AISI 4130钢 (35CrMo) 是ASTM29标准中的一种低合金钢,其中含有质量分数为1%Cr和0.2%Mo作为增强元素,能够阻止奥氏体向珠光体转化,显著提高强度、硬度、耐磨性及淬透性[1]。AISI 4130钢广泛用于制造锻造油气阀体、连杆和石油深井钻杆接头等[2],由于温度、腐蚀介质以及较大冲击造成工件的磨损占失效的90%以上[3]。因此,提高AISI 4130钢工件表面的抗磨损性能势在必行。通过表面改性技术,如热喷涂、激光熔覆和激光喷丸[4]等来强化金属材料性能已经成为国内外学者广泛关注的研究方向。其中,激光淬火 (LQ) 已经被广泛用于提高曲轴、齿轮和气缸等工件的耐磨性,该方法是利用高能激光束迅速加热材料表面,当材料表面温度到达相变温度后快速冷却,形成晶粒细化的马氏体组织淬硬层,使得工件表面得到强化的过程[5]。同时,该技术具备高精度、热影响区小、碳化物分散均匀以及晶粒更加细化的优势[6]。克服了传统淬火持续时间长,需要整个构件同时淬火,最终获得的表面硬化层无规律及工件变形大等缺点[7]。此外,激光表面淬火不改变工件尺寸和表面粗糙度,可提高其工件耐磨性和抗疲劳性[8],较传统淬火具有更高的表面硬度[9]。Chen等[10]对高铬铸铁进行淬火回火 (QT) 和LQ处理,结果表明LQ对试样显微硬度的强化效果最优,与QT相比,LQ加热冷却速率快,易形成温度梯度,产生更细的马氏体组织和更多的碳化物,大幅度增强高铬铸铁的耐磨性;LQ试样的摩擦系数下降9.70%,磨损率下降11.32%。激光工艺参数,如激光功率、光斑尺寸及扫描速率是决定材料淬火质量的关键,有研究结果显示激光功率对材料的奥氏体化程度起决定性作用,从而进一步影响材料表面硬度[11, 12]。杨骏龙等[3]对35CrMo钢进行激光淬火处理,研究了激光功率对35CrMo钢奥氏体化程度的影响机制。研究表明激光功率为3.2 kW的试样表面硬度提高了20%,耐磨性比功率为1.6和2.4 kW处理的材料明显提高。Li等[13]对1.0C-1.5Cr钢进行了传统淬火和激光表面淬火研究,与传统淬火相比,LQ试样的表面硬度提高约20%,有益于增强其耐磨性能。单淬火与双淬火后的冲击吸收能量相似,约为淬火前的25%。Pantelis等[14]采用4种不同搭接率对CK60结构钢进行了激光表面处理,结果表明,使用0%和38%搭接率处理的试样具有更优越的耐磨性。在所有研究的试样中,搭接率为0%处理的试样具最优的耐蚀耐磨性能。此外,LQ工艺也存在其他问题,如激光功率密度及激光不均匀性会影响淬火工艺的稳定性,工件初始状态对淬火质量影响较大,淬火材料表面存在应力不均匀的现象和激光表面淬火难以保证大面积硬化层。

因此,本文研究了激光功率对AISI 4130钢表面淬火的影响,并对淬火层深度、组织演变特征、显微硬度和耐蚀耐磨性等进行了研究,揭示了激光功率对AISI 4130钢的微观组织结构及性能的影响机制,为探究高质量LQ技术提供理论依据。

1 实验方法

本实验采用的基体材料为AISI 4130合金结构钢,其化学成分 (质量分数,%) 为:C 0.28~0.33,Si 0.15~0.35,Mn 0.40~0.60,Cr 0.80~1.10,Mo 0.15-0.25,Ni≤0.03,Cu≤0.03,Fe余量。

图1

激光表面淬火试样被切割成10 mm×10 mm×8 mm (L×W×H) 的立方体。首先采用600~2000#的SiO2砂纸对试样截面进行打磨,随后用金刚石膏抛光为镜面,然后采用无水乙醇冲洗并吹干,最后采用体积分数为4%的硝酸溶液蚀刻约10 s。利用配备能量色散光谱 (EDS) 的扫描电镜 (SEM,EV0 MA15) 观察试样的微观组织结构特征,并利用EDS在加速电压20 kV、探针电流500 pA和采集时间240 s下研究试样截面元素分布特征。采用X射线衍射仪 (XRD,X Pert PRO MPD) 对试样进行物相组成研究。

