管道对于海洋油气生产和运输至关重要[1]。为了提高运行效率,高强度钢 (如X80钢) 已开始用于海洋环境[2]。腐蚀是导致管道失效的主要机制[3],尤其是在海洋环境中,温度、溶解氧和盐度等多种因素都会影响管道腐蚀[4,5]。有机涂层通过将金属表面与腐蚀环境分离,已广泛应用于金属材料的防腐。环氧树脂 (EP) 涂层因其优异的力学性能、耐化学性、与金属的附着力强和成本低等特点,是目前应用最广泛、最有效的防腐涂层之一[6~8]。然而,在涂层固化过程中,溶剂的蒸发会导致微孔的形成,这可能会降低涂层的耐蚀性,导致涂层失效[9]。因此,提高涂层的耐蚀性具有重要意义。此外,由于管道钢的使用环境,用于管道钢的涂层的摩擦磨损性能也十分重要。

目前,已经开发并使用了大量填料和添加剂来增强有机涂料的耐腐蚀性和抗老化性。其中,金属氧化物纳米颗粒和碳纳米材料由于其优异的物理、化学和力学性能而引起了广泛的兴趣[10~12]。许多纳米颗粒,如Al2O3、TiO2、Fe2O3和CeO2等,已被广泛研究作为有机涂层的腐蚀屏障和抑制剂[13~16]。Fedel等[17]研究表明在低碳钢表面沉积纳米CeO2,会显著提高其腐蚀电位和阻抗。Xavier[18]将纳米CeO2颗粒添加到EP中,研究表明CeO2可以增强涂层的阻隔保护性能。碳纳米管作为典型的碳纳米材料之一,具有高纵横比、中空结构和良好的力学稳定性等特点[19~21]。Cui等[22]采用聚 (2-丁基苯胺) 通过非共价功能化将多壁碳纳米管(MWCNTs)分散到环氧涂层中,对复合涂层的腐蚀和摩擦学性能有明显影响。Khun等[23]研究表明添加MWCNTs可以降低复合涂层的摩擦系数。

本研究采用铈盐处理MWCNTs,制备纳米CeO2@MWCNTs粉体。为了研究CeO2@MWCNTs对EP涂层的影响,在EP涂层中加入CeO2@MWCNTs,制备了不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层,并均匀涂覆在X80钢上。系统研究了CeO2@MWCNTs/EP复合涂层的电化学腐蚀行为和摩擦磨损性能。

1 实验方法

实验所用钢材为X80高强度管线钢,试样尺寸为10 mm×10 mm×3 mm,使用800目的SiC砂纸打磨至表面平整,然后用去离子水和无水乙醇对试样进行清洗,吹干备用。

将0.3 g的MWCNTs置于烧杯中,加入20 mL无水乙醇,滴加一定量的氨水,调节体系的pH为8~9,超声波分散1 h;然后称取2 g的Ce(NO3)3·6H2O溶于20 mL无水乙醇中,在超声的同时将Ce(NO3)3·6H2O溶液缓慢滴加入上述混合液中,再超声波分散3 h;反应结束后抽滤,再用丙酮洗涤两次;将其置于烘箱中,80 °C下干燥2 h后研磨至粉末状,即得到CeO2包覆的MWCNTs (CeO2@MWCNTs)。

取10 g EP,水浴温度80 ℃;按质量分数为0.1%、0.5%和1%称取CeO2@MWCNTs于烧杯中,加入一定量丙酮溶剂,超声波分散0.5 h;然后缓慢加入到EP中,机械揽拌1 h,之后超声波分散至丙酮挥发完;关闭超声,加入邻苯二甲酸二丁酯、乙二胺、流平剂 (二甲基硅油),机械揽拌0.5 h;采用旋涂机在X80钢上制备CeO2@MWCNTs/EP复合涂层,室温干燥固化。

采用透射电镜 (TEM,FEI Tecnai G2 f20 s-twin) 对包覆前后的MWCNTs进行表征;利用X射线光电子能谱 (XPS,Thermo Fisher Scientific) 对粉末进行分析,数据以C 1s结合能取284.8 eV进行校准,利用XPS peak4.1进行分峰拟合;红外光谱 (FT-IR,EQUINOX-55)测试用溴化钾压片法;利用扫描电镜 (SEM,COXEM EM-30AX)观察和分析形貌,并用EDS进行元素分析,采集时间均为30 s;利用接触角分析仪 (Powereach) 对试样的浸润性进行表征,测试液体为3.5% (质量分数) NaCl溶液;利用HVT-10COA型显微硬度测试分析系统,测试复合涂层的硬度,实验力为 0.5 N,实验力保荷时间为10 s,每个样品上压痕为5个,然后取其平均值。

电化学测试使用多通道电化学工作站 (Ivium-n-Stat),测试溶液为3.5%NaCl溶液。Pt片为对电极、Ag/AgCl电极为参比电极。首先,对试样的开路电位 (EOCP) 跟踪30 min直至其达到稳定;接着,以EOCP作为电化学阻抗谱 (EIS) 的测试电位进行测试,振幅为10 mV,测试的频率为105~10-2 Hz,在测试完成之后使用ZSimpWin软件对数据进行拟合及分析。最后,测试动电位极化曲线,测试范围为EOCP-0.25 V~EOCP+0.50 V,扫描速率为0.3 mV/s。

在干摩擦条件下,对不同CeO2@MWCNTs添加量的复合涂层进行了摩擦磨损测试。滑动摩擦副为氧化铝,载荷为2 N,频率为2 Hz,时间为20 min;测试结束后,用白光干涉仪观察复合涂层的表面形貌,并根据下式计算涂层的体积磨损率[24]:

