蚀电位高于环氧涂层,腐蚀速率下降一个数量级,表明改性石墨烯的引入能够提高涂层的阻隔性能,降低涂层的腐蚀倾向与腐蚀速率,基体金属得到了有效的保护.厚度较小的喷涂复合涂层腐蚀速率远低于较厚的刷涂涂层,且喷涂法制备的复合涂层腐蚀速率下降幅度最高.对此主要是由于喷涂作用下涂层的致密度、涂层与基体的结合力更高,因此对腐蚀介质的阻挡作用更强.其次,可能是由于涂层中的稀土氧化物发挥了缓蚀作用.由图1d可知,GO表面含有大量的活性氧官能团,如羟基,羧酸和环氧基.这些官能团的电离使得氧化石墨烯片带负电,Ce3+会与这些官能团发生静电相互作用,而紧密吸附在GO表面.另外,在制备过程中,GO表面的-OH和-CO等官能团会再次解离,在一定条件下与表面吸附的Ce3+发生反应形成CeO2.而3384 cm-1对应的O-H,1296、1247 cm-1与1117、1037 cm-1对应的C-O-C在复合涂料附近的峰均减弱且产生了红移,说明稀土氧化物(CeO2)活性高、与氧结合能力强,Ce对石墨烯改性时,易和氧元素反应形成配位键,生成新的官能团,而不会破坏石墨烯的sp2结构,降低石墨烯的界面能及表面能(~64.397 mJ·m-2),提高了石墨烯的分散性[43].当腐蚀介质中的H2O、O2和Cl-沿着涂层中的微孔和缺陷逐步向涂层界面扩散渗透时,表面修饰有氧化铈的石墨烯在涂层中能均匀分散在环氧基体中,并与基体紧密结合,作为屏障减缓介质侵入.腐蚀介质要绕过石墨烯填料才能向基体渗透,其渗透路径被延长,从而大幅度降低涂层的腐蚀速率. ...

Preparation and characterization of graphene oxide modified by rare earth

1

2017

... 图6为不同涂装方式制备的环氧涂层与复合涂层在3.5%NaCl溶液中稳定2 h后测试的极化曲线.可见,Q235钢基板的腐蚀电位为-0.596 V,腐蚀电流密度为66.278 μA·cm-2.在涂覆涂层后,试样的自腐蚀电位(Ecorr)正移,自腐蚀电流密度(Icorr)明显下降,即基体的腐蚀倾向与腐蚀速率下降.对不同的涂装方式,在环氧涂层中,自腐蚀电位表现出滚涂<喷涂<刷涂,自腐蚀电流密度喷涂>滚涂>刷涂,对图6按 公式(4)[42]计算得出刷涂涂层的腐蚀速率为1.35 × 10-2 mm/a,远低于喷涂与滚涂层.在复合涂层中,腐蚀电位表现出滚涂<刷涂<喷涂,腐蚀电流密度滚涂>刷涂>喷涂.计算出喷涂涂层的腐蚀速率为1.565 × 10-4 mm/a,远低于滚涂与刷涂涂层.对比两种涂层,相同涂装方式制备的复合涂层的腐蚀电位高于环氧涂层,腐蚀速率下降一个数量级,表明改性石墨烯的引入能够提高涂层的阻隔性能,降低涂层的腐蚀倾向与腐蚀速率,基体金属得到了有效的保护.厚度较小的喷涂复合涂层腐蚀速率远低于较厚的刷涂涂层,且喷涂法制备的复合涂层腐蚀速率下降幅度最高.对此主要是由于喷涂作用下涂层的致密度、涂层与基体的结合力更高,因此对腐蚀介质的阻挡作用更强.其次,可能是由于涂层中的稀土氧化物发挥了缓蚀作用.由图1d可知,GO表面含有大量的活性氧官能团,如羟基,羧酸和环氧基.这些官能团的电离使得氧化石墨烯片带负电,Ce3+会与这些官能团发生静电相互作用,而紧密吸附在GO表面.另外,在制备过程中,GO表面的-OH和-CO等官能团会再次解离,在一定条件下与表面吸附的Ce3+发生反应形成CeO2.而3384 cm-1对应的O-H,1296、1247 cm-1与1117、1037 cm-1对应的C-O-C在复合涂料附近的峰均减弱且产生了红移,说明稀土氧化物(CeO2)活性高、与氧结合能力强,Ce对石墨烯改性时,易和氧元素反应形成配位键,生成新的官能团,而不会破坏石墨烯的sp2结构,降低石墨烯的界面能及表面能(~64.397 mJ·m-2),提高了石墨烯的分散性[43].当腐蚀介质中的H2O、O2和Cl-沿着涂层中的微孔和缺陷逐步向涂层界面扩散渗透时,表面修饰有氧化铈的石墨烯在涂层中能均匀分散在环氧基体中,并与基体紧密结合,作为屏障减缓介质侵入.腐蚀介质要绕过石墨烯填料才能向基体渗透,其渗透路径被延长,从而大幅度降低涂层的腐蚀速率. ...