采用CS310H电化学工作站,将试样、铂片 (Pt)和饱和甘汞电极分别作为工作电极、对电极和参比电极,对淬火试样进行电化学行为测试。电化学测试前,每个试样底部和周边均用环氧树脂密封,腐蚀液为3.5% (质量分数) NaCl溶液,每种条件下试样重复测量3次。截面硬度采用维氏显微硬度仪 (HV-1000STA)测量,测试方法为距淬火表面约50 μm开始测试,0.05~1.05 mm之间每隔0.04 mm测量一个点,1.05 mm后每隔0.25 mm测量一个点。载荷为200 gf,停留时间为15 s。采用UMT-2摩擦磨损试验机在试样表面进行往复磨损,行程为5 mm,摩擦速率为5 mm/s,载荷为80 N。此外,使用三维光学显微镜 (布鲁克轮廓GT-K) 获得磨损划痕的三维形态。

2 结果与分析

2.1 激光淬火AISI 4130钢的微观组织结构特征研究

图2

图2

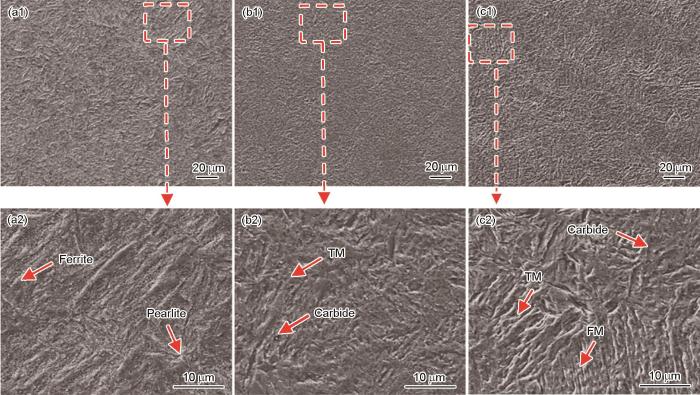

AISI 4130钢基材与淬火试样的表面微观结构

Fig.2

Surface microstructure of AISI 4130 steel substrate (a1, a2) and quenched samples with laser power of 2.0 kW (b1, b2) and 2.2 kW (c1, c2)

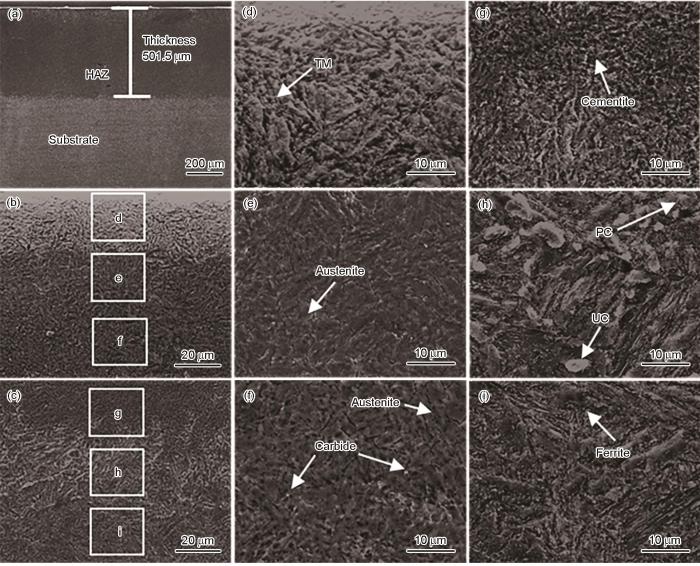

图3和4为AISI 4130钢在2.0和2.2 kW激光淬火后的截面微观组织。两种处理试样的热影响区厚度分别为501.5和553.6 µm,激光硬化层厚度随激光功率的增加而增加。将两种处理试样的淬硬区 (HAZ) 根据微观组织特征划分为6个不同的区域 (d~i)。近表面d区由于快速淬火过程造成的垂直温度梯度导致形成了TM。由表至内激光加热温度逐渐降低,次表层e区组织主要为马氏体及未溶解碳化物。f和g区为不完全淬火层,出现奥氏体及渗碳体,且越靠近基体铁素体含量越多。h区为高温回火区,组织主要为铁素体、珠光体及析出渗碳体 (PC),以及未溶渗碳体 (UC)[17, 18]。i区到达基体,组织为铁素体及少量珠光体。与基材 (图3i和4i) 相比,淬火试样 (图3d和 4d) 内部产生较多马氏体,保留少量残余奥氏体,晶粒细化明显,碳化物分散均匀。