其中,K为磨损率,mm3/(N∙m),V是磨损体积,N是法向载荷,L为摩擦距离。

2 结果与讨论

2.1 MWCNTs与CeO2@MWCNTs的微观结构

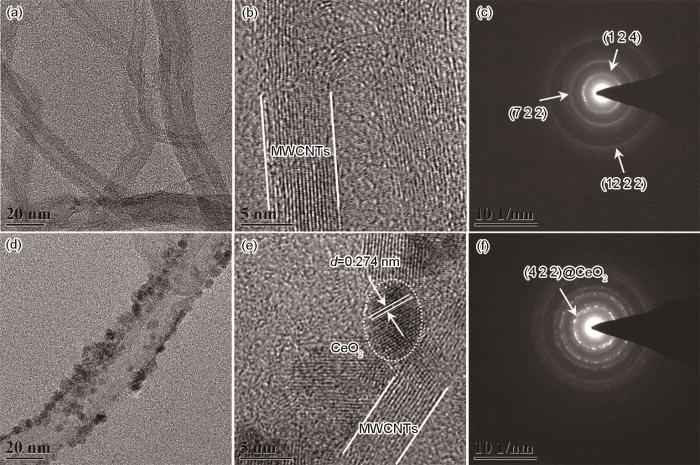

图1

图1

MWCNTs与CeO2@MWCNTs的微观形貌和能谱结果

Fig.1

Morphologies (a, b) and EDS results (c, d) of MWCNTs (a, c) and CeO2@MWCNTs (b, d)

图2

图2

MWCNTs与CeO2@MWCNTs的TEM分析结果

Fig.2

TEM (a, d), HRTEM images (b, e) and SAED results (c, f) of MWCNTs (a-c) and CeO2@MWCNTs (d-f)

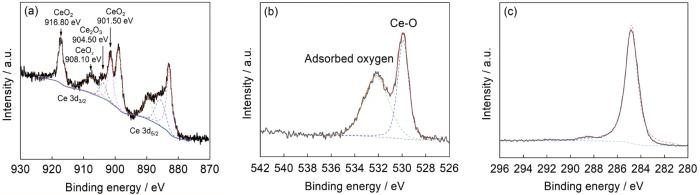

图3为经铈盐处理的MWCNTs中Ce、O和C的精细谱图。885.90 和904.50 eV处的峰值对应Ce2O3[25]。而882.90、889.50、898.40、901.50、908.10和916.80 eV的峰值主要对应CeO2[25~27]。通过对图3a积分峰面积进行半定量分析,CeO2的相对含量约为81.7%。在图3b中,529.80 eV处的结合能对应Ce-O键[26],532.10 eV处的峰值为吸附氧[28]。XPS光谱可以确定图2d所示的纳米颗粒为氧化铈,主要以CeO2的形式存在,即经铈盐处理MWCNTs后,成功制备了CeO2@MWCNTs。此外,在图3c所示的C的窄谱中只出现一个峰,C与Ce (或O) 之间没有键合作用,因此,在CeO2@MWCNTs中CeO2与MWCNTS之间的相互作用是物理吸附,在MWCNTs上形成的CeO2纳米颗粒为5~10 nm的纳米晶。

图3

图3

CeO2@MWCNTs的XPS谱

Fig.3

XPS spectra of CeO2@MWCNTs: (a) Ce 3d, (b) O 1s, (c) C 1s

2.2 CeO2@MWCNTs/EP复合涂层的形貌

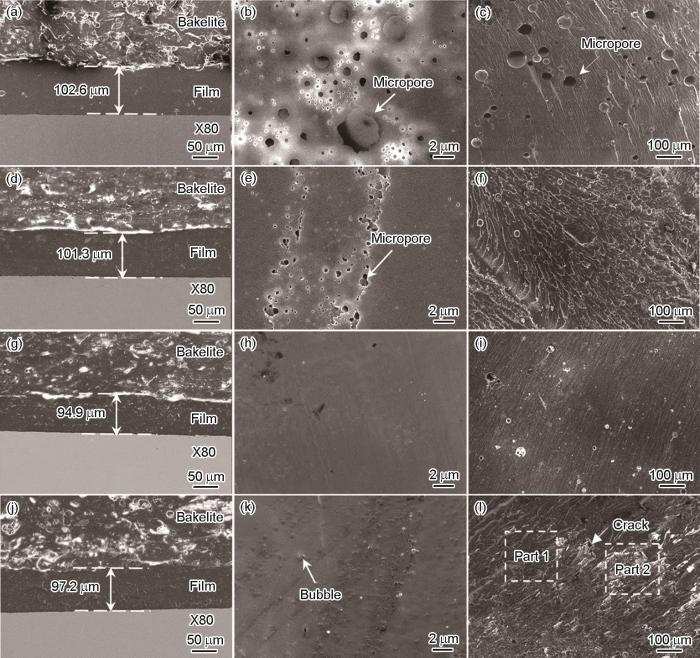

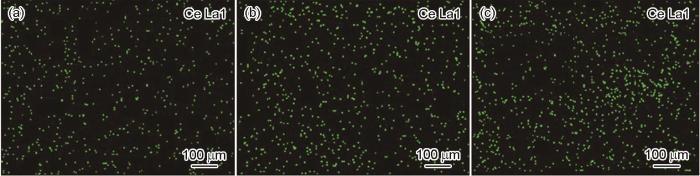

图4为不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的截面、表面和断口形貌 (EP涂层是0% CeO2@MWCNTs/EP涂层)。4种涂层的厚度基本相同,约为99.0±3.6 μm。EP涂层中产生微孔 (图4b和c),这是由于EP固化和溶剂蒸发引起的。涂层中存在的微孔不利于涂层的耐蚀性,因为微孔提供了腐蚀介质穿透涂层的通道。随着CeO2@MWCNTs加入量的增加,涂层中微孔的大小和数量都在减少。当CeO2@MWCNTs的含量增加到0.5%时,涂层中的微孔几乎完全消失。结果表明,CeO2@MWCNTs纳米填料有利于减少涂层中的微孔。当CeO2@MWCNTs的含量增加到1.0%时,涂层表面形成许多小气泡,如图4k所示。涂层断裂面处出现裂纹和不均匀性,如图4l所示,1.0% CeO2@MWCNTs/EP涂层的断裂面较其它涂层粗糙。图5为不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层断面的EDS结果。结果表明,Ce含量随CeO2@MWCNTs含量的增加而增加;此外,1.0% CeO2@MWCNTs/EP涂层中Ce的分布不均匀,第2部分中的Ce含量是第1部分的近2倍。当CeO2@MWCNTs的含量达到1.0%时,CeO2@MWCNTs纳米填料容易在涂层中形成聚合。