稀土改性氧化石墨烯的制备及表征

1

2017

... 图6为不同涂装方式制备的环氧涂层与复合涂层在3.5%NaCl溶液中稳定2 h后测试的极化曲线.可见,Q235钢基板的腐蚀电位为-0.596 V,腐蚀电流密度为66.278 μA·cm-2.在涂覆涂层后,试样的自腐蚀电位(Ecorr)正移,自腐蚀电流密度(Icorr)明显下降,即基体的腐蚀倾向与腐蚀速率下降.对不同的涂装方式,在环氧涂层中,自腐蚀电位表现出滚涂<喷涂<刷涂,自腐蚀电流密度喷涂>滚涂>刷涂,对图6按 公式(4)[42]计算得出刷涂涂层的腐蚀速率为1.35 × 10-2 mm/a,远低于喷涂与滚涂层.在复合涂层中,腐蚀电位表现出滚涂<刷涂<喷涂,腐蚀电流密度滚涂>刷涂>喷涂.计算出喷涂涂层的腐蚀速率为1.565 × 10-4 mm/a,远低于滚涂与刷涂涂层.对比两种涂层,相同涂装方式制备的复合涂层的腐蚀电位高于环氧涂层,腐蚀速率下降一个数量级,表明改性石墨烯的引入能够提高涂层的阻隔性能,降低涂层的腐蚀倾向与腐蚀速率,基体金属得到了有效的保护.厚度较小的喷涂复合涂层腐蚀速率远低于较厚的刷涂涂层,且喷涂法制备的复合涂层腐蚀速率下降幅度最高.对此主要是由于喷涂作用下涂层的致密度、涂层与基体的结合力更高,因此对腐蚀介质的阻挡作用更强.其次,可能是由于涂层中的稀土氧化物发挥了缓蚀作用.由图1d可知,GO表面含有大量的活性氧官能团,如羟基,羧酸和环氧基.这些官能团的电离使得氧化石墨烯片带负电,Ce3+会与这些官能团发生静电相互作用,而紧密吸附在GO表面.另外,在制备过程中,GO表面的-OH和-CO等官能团会再次解离,在一定条件下与表面吸附的Ce3+发生反应形成CeO2.而3384 cm-1对应的O-H,1296、1247 cm-1与1117、1037 cm-1对应的C-O-C在复合涂料附近的峰均减弱且产生了红移,说明稀土氧化物(CeO2)活性高、与氧结合能力强,Ce对石墨烯改性时,易和氧元素反应形成配位键,生成新的官能团,而不会破坏石墨烯的sp2结构,降低石墨烯的界面能及表面能(~64.397 mJ·m-2),提高了石墨烯的分散性[43].当腐蚀介质中的H2O、O2和Cl-沿着涂层中的微孔和缺陷逐步向涂层界面扩散渗透时,表面修饰有氧化铈的石墨烯在涂层中能均匀分散在环氧基体中,并与基体紧密结合,作为屏障减缓介质侵入.腐蚀介质要绕过石墨烯填料才能向基体渗透,其渗透路径被延长,从而大幅度降低涂层的腐蚀速率. ...

Mechanical and anticorrosion properties of nanosilica-filled epoxy-resin composite coatings

1

2014

... 图7为不同涂装方式制备的环氧涂层与复合涂层的EIS及其等效电路拟合.从图7a可以看出,采用不同涂装方式制备的环氧涂层与复合涂层的阻抗谱均呈现两个容抗弧,不同涂装方式涂层在高频区的容抗弧大小不同.在环氧涂层中,高频区容抗弧半径喷涂<刷涂<滚涂,在复合涂层中滚涂<刷涂<喷涂.这表明在环氧涂层中滚涂与刷涂涂层的防护性能较好,复合涂层中喷涂涂层的防护性能较好,其中喷涂复合涂层容抗弧半径最大.对Bode图,中低频区(f < 0.1 Hz)反应了涂层的腐蚀过程, = 0.01 Hz值越大,涂层防护性能愈佳[44].从图7b可以看到,不同涂层低频阻抗模量不同.其中,喷涂环氧涂层的阻抗模值最低,喷涂复合涂层的阻抗模值最高,其余涂层的阻抗模值相近.这表明喷涂环氧涂层的防护性能低于滚涂和刷涂涂层,复合涂层中滚涂与刷涂涂层的防护性能低于喷涂涂层.腐蚀介质对涂层的渗透过程可以用等效电路来模拟,一般涂层体系浸泡初期与中期的等效电路如图7c和d所示,其中,Rs为溶液电阻;Rc为涂层电阻,表示涂层中孔隙阻力,涂层孔隙越少或越小,涂层越致密,涂层的保护效率更好.Rct为电极反应的电荷转移电阻,反映涂层下方金属表面对电子转移反应的阻力,其与涂层下的腐蚀速率成反比.Rt = Rc + Rct可反映涂层在腐蚀过程中的保护效果[45].Qc为涂层电容,表征腐蚀介质渗透到涂层中的量,数值越小代表涂层抗介质渗透能力越强,Qdl表征涂层失效面积大小,值越大表明水在涂层中或形成分层的程度越大[46].浸泡初期,随着浸泡时间的增加,电解质溶液逐渐沿着涂层缝隙向钢基底渗透,阻抗谱低频段出现了代表扩散特征的Warburg阻抗[47,48],涂层电阻逐渐减小,涂层电容逐渐增大.原因可能是随着界面区腐蚀反应的不断进行,越来越多的腐蚀产物在界面局部腐蚀区域不断聚集、沉积而使得腐蚀反应为传质过程所控制,代表界面腐蚀反应的低频半圆被Warburg扩散阻抗所掩盖.这段时间的涂层劣化过程可称为基底金属腐蚀发展与涂层失效阶段.表现在Bode图中,就是|Z|-f的曲线向着低频方向移动,曲线逐渐下降.浸泡中期,由于涂层电阻与涂层电容相并联(图7d),两者并联后的复合原件的阻抗值主要显示阻抗值小的元件的阻抗特征,即电容的阻抗.对图7b按Burg公式(见 式(5))[49]进行归一化处理,其中,涂层导纳(Y0)与阻抗(Z)互为倒数,可知喷涂复合涂层具有最高的阻抗模值.利用Zview软件选用图7d等效电路进行拟合,最终涂层电化学参数拟合结果如表2所示.结果表明在环氧涂层中,刷涂与滚涂涂层具有低的涂层电容(~1.231 × 10-5 Ω-1·cm-2·s n )和高的涂层电阻(~5.2906 × 104 Ω·cm2),表明较厚的滚涂与刷涂环氧涂层中腐蚀介质的浸入较少.复合涂层中,喷涂涂层具有低的涂层电容(~1.159 × 10-6 Ω-1·cm-2·s n )和高的涂层电阻(~35.5498 × 104 Ω·cm2).对比环氧涂层与复合涂层,复合涂层电容(Cc)的降低与电阻(Rt)的增加,表明石墨烯的引入能够提高涂层的屏蔽性,减少腐蚀介质的浸入.而其中,喷涂复合涂层的Cc最小,表明喷涂复合涂层中浸入的腐蚀介质最少,涂层的致密性最高.综上所述,喷涂复合涂层防腐性能更优. ...