图3

图3

AISI 4130钢2 kW激光淬火后截面的微观组织

Fig. 3

Cross-sectional microstructure of AISI 4130 steel after 2 kW laser quenching: (a) cross-sectional quenching layer thickness, (b) Near-surface quenching zone, (c) hardened zone and matrix transition zone, (d-i) corresponding zones in Fig.3b and c

图4

图4

AISI 4130钢2.2 kW激光淬火后截面的微观组织

Fig.4

Cross-sectional microstructure of AISI 4130 steel after 2.2 kW laser quenching: (a) cross-sectional quenching layer thickness, (b) Near-surface quenching zone, (c) hardened zone and matrix transition zone, (d-i) corresponding zones in Fig.4b and c

与2.0 kW淬火试样相比,2.2 kW淬火试样马氏体相变转化率较高,保留残余奥氏体较少,马氏体组织分布相对均匀,淬火效果相对较好。原因是在淬火过程中,激光功率越高,其对表面的升温速率越快,使得奥氏体形核并长大速率加快,冷却后形成的马氏体组织将更加稳定。由此表明,随着功率增加,淬火层厚度与马氏体含量逐渐增加,这与Liu等[19]研究结果一致。

图5为AISI 4130钢淬火试样的截面元素分布特征。由图可知,2.0 kW淬火试样O含量从表面到40 µm处显著增加,2.2 kW淬火试样O含量从表面到75 µm处含量显著增加,但波动较大。Fe由内部至表面逐渐降低,2.0 kW及2.2 kW淬火试样分别降低13.9%和13.5%。这可能是由于淬火过程马氏体转变引起热影响区O含量变化,导致Fe和O含量的相对变化。当高功率激光束照射试样表面时,由于试样的导热性,表层将会形成温度梯度。因此,在LQ过程中试样表面温度剧烈增加,导致Fe与O2发生反应;距离试样表面越近,O含量及温度越高,加速反应的进行,导致Fe由内至表面含量逐渐减少[20]。两种试样Fe变化的区域厚度,都处于前图中的f区及以上,由此可知随功率的增加,Fe含量的降低越不明显。图6为AISI 4130钢基材与LQ试样表面的XRD谱,可以看出,淬火并不会明显改变试样的物相。

图5

图5

AISI 4130钢淬火后截面元素分布特征

Fig.5

Cross-sectional element distribution of AISI 4130 steel after quenching: (a, b) 2.0 kW, (c, d) 2.2 kW

图6

图6

AISI 4130钢基材与LQ试样的XRD谱

Fig.6

XRD patterns of AISI 4130 steel substrate and laser quenching samples

2.2 激光淬火AISI 4130钢的耐蚀性研究

图7

图7

AISI 4130钢基材与2.0 kW、2.2 kW功率LQ试样的EIS图

Fig.7

EIS diagram of AISI 4130 steel substrate and two quenched samples in 3.5% NaCl solution: (a) Nyquist diagram and corresponding equivalent circuit, (b) Bode diagram

表2 AISI 4130钢在不同激光功率下阻抗拟合数据

Table 2

| Laser power / kW | Rs / Ω·cm2 | Y / Ω-1·cm-2·s-n | n | Rf / Ω·cm2 | L / H·cm2 | Rct / Ω·cm2 |