图4

图4

不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的微观形貌

Fig.4

Cross section (a, d, g, j), surface (b, e, h, k) and fracture surface (c, f, i, l) morphologies of EP (a-c) coating and CeO2@MWCNTs/EP composite coatings with CeO2@MWCNTs content of 0.1% (d-f), 0.5% (g-i) and 1.0% (j-l)

图5

图5

不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层断面Ce的 EDS

Fig.5

EDS mapping of Ce in the fracture surface of CeO2@MWCNTs/EP composite coatings with CeO2@MWCNTs content of 0.1% (a), 0.5% (b) and 1% (c)

2.3 FT-IR分析

图5a为MWCNTs和CeO2@MWCNTs的FT-IR光谱。根据Sadtler编著的《红外光谱手册》[29],3430 cm-1处的吸收峰为游离水分子在碳纳米管表面缔合,因此出现了O-H键的伸缩振动峰。1640 cm-1处的特征峰为C=C的伸缩振动吸收峰。Ce-O键的振动吸收峰分别位于1377、822 、734 和607 cm-1,表明CeO2与MWCNTs之间只存在物理吸附,不存在化学键。图5b为不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP涂层的FT-IR光谱。O-H键的特征吸收峰在3430 cm-1,C-H键的伸缩振动吸收峰在2966 cm-1,C=C键的特征吸收峰在1640 cm-1,O-H键的变形振动吸收峰在1259 cm-1,1022 cm-1处为EP中C-O伸缩振动吸收峰,812 cm-1为环氧基团的特征吸收峰。这6个峰都属于EP涂层。由图5b可以看出,加入CeO2@MWCNTs后EP涂层的FT-IR光谱发生了变化,CeO2@MWCNTs (0.1%~1.0%)的含量对FT-IR光谱形状没有显著影响。加入CeO2@MWCNTs后,EP涂层中一些键的吸收峰减少,如2966 cm-1 (C-H键)、1259 cm-1 (O-H键)、1022 cm-1 (C-O键)和812 cm-1(环氧基)的吸收峰。而加入CeO2@MWCNTs后,复合涂层出现761 cm-1处的峰,该峰一定属于Ce-O键。0.5% MWCNTs/EP涂层的FT-IR光谱与EP涂层的基本相同。由此可以确定,MWCNTs对环氧树脂的结构没有影响,而纳米CeO2包覆在MWCNTs上可以改变环氧树脂的结构。此外,随着CeO2@MWCNTs含量的增加,CeO2对环氧树脂结构的影响可能是复合涂层微孔减少的另一个原因。

图6

图6

MWCNTs, CeO2@MWCNTs以及不同CeO2@- MWCNTs含量的CeO2@MWCNTs/EP复合涂层的FT-IR光谱

Fig.6

FT-IR spectra of MWCNTs and CeO2@MWCNTs (a), and CeO2@MWCNTs/EP composite coatings with different contents of CeO2@MWCNTs (b)

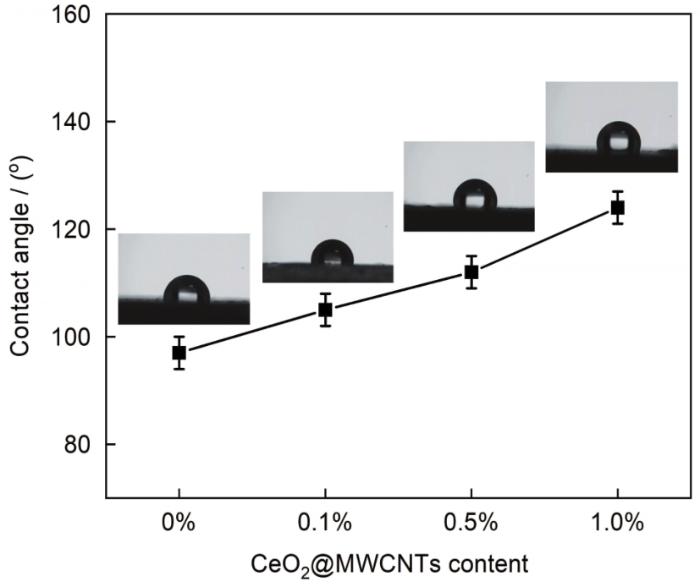

2.4 接触角测试结果分析

图7为不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的接触角测试结果。CeO2@MWCNTs/EP复合涂层的接触角均大于90°,即CeO2@MWCNTs/EP复合涂层均为疏水涂层。随着CeO2@MWCNTs含量的增加, CeO2@MWCNTs/EP复合涂层的接触角明显增大。根据图5b的数据,证明了CeO2可以改变环氧树脂的结构,如还原O-H键。O-H键很容易通过氢键与H2O结合,所以复合涂层的疏水性会随着CeO2@MWCNTs含量的增加而增加。一般来说,较大的接触角有利于提高耐蚀性。因此,CeO2@MWCNTs的含量可能会影响CeO2@MWCNTs/EP复合涂层的耐蚀性能。

图7

图7

不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的接触角测试结果

Fig.7

Contact angle test results of CeO2@MWCNTs/EP composite coatings with different contents of CeO2@MWCNTs

2.5 电化学测试结果分析

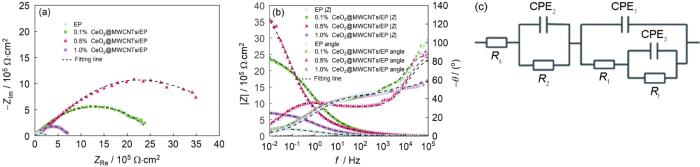

图8为X80钢表面添加CeO2@MWCNTs含量不同的CeO2@MWCNTs/EP复合涂层在3.5%NaCl溶液中的电化学阻抗谱和等效电路。一般来说,Nyquist图弧半径越大,对应的涂层耐蚀性越好。可以看出,在EP涂层中加入CeO2@MWCNTs可以显著提高耐蚀性。其中,0.5% CeO2@MWCNTs/EP复合涂层的阻抗最大,1% CeO2@MWCNTs/EP复合涂层的阻抗明显小于0.1% CeO2@MWCNTs/EP复合涂层。所以CeO2@MWCNTs/EP复合涂层的耐蚀性随CeO2@MWCNTs含量的增加先升高后降低,0.5% CeO2@MWCNTs/EP复合涂层在3.5% NaCl溶液中的耐蚀性最强。