Corrosion protection and adhesion properties of the epoxy coating applied on the steel substrate pre-treated by a sol-gel based silane coating filled with amino and isocyanate silane functionalized graphene oxide nanosheets

1

2018

... 图7为不同涂装方式制备的环氧涂层与复合涂层的EIS及其等效电路拟合.从图7a可以看出,采用不同涂装方式制备的环氧涂层与复合涂层的阻抗谱均呈现两个容抗弧,不同涂装方式涂层在高频区的容抗弧大小不同.在环氧涂层中,高频区容抗弧半径喷涂<刷涂<滚涂,在复合涂层中滚涂<刷涂<喷涂.这表明在环氧涂层中滚涂与刷涂涂层的防护性能较好,复合涂层中喷涂涂层的防护性能较好,其中喷涂复合涂层容抗弧半径最大.对Bode图,中低频区(f < 0.1 Hz)反应了涂层的腐蚀过程, = 0.01 Hz值越大,涂层防护性能愈佳[44].从图7b可以看到,不同涂层低频阻抗模量不同.其中,喷涂环氧涂层的阻抗模值最低,喷涂复合涂层的阻抗模值最高,其余涂层的阻抗模值相近.这表明喷涂环氧涂层的防护性能低于滚涂和刷涂涂层,复合涂层中滚涂与刷涂涂层的防护性能低于喷涂涂层.腐蚀介质对涂层的渗透过程可以用等效电路来模拟,一般涂层体系浸泡初期与中期的等效电路如图7c和d所示,其中,Rs为溶液电阻;Rc为涂层电阻,表示涂层中孔隙阻力,涂层孔隙越少或越小,涂层越致密,涂层的保护效率更好.Rct为电极反应的电荷转移电阻,反映涂层下方金属表面对电子转移反应的阻力,其与涂层下的腐蚀速率成反比.Rt = Rc + Rct可反映涂层在腐蚀过程中的保护效果[45].Qc为涂层电容,表征腐蚀介质渗透到涂层中的量,数值越小代表涂层抗介质渗透能力越强,Qdl表征涂层失效面积大小,值越大表明水在涂层中或形成分层的程度越大[46].浸泡初期,随着浸泡时间的增加,电解质溶液逐渐沿着涂层缝隙向钢基底渗透,阻抗谱低频段出现了代表扩散特征的Warburg阻抗[47,48],涂层电阻逐渐减小,涂层电容逐渐增大.原因可能是随着界面区腐蚀反应的不断进行,越来越多的腐蚀产物在界面局部腐蚀区域不断聚集、沉积而使得腐蚀反应为传质过程所控制,代表界面腐蚀反应的低频半圆被Warburg扩散阻抗所掩盖.这段时间的涂层劣化过程可称为基底金属腐蚀发展与涂层失效阶段.表现在Bode图中,就是|Z|-f的曲线向着低频方向移动,曲线逐渐下降.浸泡中期,由于涂层电阻与涂层电容相并联(图7d),两者并联后的复合原件的阻抗值主要显示阻抗值小的元件的阻抗特征,即电容的阻抗.对图7b按Burg公式(见 式(5))[49]进行归一化处理,其中,涂层导纳(Y0)与阻抗(Z)互为倒数,可知喷涂复合涂层具有最高的阻抗模值.利用Zview软件选用图7d等效电路进行拟合,最终涂层电化学参数拟合结果如表2所示.结果表明在环氧涂层中,刷涂与滚涂涂层具有低的涂层电容(~1.231 × 10-5 Ω-1·cm-2·s n )和高的涂层电阻(~5.2906 × 104 Ω·cm2),表明较厚的滚涂与刷涂环氧涂层中腐蚀介质的浸入较少.复合涂层中,喷涂涂层具有低的涂层电容(~1.159 × 10-6 Ω-1·cm-2·s n )和高的涂层电阻(~35.5498 × 104 Ω·cm2).对比环氧涂层与复合涂层,复合涂层电容(Cc)的降低与电阻(Rt)的增加,表明石墨烯的引入能够提高涂层的屏蔽性,减少腐蚀介质的浸入.而其中,喷涂复合涂层的Cc最小,表明喷涂复合涂层中浸入的腐蚀介质最少,涂层的致密性最高.综上所述,喷涂复合涂层防腐性能更优. ...