|---|---|---|---|---|---|---|

| As-received | 2.88 | 85.36×10-5 | 0.80 | 1124 | 4371 | 4738 |

| 2.0 | 2.34 | 128.00×10-5 | 0.79 | 3005 | 3343 | 1326 |

| 2.2 | 2.33 | 145.70×10-5 | 0.78 | 1029 | 3558 | 2598 |

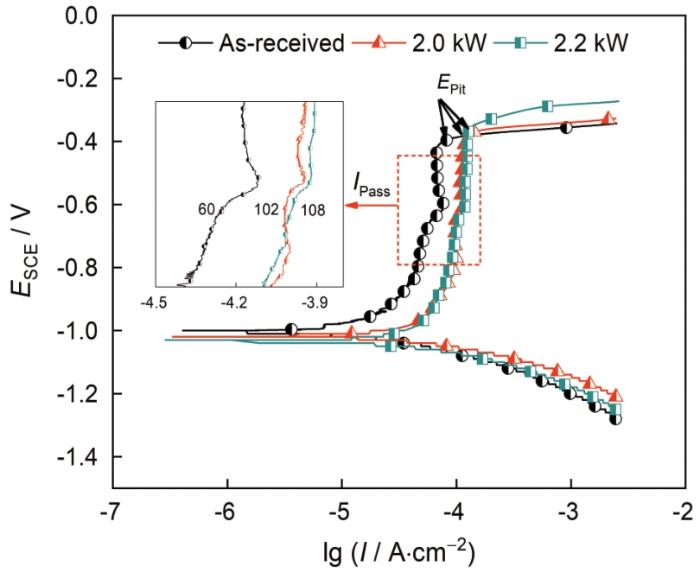

图8为基材与两种LQ试样的动电位极化曲线。可知,基材与LQ试样均在阳极支上出现了明显的类钝化现象,淬火试样的极化曲线均向右移动,2.0 kW与2.2 kW的维钝电流密度约为基材的1.7倍。表明淬火试样的耐蚀性降低,且2.0 kW试样比2.2 kW试样的耐蚀性更优。

图8

图8

AISI 4130钢基材与2.0和2.2 kW功率LQ试样的动电位极化曲线

Fig.8

Potential polarization curves of AISI 4130 steel substrate and two quenched samples with laser power of 2.0 and 2.2 kW in 3.5% NaCl solution

2.3 激光淬火AISI 4130钢的耐磨性研究

图9为AISI 4130钢与两种功率LQ试样截面的显微硬度分布特征。可知,淬火层硬度呈现由表面向内部逐渐降低的趋势;与2.0 kW淬火试样相比,2.2 kW淬火试样热影响区硬度较大;其平均硬度如图9b所示,与基体相比,其硬度分别提高85%、95%。当未达到表面熔化的临界热输入量时,激光能量越大,奥氏体化程度越慢。因此,在冷却时,会出现更多的马氏体,使得表面硬度提高。此外,图中靠近基体的A,C点,硬度有明显上升。由于A、C点冷却速率快,未到达晶粒长大的临界值,所以其晶粒比B、D点细小,与图2和3表现一致。且越靠近基体,A,C点马氏体含量比B,D点少,因此晶粒细化是导致A,C点硬度小幅度提高的原因[20]。

图9

图9

AISI 4130钢在2.0和2.2 kW功率LQ后的截面显微硬度分布特征

Fig.9

Microhardness of AISI 4130 steel after laser quenching at 2.0 and 2.2 kW power: (a) cross-sectional microhardness, (b) average hardness of the hardened zone specimen

图10为AISI 4130钢基材与两种功率LQ试样的摩擦系数曲线。可知,在磨损的起始阶段,试样的摩擦系数 (COF) 都在短时间内整体上升,此时处于磨合磨损阶段。当进入稳定磨损阶段大约500 s时,所有试样的COF都会略微下降,这表明磨损后表面粗糙度降低,试样表面的实际磨损面积和接触点的数量增加导致了COF的降低,随后抛光面被破坏,COF增大。稳态磨损阶段,AISI 4130钢基材与2.0 kW和2.2 kW LQ试样的平均COF如图10b,与基材试样相比,LQ试样的摩擦曲线更加平缓,COF降低,淬火试样耐磨性分别提高20%和47%,说明2.2 kW淬火试样耐磨性最好。这是因为淬火后细小的碳化物以及马氏体的形成,试样的表面硬度增加,耐磨性也得到提高[22]。这与Pantelis等[14]研究结果一致。

图10

图10

AISI 4130钢基材与2.0和2.2 kW功率LQ后试样的摩擦系数

Fig.10

Friction coefficient of AISI 4130 steel substrate and two quenched samples with laser power of 2.0 and 2.2 kW: (a) coefficient of friction varying with time, (b) average coefficient of friction