图8

图8

不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的电化学阻抗谱及其等效电路

Fig.8

Nyquist (a) and Bode (b) plots of CeO2@MWCNTs/EP composite coatings with different contents of CeO2@MWCNTs and equivalent circuit (c)

为进一步研究不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的EIS结果,采用Zsimpwin软件拟合图8数据。X80表面涂层为单层膜,选用R(Q(R(QR)))型。另外,在图7中,涂层呈疏水性,则可以减少腐蚀介质与基体的接触面积,粗糙的表面将空气困在涂层与电解质的界面缝隙中,被捕获的空气就像一个纯平行板电容器的电介质。空气电介质可以减弱基底与电解质之间的电子传递能力,从而提高涂层的耐腐蚀性能,因此在等效电路模型中应加入(QR)部分[30]。研究EIS数据的等效电路模型为R(QR)(Q(R(QR))),如图8c所示。Rs为溶液电阻,R2和CPE2分别代表空气层电阻和电容,R1为涂层电阻,Rt为电荷转移电阻,CPE1、CPE2和CPE3是为了提高拟合精度,将纯电容替换后的恒相元件,其定义为:

其中,Q为常量,j为虚数单位,ω为角频率,n为膜层均匀性及完整性的系数(0≤n≤1)[31]。

表1给出了不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的EIS拟合结果。由表1可知,在EP涂层中加入CeO2@MWCNTs可以提高Rt和R1,且随CeO2@MWCNTs含量的增加先增大后减小。0.5% CeO2@MWCNTs/EP复合涂层的Rt和R1最大,EP涂层的Rt和R1最小。与不添加CeO2@MWCNTs的EP涂层相比,0.5% CeO2@MWCNTs/EP复合涂层的R1提高了4倍以上。致密性是影响涂层耐蚀性的关键因素。涂层的电阻随着CeO2@MWCNTs的加入而增加,这是由于涂层的致密性随CeO2@MWCNTs的增加而增加。而当CeO2@MWCNTs的含量达到1.0%时,涂层的电阻降低,这是因为当CeO2@MWCNTs的含量达到1.0%时,涂层中CeO2@MWCNTs形成团聚体。涂层疏水性引起的电阻R2随CeO2@MWCNTs的增大而增大。结合图7所示,可以证明增大疏水性可以提高耐蚀性。

表1 不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的EIS拟合结果

Table 1

| Sample | Rs Ω·cm2 | CPE2 | R2 Ω·cm2 | CPE1 | R1 Ω·cm2 | CPE3 | Rt Ω·cm2 | Error | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Y0S·s n ·cm-2 | n | Y0S·s n ·cm-2 | n | Y0S·s n ·cm-2 | n | ||||||

| EP | 8.93 | 9.45×10-9 | 0.88 | 0.45×103 | 1.39×10-8 | 0.92 | 2.43×104 | 1.72×10-6 | 0.67 | 2.54×105 | 5.69% |

| 0.1% CeO2@MWCNTs/EP | 8.12 | 1.43×10-9 | 0.93 | 0.74×103 | 2.42×10-9 | 0.91 | 0.92×105 | 2.39×10-7 | 0.63 | 2.66×106 | 6.47% |

| 0.5% CeO2@MWCNTs/EP | 8.37 | 1.58×10-6 | 0.81 | 1.16×103 | 3.49×10-10 | 0.97 | 2.94×105 | 6.42×10-7 | 0.45 | 3.54×106 | 4.08% |

| 1.0% CeO2@MWCNTs/EP | 8.76 | 1.72×10-6 | 0.84 | 1.59×103 | 2.41×10-9 | 0.93 | 4.78×104 | 8.38×10-7 | 0.57 | 5.62×105 | 7.92% |