Study on the properties of graphene/expoxy resin anticorrosive coatings

1

2020

... 图7为不同涂装方式制备的环氧涂层与复合涂层的EIS及其等效电路拟合.从图7a可以看出,采用不同涂装方式制备的环氧涂层与复合涂层的阻抗谱均呈现两个容抗弧,不同涂装方式涂层在高频区的容抗弧大小不同.在环氧涂层中,高频区容抗弧半径喷涂<刷涂<滚涂,在复合涂层中滚涂<刷涂<喷涂.这表明在环氧涂层中滚涂与刷涂涂层的防护性能较好,复合涂层中喷涂涂层的防护性能较好,其中喷涂复合涂层容抗弧半径最大.对Bode图,中低频区(f < 0.1 Hz)反应了涂层的腐蚀过程, = 0.01 Hz值越大,涂层防护性能愈佳[44].从图7b可以看到,不同涂层低频阻抗模量不同.其中,喷涂环氧涂层的阻抗模值最低,喷涂复合涂层的阻抗模值最高,其余涂层的阻抗模值相近.这表明喷涂环氧涂层的防护性能低于滚涂和刷涂涂层,复合涂层中滚涂与刷涂涂层的防护性能低于喷涂涂层.腐蚀介质对涂层的渗透过程可以用等效电路来模拟,一般涂层体系浸泡初期与中期的等效电路如图7c和d所示,其中,Rs为溶液电阻;Rc为涂层电阻,表示涂层中孔隙阻力,涂层孔隙越少或越小,涂层越致密,涂层的保护效率更好.Rct为电极反应的电荷转移电阻,反映涂层下方金属表面对电子转移反应的阻力,其与涂层下的腐蚀速率成反比.Rt = Rc + Rct可反映涂层在腐蚀过程中的保护效果[45].Qc为涂层电容,表征腐蚀介质渗透到涂层中的量,数值越小代表涂层抗介质渗透能力越强,Qdl表征涂层失效面积大小,值越大表明水在涂层中或形成分层的程度越大[46].浸泡初期,随着浸泡时间的增加,电解质溶液逐渐沿着涂层缝隙向钢基底渗透,阻抗谱低频段出现了代表扩散特征的Warburg阻抗[47,48],涂层电阻逐渐减小,涂层电容逐渐增大.原因可能是随着界面区腐蚀反应的不断进行,越来越多的腐蚀产物在界面局部腐蚀区域不断聚集、沉积而使得腐蚀反应为传质过程所控制,代表界面腐蚀反应的低频半圆被Warburg扩散阻抗所掩盖.这段时间的涂层劣化过程可称为基底金属腐蚀发展与涂层失效阶段.表现在Bode图中,就是|Z|-f的曲线向着低频方向移动,曲线逐渐下降.浸泡中期,由于涂层电阻与涂层电容相并联(图7d),两者并联后的复合原件的阻抗值主要显示阻抗值小的元件的阻抗特征,即电容的阻抗.对图7b按Burg公式(见 式(5))[49]进行归一化处理,其中,涂层导纳(Y0)与阻抗(Z)互为倒数,可知喷涂复合涂层具有最高的阻抗模值.利用Zview软件选用图7d等效电路进行拟合,最终涂层电化学参数拟合结果如表2所示.结果表明在环氧涂层中,刷涂与滚涂涂层具有低的涂层电容(~1.231 × 10-5 Ω-1·cm-2·s n )和高的涂层电阻(~5.2906 × 104 Ω·cm2),表明较厚的滚涂与刷涂环氧涂层中腐蚀介质的浸入较少.复合涂层中,喷涂涂层具有低的涂层电容(~1.159 × 10-6 Ω-1·cm-2·s n )和高的涂层电阻(~35.5498 × 104 Ω·cm2).对比环氧涂层与复合涂层,复合涂层电容(Cc)的降低与电阻(Rt)的增加,表明石墨烯的引入能够提高涂层的屏蔽性,减少腐蚀介质的浸入.而其中,喷涂复合涂层的Cc最小,表明喷涂复合涂层中浸入的腐蚀介质最少,涂层的致密性最高.综上所述,喷涂复合涂层防腐性能更优. ...

石墨烯/环氧树脂防腐涂料性能研究

1

2020

... 图7为不同涂装方式制备的环氧涂层与复合涂层的EIS及其等效电路拟合.从图7a可以看出,采用不同涂装方式制备的环氧涂层与复合涂层的阻抗谱均呈现两个容抗弧,不同涂装方式涂层在高频区的容抗弧大小不同.在环氧涂层中,高频区容抗弧半径喷涂<刷涂<滚涂,在复合涂层中滚涂<刷涂<喷涂.这表明在环氧涂层中滚涂与刷涂涂层的防护性能较好,复合涂层中喷涂涂层的防护性能较好,其中喷涂复合涂层容抗弧半径最大.对Bode图,中低频区(f < 0.1 Hz)反应了涂层的腐蚀过程, = 0.01 Hz值越大,涂层防护性能愈佳[44].从图7b可以看到,不同涂层低频阻抗模量不同.其中,喷涂环氧涂层的阻抗模值最低,喷涂复合涂层的阻抗模值最高,其余涂层的阻抗模值相近.这表明喷涂环氧涂层的防护性能低于滚涂和刷涂涂层,复合涂层中滚涂与刷涂涂层的防护性能低于喷涂涂层.腐蚀介质对涂层的渗透过程可以用等效电路来模拟,一般涂层体系浸泡初期与中期的等效电路如图7c和d所示,其中,Rs为溶液电阻;Rc为涂层电阻,表示涂层中孔隙阻力,涂层孔隙越少或越小,涂层越致密,涂层的保护效率更好.Rct为电极反应的电荷转移电阻,反映涂层下方金属表面对电子转移反应的阻力,其与涂层下的腐蚀速率成反比.Rt = Rc + Rct可反映涂层在腐蚀过程中的保护效果[45].Qc为涂层电容,表征腐蚀介质渗透到涂层中的量,数值越小代表涂层抗介质渗透能力越强,Qdl表征涂层失效面积大小,值越大表明水在涂层中或形成分层的程度越大[46].浸泡初期,随着浸泡时间的增加,电解质溶液逐渐沿着涂层缝隙向钢基底渗透,阻抗谱低频段出现了代表扩散特征的Warburg阻抗[47,48],涂层电阻逐渐减小,涂层电容逐渐增大.原因可能是随着界面区腐蚀反应的不断进行,越来越多的腐蚀产物在界面局部腐蚀区域不断聚集、沉积而使得腐蚀反应为传质过程所控制,代表界面腐蚀反应的低频半圆被Warburg扩散阻抗所掩盖.这段时间的涂层劣化过程可称为基底金属腐蚀发展与涂层失效阶段.表现在Bode图中,就是|Z|-f的曲线向着低频方向移动,曲线逐渐下降.浸泡中期,由于涂层电阻与涂层电容相并联(图7d),两者并联后的复合原件的阻抗值主要显示阻抗值小的元件的阻抗特征,即电容的阻抗.对图7b按Burg公式(见 式(5))[49]进行归一化处理,其中,涂层导纳(Y0)与阻抗(Z)互为倒数,可知喷涂复合涂层具有最高的阻抗模值.利用Zview软件选用图7d等效电路进行拟合,最终涂层电化学参数拟合结果如表2所示.结果表明在环氧涂层中,刷涂与滚涂涂层具有低的涂层电容(~1.231 × 10-5 Ω-1·cm-2·s n )和高的涂层电阻(~5.2906 × 104 Ω·cm2),表明较厚的滚涂与刷涂环氧涂层中腐蚀介质的浸入较少.复合涂层中,喷涂涂层具有低的涂层电容(~1.159 × 10-6 Ω-1·cm-2·s n )和高的涂层电阻(~35.5498 × 104 Ω·cm2).对比环氧涂层与复合涂层,复合涂层电容(Cc)的降低与电阻(Rt)的增加,表明石墨烯的引入能够提高涂层的屏蔽性,减少腐蚀介质的浸入.而其中,喷涂复合涂层的Cc最小,表明喷涂复合涂层中浸入的腐蚀介质最少,涂层的致密性最高.综上所述,喷涂复合涂层防腐性能更优. ...

Electrochemical processes in all-solid-state Li-S batteries studied by electrochemical impedance spectroscopy