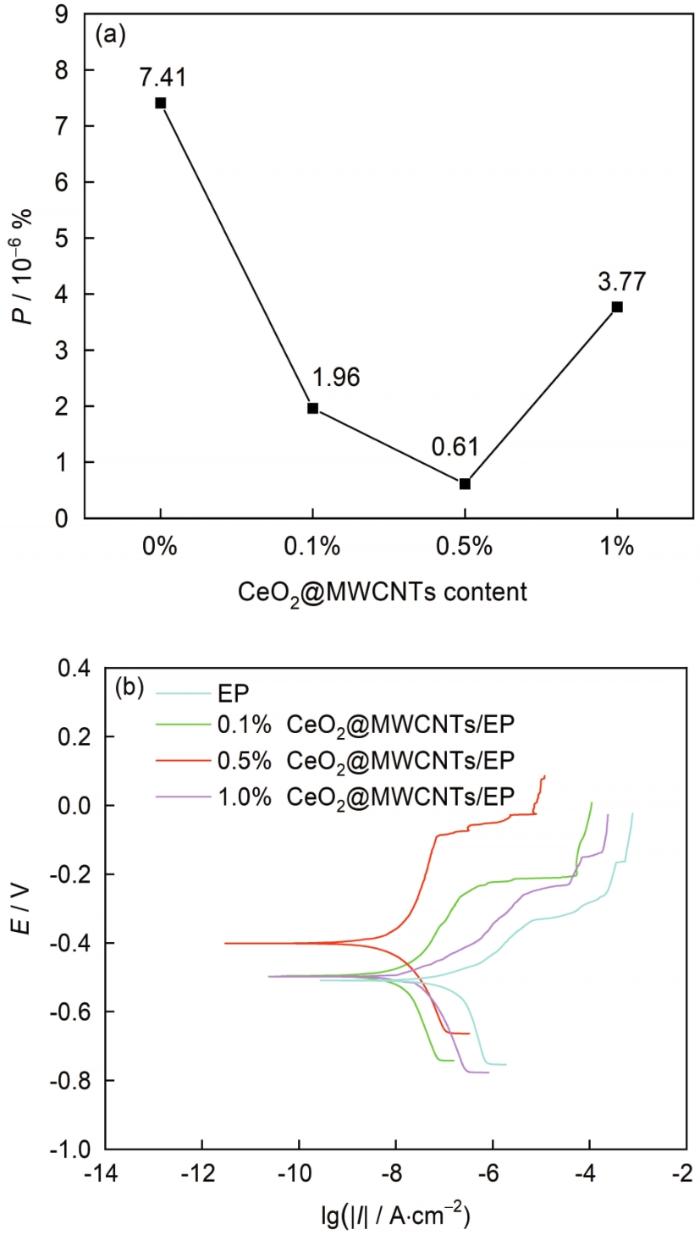

涂层孔隙率大小体现了涂层耐腐蚀性能的程度。孔隙率 (P) 可由孔隙率“无限大的”涂层的理论电阻 (Rpt) 与实测涂层电阻 (Rc) 的比值来确定[32]:

图9a为不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的孔隙率变化。孔隙率越大,意味着涂层中的微孔数量越多,腐蚀介质的传输通道越多,涂层的耐腐蚀性越差。由图9a可知,EP涂层的孔隙率最大,随CeO2@MWCNTs含量的增加,CeO2@MWCNTs/EP复合涂层的孔隙率先减小后增大。孔隙率越低,说明涂层致密性越好,就越能阻碍腐蚀介质的侵入,0.5% CeO2@MWCNTs/EP复合涂层的孔隙率最小,证明其耐腐蚀性能最佳。图9b为添加不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层在3.5% NaCl溶液中的动电位极化曲线。可以发现,阴极极化曲线的趋势和斜率大致相同,添加CeO2@MWCNTs会显著影响阳极进程。加入CeO2@MWCNTs后,0.5% CeO2@MWCNTs/EP复合涂层的阳极分支在-0.4~0.0 V较宽范围内,阳极电流密度随电位变化增幅极小,表现出类似钝化的状态;随着阳极电位的继续升高,外界电压击穿了涂层的双电层电容,阳极电流密度急剧增大,但电位变化不大,出现了类似点蚀的状态;然后阳极电流密度随电位升高继续増大,与EP涂层的极化曲线形状相似。图9b极化曲线的电化学参数如表2所示。0.5% CeO2@MWCNTs/EP复合涂层具有最高的腐蚀电位,即具有最佳的电化学热力学稳定性。此外,EP涂层具有最大的腐蚀电流密度,在EP涂层中加入CeO2@MWCNTs后,腐蚀电流密度明显降低,腐蚀电流密度越小,腐蚀速率也小。随着CeO2@MWCNTs含量的增加,CeO2@MWCNTs/EP复合涂层的腐蚀电流密度先减小后增大,0.5%的CeO2@MWCNTs/EP复合涂层的腐蚀电流密度最低。0.5% CeO2@MWCNTs/EP复合涂层的腐蚀电流密度比EP涂层降低了一个数量级,这与之前的研究一致。

图9

图9

不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的孔隙率变化与动电位极化曲线

Fig.9

Porosity variation curve (a) and dynamic poten-tial polarization curves (b) for CeO2@MWCNTs/EP composite coatings with different contents of CeO2@MWCNTs

表2 不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的拟合电化学参数

Table 2

| Sample | Ecorr / V | Icorr / µA·cm-2 |

|---|---|---|

| EP | -0.507 | 0.187 |

| 0.1% CeO2@MWCNTs/EP | -0.493 | 0.018 |

| 0.5% CeO2@MWCNTs/EP | -0.403 | 0.013 |

| 1.0% CeO2@MWCNTs/EP | -0.499 | 0.041 |

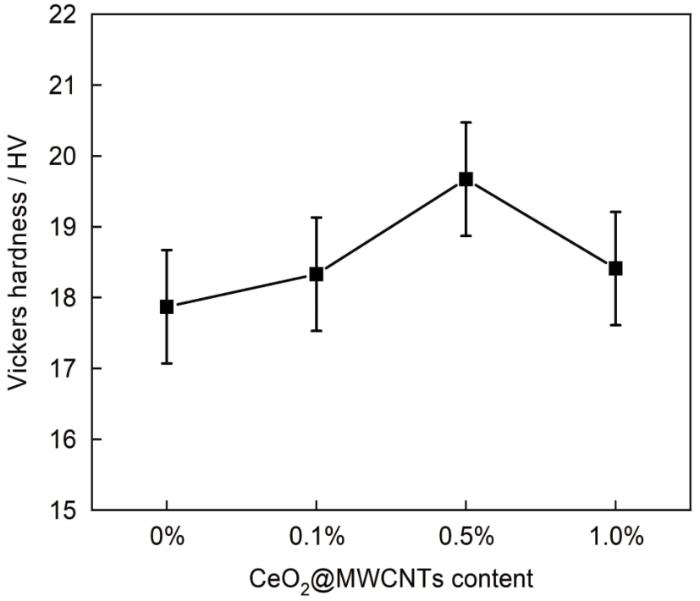

2.6 涂层硬度分析

图10为不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的维氏硬度。EP涂层的硬度为17.9 HV,随CeO2@MWCNTs含量从0%增加到0.5%,涂层的硬度逐渐增加,增加了10.1%。CeO2@MWCNTs作为添加剂,由于碳纳米管引起的纤维增强机制,可以提高涂层的硬度。此外,CeO2@MWCNTs有利于减少涂层中的微孔,如图4所示,这也有利于提高涂层的硬度。而当CeO2@MWCNTs的含量达到1.0%时,复合涂层的硬度下降到18.4 HV,下降了6.6%。这可能是由于CeO2@MWCNTs在涂层中的聚集,1.0% CeO2@MWCNTs复合涂层的硬度会受到涂层中CeO2@MWCNTs含量较低的柔软部分的影响 (图4l中的第1部分)。同时,不均匀的涂层容易出现应力集中,在涂层加载时容易产生缺陷。这两者都能降低涂层的硬度。