1

2021

... 图7为不同涂装方式制备的环氧涂层与复合涂层的EIS及其等效电路拟合.从图7a可以看出,采用不同涂装方式制备的环氧涂层与复合涂层的阻抗谱均呈现两个容抗弧,不同涂装方式涂层在高频区的容抗弧大小不同.在环氧涂层中,高频区容抗弧半径喷涂<刷涂<滚涂,在复合涂层中滚涂<刷涂<喷涂.这表明在环氧涂层中滚涂与刷涂涂层的防护性能较好,复合涂层中喷涂涂层的防护性能较好,其中喷涂复合涂层容抗弧半径最大.对Bode图,中低频区(f < 0.1 Hz)反应了涂层的腐蚀过程, = 0.01 Hz值越大,涂层防护性能愈佳[44].从图7b可以看到,不同涂层低频阻抗模量不同.其中,喷涂环氧涂层的阻抗模值最低,喷涂复合涂层的阻抗模值最高,其余涂层的阻抗模值相近.这表明喷涂环氧涂层的防护性能低于滚涂和刷涂涂层,复合涂层中滚涂与刷涂涂层的防护性能低于喷涂涂层.腐蚀介质对涂层的渗透过程可以用等效电路来模拟,一般涂层体系浸泡初期与中期的等效电路如图7c和d所示,其中,Rs为溶液电阻;Rc为涂层电阻,表示涂层中孔隙阻力,涂层孔隙越少或越小,涂层越致密,涂层的保护效率更好.Rct为电极反应的电荷转移电阻,反映涂层下方金属表面对电子转移反应的阻力,其与涂层下的腐蚀速率成反比.Rt = Rc + Rct可反映涂层在腐蚀过程中的保护效果[45].Qc为涂层电容,表征腐蚀介质渗透到涂层中的量,数值越小代表涂层抗介质渗透能力越强,Qdl表征涂层失效面积大小,值越大表明水在涂层中或形成分层的程度越大[46].浸泡初期,随着浸泡时间的增加,电解质溶液逐渐沿着涂层缝隙向钢基底渗透,阻抗谱低频段出现了代表扩散特征的Warburg阻抗[47,48],涂层电阻逐渐减小,涂层电容逐渐增大.原因可能是随着界面区腐蚀反应的不断进行,越来越多的腐蚀产物在界面局部腐蚀区域不断聚集、沉积而使得腐蚀反应为传质过程所控制,代表界面腐蚀反应的低频半圆被Warburg扩散阻抗所掩盖.这段时间的涂层劣化过程可称为基底金属腐蚀发展与涂层失效阶段.表现在Bode图中,就是|Z|-f的曲线向着低频方向移动,曲线逐渐下降.浸泡中期,由于涂层电阻与涂层电容相并联(图7d),两者并联后的复合原件的阻抗值主要显示阻抗值小的元件的阻抗特征,即电容的阻抗.对图7b按Burg公式(见 式(5))[49]进行归一化处理,其中,涂层导纳(Y0)与阻抗(Z)互为倒数,可知喷涂复合涂层具有最高的阻抗模值.利用Zview软件选用图7d等效电路进行拟合,最终涂层电化学参数拟合结果如表2所示.结果表明在环氧涂层中,刷涂与滚涂涂层具有低的涂层电容(~1.231 × 10-5 Ω-1·cm-2·s n )和高的涂层电阻(~5.2906 × 104 Ω·cm2),表明较厚的滚涂与刷涂环氧涂层中腐蚀介质的浸入较少.复合涂层中,喷涂涂层具有低的涂层电容(~1.159 × 10-6 Ω-1·cm-2·s n )和高的涂层电阻(~35.5498 × 104 Ω·cm2).对比环氧涂层与复合涂层,复合涂层电容(Cc)的降低与电阻(Rt)的增加,表明石墨烯的引入能够提高涂层的屏蔽性,减少腐蚀介质的浸入.而其中,喷涂复合涂层的Cc最小,表明喷涂复合涂层中浸入的腐蚀介质最少,涂层的致密性最高.综上所述,喷涂复合涂层防腐性能更优. ...

Effect of temperature on corrosion behavior of X80 pipeline steel in acidic soil

1

2015

... 图7为不同涂装方式制备的环氧涂层与复合涂层的EIS及其等效电路拟合.从图7a可以看出,采用不同涂装方式制备的环氧涂层与复合涂层的阻抗谱均呈现两个容抗弧,不同涂装方式涂层在高频区的容抗弧大小不同.在环氧涂层中,高频区容抗弧半径喷涂<刷涂<滚涂,在复合涂层中滚涂<刷涂<喷涂.这表明在环氧涂层中滚涂与刷涂涂层的防护性能较好,复合涂层中喷涂涂层的防护性能较好,其中喷涂复合涂层容抗弧半径最大.对Bode图,中低频区(f < 0.1 Hz)反应了涂层的腐蚀过程, = 0.01 Hz值越大,涂层防护性能愈佳[44].从图7b可以看到,不同涂层低频阻抗模量不同.其中,喷涂环氧涂层的阻抗模值最低,喷涂复合涂层的阻抗模值最高,其余涂层的阻抗模值相近.这表明喷涂环氧涂层的防护性能低于滚涂和刷涂涂层,复合涂层中滚涂与刷涂涂层的防护性能低于喷涂涂层.腐蚀介质对涂层的渗透过程可以用等效电路来模拟,一般涂层体系浸泡初期与中期的等效电路如图7c和d所示,其中,Rs为溶液电阻;Rc为涂层电阻,表示涂层中孔隙阻力,涂层孔隙越少或越小,涂层越致密,涂层的保护效率更好.Rct为电极反应的电荷转移电阻,反映涂层下方金属表面对电子转移反应的阻力,其与涂层下的腐蚀速率成反比.Rt = Rc + Rct可反映涂层在腐蚀过程中的保护效果[45].Qc为涂层电容,表征腐蚀介质渗透到涂层中的量,数值越小代表涂层抗介质渗透能力越强,Qdl表征涂层失效面积大小,值越大表明水在涂层中或形成分层的程度越大[46].浸泡初期,随着浸泡时间的增加,电解质溶液逐渐沿着涂层缝隙向钢基底渗透,阻抗谱低频段出现了代表扩散特征的Warburg阻抗[47,48],涂层电阻逐渐减小,涂层电容逐渐增大.原因可能是随着界面区腐蚀反应的不断进行,越来越多的腐蚀产物在界面局部腐蚀区域不断聚集、沉积而使得腐蚀反应为传质过程所控制,代表界面腐蚀反应的低频半圆被Warburg扩散阻抗所掩盖.这段时间的涂层劣化过程可称为基底金属腐蚀发展与涂层失效阶段.表现在Bode图中,就是|Z|-f的曲线向着低频方向移动,曲线逐渐下降.浸泡中期,由于涂层电阻与涂层电容相并联(图7d),两者并联后的复合原件的阻抗值主要显示阻抗值小的元件的阻抗特征,即电容的阻抗.对图7b按Burg公式(见 式(5))[49]进行归一化处理,其中,涂层导纳(Y0)与阻抗(Z)互为倒数,可知喷涂复合涂层具有最高的阻抗模值.利用Zview软件选用图7d等效电路进行拟合,最终涂层电化学参数拟合结果如表2所示.结果表明在环氧涂层中,刷涂与滚涂涂层具有低的涂层电容(~1.231 × 10-5 Ω-1·cm-2·s n )和高的涂层电阻(~5.2906 × 104 Ω·cm2),表明较厚的滚涂与刷涂环氧涂层中腐蚀介质的浸入较少.复合涂层中,喷涂涂层具有低的涂层电容(~1.159 × 10-6 Ω-1·cm-2·s n )和高的涂层电阻(~35.5498 × 104 Ω·cm2).对比环氧涂层与复合涂层,复合涂层电容(Cc)的降低与电阻(Rt)的增加,表明石墨烯的引入能够提高涂层的屏蔽性,减少腐蚀介质的浸入.而其中,喷涂复合涂层的Cc最小,表明喷涂复合涂层中浸入的腐蚀介质最少,涂层的致密性最高.综上所述,喷涂复合涂层防腐性能更优. ...

温度对X80管线钢酸性红壤腐蚀行为的影响

1

2015

... 图7为不同涂装方式制备的环氧涂层与复合涂层的EIS及其等效电路拟合.从图7a可以看出,采用不同涂装方式制备的环氧涂层与复合涂层的阻抗谱均呈现两个容抗弧,不同涂装方式涂层在高频区的容抗弧大小不同.在环氧涂层中,高频区容抗弧半径喷涂<刷涂<滚涂,在复合涂层中滚涂<刷涂<喷涂.这表明在环氧涂层中滚涂与刷涂涂层的防护性能较好,复合涂层中喷涂涂层的防护性能较好,其中喷涂复合涂层容抗弧半径最大.对Bode图,中低频区(f < 0.1 Hz)反应了涂层的腐蚀过程, = 0.01 Hz值越大,涂层防护性能愈佳[44].从图7b可以看到,不同涂层低频阻抗模量不同.其中,喷涂环氧涂层的阻抗模值最低,喷涂复合涂层的阻抗模值最高,其余涂层的阻抗模值相近.这表明喷涂环氧涂层的防护性能低于滚涂和刷涂涂层,复合涂层中滚涂与刷涂涂层的防护性能低于喷涂涂层.腐蚀介质对涂层的渗透过程可以用等效电路来模拟,一般涂层体系浸泡初期与中期的等效电路如图7c和d所示,其中,Rs为溶液电阻;Rc为涂层电阻,表示涂层中孔隙阻力,涂层孔隙越少或越小,涂层越致密,涂层的保护效率更好.Rct为电极反应的电荷转移电阻,反映涂层下方金属表面对电子转移反应的阻力,其与涂层下的腐蚀速率成反比.Rt = Rc + Rct可反映涂层在腐蚀过程中的保护效果[45].Qc为涂层电容,表征腐蚀介质渗透到涂层中的量,数值越小代表涂层抗介质渗透能力越强,Qdl表征涂层失效面积大小,值越大表明水在涂层中或形成分层的程度越大[46].浸泡初期,随着浸泡时间的增加,电解质溶液逐渐沿着涂层缝隙向钢基底渗透,阻抗谱低频段出现了代表扩散特征的Warburg阻抗[47,48],涂层电阻逐渐减小,涂层电容逐渐增大.原因可能是随着界面区腐蚀反应的不断进行,越来越多的腐蚀产物在界面局部腐蚀区域不断聚集、沉积而使得腐蚀反应为传质过程所控制,代表界面腐蚀反应的低频半圆被Warburg扩散阻抗所掩盖.这段时间的涂层劣化过程可称为基底金属腐蚀发展与涂层失效阶段.表现在Bode图中,就是|Z|-f的曲线向着低频方向移动,曲线逐渐下降.浸泡中期,由于涂层电阻与涂层电容相并联(图7d),两者并联后的复合原件的阻抗值主要显示阻抗值小的元件的阻抗特征,即电容的阻抗.对图7b按Burg公式(见 式(5))[49]进行归一化处理,其中,涂层导纳(Y0)与阻抗(Z)互为倒数,可知喷涂复合涂层具有最高的阻抗模值.利用Zview软件选用图7d等效电路进行拟合,最终涂层电化学参数拟合结果如表2所示.结果表明在环氧涂层中,刷涂与滚涂涂层具有低的涂层电容(~1.231 × 10-5 Ω-1·cm-2·s n )和高的涂层电阻(~5.2906 × 104 Ω·cm2),表明较厚的滚涂与刷涂环氧涂层中腐蚀介质的浸入较少.复合涂层中,喷涂涂层具有低的涂层电容(~1.159 × 10-6 Ω-1·cm-2·s n )和高的涂层电阻(~35.5498 × 104 Ω·cm2).对比环氧涂层与复合涂层,复合涂层电容(Cc)的降低与电阻(Rt)的增加,表明石墨烯的引入能够提高涂层的屏蔽性,减少腐蚀介质的浸入.而其中,喷涂复合涂层的Cc最小,表明喷涂复合涂层中浸入的腐蚀介质最少,涂层的致密性最高.综上所述,喷涂复合涂层防腐性能更优. ...