图10

图10

不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的维氏硬度

Fig.10

Vickers hardness values of CeO2@MWCNTs/EP composite coatings with different contents of CeO2@MWCNTs

2.7 摩擦磨损分析

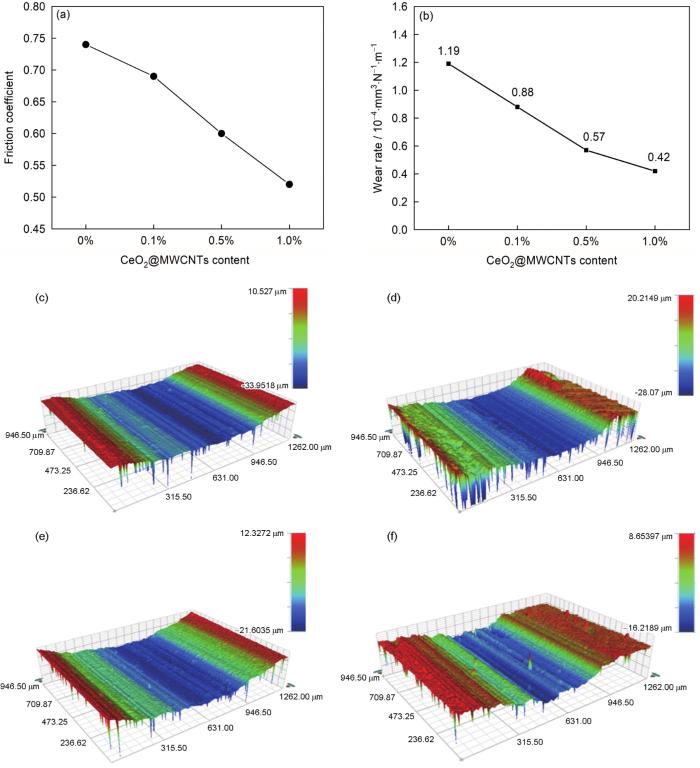

图11为不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的摩擦磨损结果。在图11a中,CeO2@MWCNTs/EP复合涂层的摩擦系数随CeO2@MWCNTs含量的增加而降低。EP涂层的摩擦系数为0.74,当CeO2@MWCNTs的含量增加到1.0%时,摩擦系数降低到0.52,降低了近30%。一般来说,减小摩擦系数可以提高材料的耐磨性。磨损率计算结果如图11b所示,随CeO2@MWCNTs含量的增加,复合涂层的磨损率逐渐降低。1.0% CeO2@MWCNTs/EP复合涂层的磨损率比EP涂层降低了64.7%。因此,CeO2@MWCNTs由于碳纳米管的存在应该具有润滑功能[34]。图11c~f为不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层摩擦实验后划痕的三维形貌。可以看出,划痕的宽度和深度随着CeO2@MWCNTs含量的增加而减小。EP涂层划痕的宽度约为950 μm,深度约为30 μm。1.0% CeO2@MWCNTs/EP涂层的划痕宽度约为400 μm,深度约为16 μm。当CeO2@MWCNTs的含量从0%增加到1.0%时,划痕的宽度和深度分别减少了57.8%和46.7%。结果表明,涂层中加入CeO2@MWCNTs有利于提高涂层的耐磨性。

图11

图11

不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层的摩擦磨损结果

Fig.11

Friction coefficients (a) and wear rates (b) of CeO2@MWCNTs/EP composite coatings with different contents of CeO2@MWCNTs, and 3D profiles of 0% (c), 0.1% (d), 0.5% (e) and 1.0% (f) CeO2@MWCNTs/EP composite coatings

在摩擦磨损过程中,所释放的CeO2@MWCNTs可以作为固体润滑剂,避免Al2O3球与涂层之间的直接接触。此外,CeO2@MWCNTs可以减少EP涂层中的微孔,如图4所示,也有利于降低摩擦系数。基于以上,可以证明在涂层中加入CeO2@MWCNTs有利于降低复合涂层的摩擦系数,提高复合涂层的耐磨性。

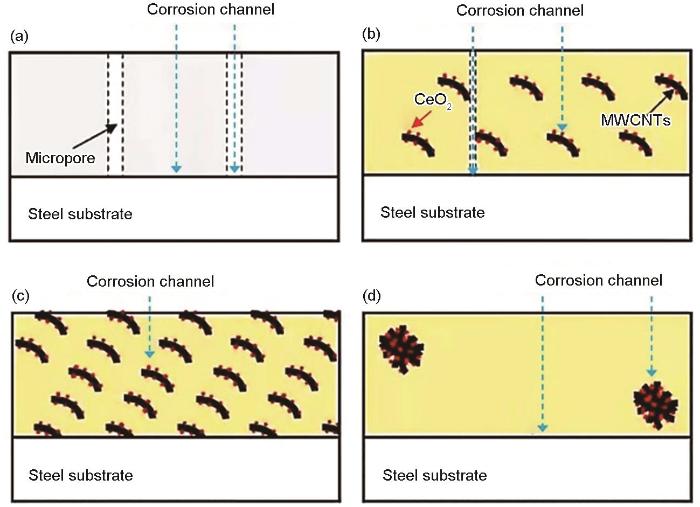

2.8 机理的讨论

基于以上研究,CeO2@MWCNTs对CeO2@MWCNTs/EP复合涂层耐蚀性能的影响机理如图12所示。将CeO2@MWCNTs加入到EP中后,纳米CeO2可以改变环氧树脂的结构 (图12b~d中用黄色标记),复合涂层的疏水性会增加,这有利于提高涂层的耐腐蚀性。此外,在涂层中加入CeO2@MWCNTs也可以减少涂层中的微孔。微孔可以为腐蚀介质渗透到涂层提供通道。在腐蚀过程中,传质过程可以通过图12中蓝色虚线箭头所示的腐蚀通道进行。因此,通过CeO2@MWCNTs引起的微孔和物理屏障的减少,可以减少传质过程。然而,当CeO2@MWCNTs含量过高时,CeO2@MWCNTs会在涂层中团聚在一起,如图12d所示。涂层中CeO2@MWCNTs含量较低的部分物理阻隔减少,这也是1.0% CeO2@MWCNTs/EP复合涂层腐蚀电流密度增大的原因。