Determination of effective capacitance and film thickness from constant-phase-element parameters

1

2010

... 图7为不同涂装方式制备的环氧涂层与复合涂层的EIS及其等效电路拟合.从图7a可以看出,采用不同涂装方式制备的环氧涂层与复合涂层的阻抗谱均呈现两个容抗弧,不同涂装方式涂层在高频区的容抗弧大小不同.在环氧涂层中,高频区容抗弧半径喷涂<刷涂<滚涂,在复合涂层中滚涂<刷涂<喷涂.这表明在环氧涂层中滚涂与刷涂涂层的防护性能较好,复合涂层中喷涂涂层的防护性能较好,其中喷涂复合涂层容抗弧半径最大.对Bode图,中低频区(f < 0.1 Hz)反应了涂层的腐蚀过程, = 0.01 Hz值越大,涂层防护性能愈佳[44].从图7b可以看到,不同涂层低频阻抗模量不同.其中,喷涂环氧涂层的阻抗模值最低,喷涂复合涂层的阻抗模值最高,其余涂层的阻抗模值相近.这表明喷涂环氧涂层的防护性能低于滚涂和刷涂涂层,复合涂层中滚涂与刷涂涂层的防护性能低于喷涂涂层.腐蚀介质对涂层的渗透过程可以用等效电路来模拟,一般涂层体系浸泡初期与中期的等效电路如图7c和d所示,其中,Rs为溶液电阻;Rc为涂层电阻,表示涂层中孔隙阻力,涂层孔隙越少或越小,涂层越致密,涂层的保护效率更好.Rct为电极反应的电荷转移电阻,反映涂层下方金属表面对电子转移反应的阻力,其与涂层下的腐蚀速率成反比.Rt = Rc + Rct可反映涂层在腐蚀过程中的保护效果[45].Qc为涂层电容,表征腐蚀介质渗透到涂层中的量,数值越小代表涂层抗介质渗透能力越强,Qdl表征涂层失效面积大小,值越大表明水在涂层中或形成分层的程度越大[46].浸泡初期,随着浸泡时间的增加,电解质溶液逐渐沿着涂层缝隙向钢基底渗透,阻抗谱低频段出现了代表扩散特征的Warburg阻抗[47,48],涂层电阻逐渐减小,涂层电容逐渐增大.原因可能是随着界面区腐蚀反应的不断进行,越来越多的腐蚀产物在界面局部腐蚀区域不断聚集、沉积而使得腐蚀反应为传质过程所控制,代表界面腐蚀反应的低频半圆被Warburg扩散阻抗所掩盖.这段时间的涂层劣化过程可称为基底金属腐蚀发展与涂层失效阶段.表现在Bode图中,就是|Z|-f的曲线向着低频方向移动,曲线逐渐下降.浸泡中期,由于涂层电阻与涂层电容相并联(图7d),两者并联后的复合原件的阻抗值主要显示阻抗值小的元件的阻抗特征,即电容的阻抗.对图7b按Burg公式(见 式(5))[49]进行归一化处理,其中,涂层导纳(Y0)与阻抗(Z)互为倒数,可知喷涂复合涂层具有最高的阻抗模值.利用Zview软件选用图7d等效电路进行拟合,最终涂层电化学参数拟合结果如表2所示.结果表明在环氧涂层中,刷涂与滚涂涂层具有低的涂层电容(~1.231 × 10-5 Ω-1·cm-2·s n )和高的涂层电阻(~5.2906 × 104 Ω·cm2),表明较厚的滚涂与刷涂环氧涂层中腐蚀介质的浸入较少.复合涂层中,喷涂涂层具有低的涂层电容(~1.159 × 10-6 Ω-1·cm-2·s n )和高的涂层电阻(~35.5498 × 104 Ω·cm2).对比环氧涂层与复合涂层,复合涂层电容(Cc)的降低与电阻(Rt)的增加,表明石墨烯的引入能够提高涂层的屏蔽性,减少腐蚀介质的浸入.而其中,喷涂复合涂层的Cc最小,表明喷涂复合涂层中浸入的腐蚀介质最少,涂层的致密性最高.综上所述,喷涂复合涂层防腐性能更优. ...