图12

图12

不同CeO2@MWCNTs含量的CeO2@MWCNTs/EP复合涂层腐蚀机理示意图

Fig.12

Schematic diagrams of corrosion resistance of CeO2@MWCNTs/EP composite coatings containing 0% (a), 0.1% (b), 0.5% (c) and 1.0% (d) CeO2@MWCNTs

3 结 论

(1) 纳米CeO2可以改变EP的结构,在CeO2@MWCNTs/EP复合涂层中,随着CeO2@MWCNTs含量的增加,涂层的疏水性增加。

(2) 添加CeO2@MWCNTs有利于减少涂层中的微孔,而当CeO2@MWCNTs的含量达到1.0%时,它容易在涂层中团聚。随着CeO2@MWCNTs含量的增加,CeO2@MWCNTs/EP复合涂层的耐蚀性先增大后减小,这是由于涂层中存在微孔和CeO2@MWCNTs团聚所致。

(3) CeO2@MWCNTs在摩擦磨损过程中可作为固体润滑剂,有利于降低CeO2@MWCNTs/EP复合涂层的摩擦系数和磨损率。

参考文献

Challenges and developments in pipeline weldability and mechanical properties

[J].

Effect of H2S/CO2 partial pressure ratio on the tensile properties of X80 pipeline steel

[J].

Corrosion evaluation of SAW welded API 5L X-80 joints in H2S-containing solution

[J].

Research progress of galvanic corrosion in marine environment

[J].

海洋环境中金属电偶腐蚀研究进展

[J].

Anticorrosive coatings: a review

[J].

Fabricating an epoxy composite coating with enhanced corrosion resistance through impregnation of functionalized graphene oxide-co-montmorillonite Nanoplatelet

[J].

Highly dispersed graphene oxide-zinc oxide nanohybrids in epoxy coating with improved water barrier properties and corrosion resistance

[J].

Enhancement of barrier and corrosion protection performance of an epoxy coating through wet transfer of amino functionalized graphene oxide

[J].

Investigation of corrosion protection properties of an epoxy nanocomposite loaded with polysiloxane surface modified nanosilica particles on the steel substrate

[J].

Silane modification of titanium dioxide-decorated graphene oxide nanocomposite for enhancing anticorrosion performance of epoxy coatings on AA-2024

[J].

Effect of MWCNTs content on corrosion resistance of chromium-free zinc-aluminum coatings

[J].

多壁碳纳米管含量对无铬锌铝涂层耐蚀性能的影响

[J].针对无铬锌铝涂层耐蚀性不足的问题,通过超声波分散的方法制备了不同多壁碳纳米管 (MWCNTs) 含量的无铬锌铝涂层,研究了MWCNTs含量对无铬锌铝涂层宏观及微观形貌、成分、结合力及耐蚀性能的影响。结果表明:添加MWCNTs质量分数为0%~0.7%时,所有涂层外观均完整平滑,连续致密。MWCNTs含量为0.3%时,在涂层中分散良好,涂层结合力最佳,耐NaCl溶液腐蚀性能最好,且可以为基体提供良好的阴极保护作用,其自腐蚀电流密度仅为2.019×10<sup>-5</sup> A/cm<sup>2</sup>,阻抗模量较未加MWCNTs的涂层大一个数量级。此外,对MWCNTs影响涂层耐蚀性的机理也进行了分析。

A review on application of carbon nanostructures as nanofiller in corrosion-resistant organic coatings

[J].Since corrosion has tremendous economic effects, academics and industries have sought to develop more effective coatings. These efforts have led to profound importance of nanocomposite coatings based on polymers and carbon nanostructures. It is shown that good reinforcement, advanced mechanical properties, and high corrosion resistance are only found at relatively low levels of nanocarbon (i.e., fullerene, carbon black, carbon nanotubes, graphene, graphene oxide, and carbon dots) loadings in coating compositions. Herein, a survey of breakthrough scientific studies on application of carbon nanostructures in corrosion-resistant organic coatings is carried out to pave the way for future developments in novel nanocoatings.

Effect of nano-TiO2 particles size on the corrosion resistance of alkyd coating

[J].

Effect of nano-ZnO particles on the corrosion behavior of alkyd-based waterborne coatings

[J].

Sol-gel route to ceria coatings on AA2024-T3 aluminum alloy

[J].

Effect of nano-CeO2 on anticorrosion performance for polyurethane coating

[J].

添加纳米CeO2对聚氨酯涂层防腐性能的影响

[J].采用盐雾和盐水浸泡加速实验,结合ATR-FTIR,SEM,AFM表面分析技术及EIS电化学分析技术,考察纳米CeO<sub>2</sub>作为涂层颜料对聚氨酯涂层防腐性能的影响。结果表明,添加纳米CeO<sub>2</sub>能改善涂层的防腐性能,延缓聚氨酯涂层的阻抗衰减进程,但同时会削弱涂层在金属基体上的附着力。当添加量较低时 (≤0.5%,质量分数),由于H<sub>2</sub>O和侵蚀性离子渗入聚氨酯层,纳米CeO<sub>2</sub>水解流失,导致涂层阻抗谱随时间降低较快;当添加量达到1.0%时,涂层阻抗在较长时间内保持较高值,这可能是由于纳米CeO<sub>2</sub>在涂层微孔中发生水解膨胀,压缩了孔隙通道,同时Ce (III,IV) 迁移到铝合金/涂层界面,抑制了腐蚀活性位点,因而减缓了阻抗的衰减进程。然而,在盐雾实验后期,CeO<sub>2</sub>进一步水解会导致Ce<sup>4+</sup>的溶解流失,造成微孔隙的再次疏通和涂层阻抗的快速下降。过量添加 (>1.0%) 还会削弱涂层在铝合金基体上的附着力。长期浸泡实验结果表明:添加1.0%CeO<sub>2</sub>可基本实现Ce<sup>4+</sup>溶解和流失的平衡,增强聚氨酯涂层的防腐性能。

Electrochemical investigation of the inhibition effect of CeO2 nanoparticles on the corrosion of mild steel

[J].

Investigation on the effect of nano-ceria on the epoxy coatings for corrosion protection of mild steel in natural seawater

[J].This paper aims to investigate the effect of introducing nano-ceria (CeO2) particles to the epoxy coatings on mild steel in natural seawater.

Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: a review

[J].

Epoxy functionalization of multiwalled carbon nanotubes for their waterborne polyurethane composite with crosslinked structure

[J].

Modification of carbon nanotubes by a novel biomimetic approach towards the enhancement of the mechanical properties of polyurethane

[J].

Non-covalent functionalized multi-wall carbon nanotubes filled epoxy composites: Effect on corrosion protection and tribological performance

[J].

Effects of carbon nanotube content on adhesion strength and wear and corrosion resistance of epoxy composite coatings on AA2024-T3

[J].

Erosion studies of cermet-coated ASTM A36 steel

[J].Purpose This paper aims to perform the solid particle erosion studies in simulated coal-fired boiler conditions with a view to compare the erosion behavior of two different types of detonation gun (D-Gun) sprayed cermet coating powders, that is, WC-12%Co and Cr3C2-25%NiCr on ASTM A36 steel and bare (uncoated) ASTM A36 steel. Design/methodology/approach Erosion studies were performed using an air jet erosion test rig at impingement angles of 45 degrees, 60 degrees and 90 degrees. During the erosion studies weight loss, erosion rates in terms of volume loss (mm(3)/g) and measurement of erosion profiles were determined using optical profilometer. Findings Both cermet coatings had successfully protected the ASTM A36 steel from erosion at impingement angles of 45 degrees, 60 degrees and 90 degrees. In the case of bare ASTM A36 steel, the erosion rates were maximal at an impingement angle of 45 degrees and minimal at an impingement angle of 90 degrees, thus depicting the peculiar erosion behavior of ductile materials. WC-12%Co coated specimens exhibited erosion behavior that is closer to the behavior of ductile materials. Cr3C2-25%NiCr coated specimens exhibited the maximum erosion rate at an impingement angle of 90 degrees and minimum at an impingement angle of 45 degrees, hence depicting the typical behavior of brittle materials. Practical implications It is expected that these results will contribute to the improvement of erosion resistance of induced draft fans, by the application of D-Gun sprayed WC-12%Co and Cr3C2-25%NiCr cermet coatings. Originality/value This paper evaluates the solid particle erosion behavior of bare and cermet-coated ASTM A36 steel which will be helpful in choosing the suitable cermet coating for induced draft fan applications.

Graphene oxide–cerium oxide hybrids for enhancement of mechanical properties and corrosion resistance of epoxy coatings

[J].

X-ray induced reduction effects at CeO2 surfaces: an X-ray photoelectron spectroscopy study

[J].

The effect of ceria and zirconia nanoparticles on the corrosion behaviour of cataphoretic epoxy coatings on AA6060 alloy

[J].

Composition and corrosion resistance of cerium conversion films on the AZ31 magnesium alloy and its relation to the salt anion

[J].

Fabrication of superhydrophobic calcium phosphate coating on Mg-Zn-Ca alloy and its corrosion resistance

[J].

The analysis of electrode impedances complicated by the presence of a constant phase element

[J].

UV photo-degradation of coatings

[J].

紫外光对涂层的老化作用

[J].用人工加速的方法研究了紫外光对涂层的影响.用石英晶体微天平(QCM)测试发现老化后涂层对H2O和SO2的吸附率明显增大.电化学阻抗(EIS)测定发现孔隙率随光照射时间增加而增大,涂层电阻随光照时间增加而减小.傅利叶变换红外光谱(FTIR)分析表明,光照使涂层分子碳链断裂,醇酸涂层发生在芳香酯的C-O键,聚氨酯涂层发生在芳香酯的C-O键和氨酯键C-N,同时有一些亲水基团生成.用扫描电子显微镜(SEM)观察涂层表面产生了许多孔穴.涂层吸水率增加是由亲水基团增加和孔隙增加共同引起的,但孔隙增加的贡献更大.而涂层对SO2吸附率的增加是由双键α-H过氧化物的增加和孔隙的增加共同引起的,α-H过氧化物的增加的贡献更大.

Electrochemical impedance spectroscopy study of corrosion behavior of solvent-free epoxy coatings on steel substrate

[J].

应用EIS研究改性无溶剂环氧防腐涂层的防护性能和腐蚀特征

[J].

Fabrication of novel CeO2/GO/CNTs ternary nanocomposites with enhanced tribological performance

[J].Increasing demands of multi-functional lubricant materials with well distributed nanoparticles has been generated in the field of oil lubrication. In this study, one-dimensional (1-D) acidified multi-walled carbon nanotubes (CNTs) and two-dimensional (2-D) graphene oxide (GO) sheets were dispersed together under an ultra-sonication condition to form CNTs/GO hybrids and the corresponding CNTs/GO hybrids decorated with uniform zero-dimensional (0-D) cerium oxide (CeO2) nanoparticles were prepared via a facile hydrothermal method. The tribological performance of CeO2/CNTs/GO ternary nanocomposite was systematically investigated using a MS-T3000 ball-on-disk tester. The results demonstrated that CeO2/GO/CNTs nanocomposites can effectively reduce the friction of sliding pairs in paraffin oil. Moreover, the oil with 1 wt% of CeO2/GO/CNTs exhibited the best lubrication properties with the lowest friction coefficient and wear scar diameters (WSD) compared with adding only GO nanosheet, CeO2, and CeO2/CNTs hybrid nanocomposite as lubricant additives. It is concluded that due to the synergistic effect of 0D CeO2, 1D CNTs, and 2D GO during sliding process, a dimensionally mixed CeO2/GO/CNTs nanocomposite exhibits excellent lubricating properties, providing innovative and effective additives for application in the field of lubrication.