3 讨论

3.1 激光淬火对AISI 4130钢耐蚀性的影响机制

图11

图11

浸泡24 h后的表面微观形貌及截面元素分布

Fig.11

Surface morphologies (a1-c1) and cross-sectional element distribution (a2-c2) of AISI 4130 steel substrate (a1, a2) and two quenched samples with laser power of 2.0 kW (b1, b2) and 2.2 kW (c1, c2) after 24 h immersion in 3.5% NaCl solution

图12

图12

AISI 4130钢基材和淬火试样的腐蚀机理示意图

Fig.12

Schematic diagram of corrosion mechanism of AISI 4130 steel substrate (a) and quenched sample (b)

Fe(OH)2不稳定,可进一步与O2反应并发生相变,脱水或还原反应生成稳定的

Cl-存在于腐蚀溶液,可以破坏腐蚀产物膜的薄弱区,促进O2及溶液对金属表面的接触面积,在金属表面发生点蚀,如下所示。

图12b为激光淬火后AISI 4130钢的腐蚀机理。淬火试样中析出富含Cr的碳化物颗粒[24],由于颗粒附近Cr含量相对较低,在Cr耗尽区无法形成腐蚀产物膜,或者由于Cl-破坏腐蚀产物膜渗透到金属表面,腐蚀产物膜将不连续,无保护作用[25],Cr的耗尽区将快速被腐蚀,加剧腐蚀产物膜的破坏,导致淬火试样的耐腐蚀性降低[21, 22, 26]。此外,由于多相微观组织,包括铁素体、残余奥氏体和大量碳化物的存在导致不同相间界面上的电偶腐蚀,促进腐蚀加剧。因此,淬火试样的耐蚀性降低。与2.2 kW淬火试样相比,2.0 kW淬火试样的耐蚀性较好,这可能是由于其残余奥氏体的含量较高,对降低试样的腐蚀速率具有积极作用[27]。

3.2 激光淬火对AISI 4130 钢耐磨性的影响机制

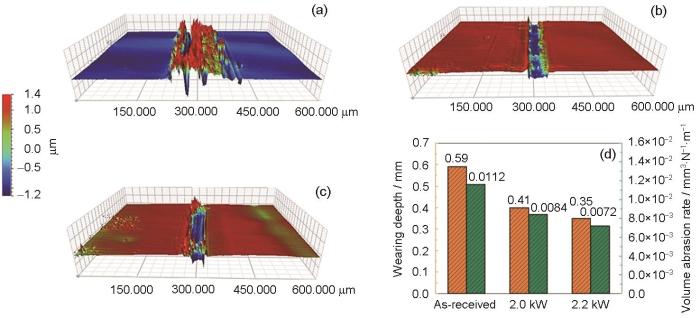

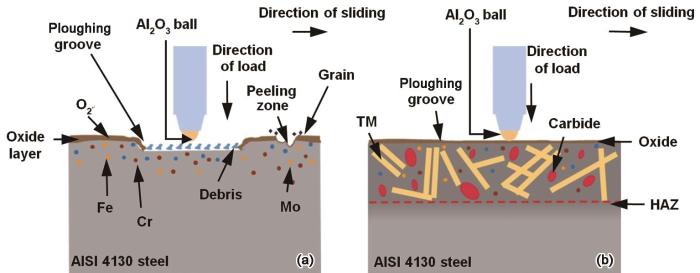

图13为AISI 4130钢基材与两种LQ试样的表面磨损形貌。可知,基材磨损表面分布着较多氧化物磨损碎屑和犁沟,一些碎片从基底上剥落,新的表面暴露在空气中,进一步被氧化。与基材相比,LQ试样表面氧化磨损碎屑较少,磨损表面较光滑,没有发生剥落现象,表明粘着磨损有所改善,耐磨性有所提高。与2.0 kW淬火试样相比,2.2 kW淬火试样磨损表面较光滑,硬颗粒难以保留在淬火表面上,这可能是由于磨损表面的碳化物是影响材料耐磨性的主要因素。

图13

图13

AISI 4130钢磨损划痕及元素分布

Fig.13

Wear morphology and mapping analysis of AISI 4130 steel: (a1, a2) substrate, (b1, b2) 2.0 kW LQ sample, (c1, c2) 2.2 kW LQ sample

图14

图14

AISI 4130钢磨损后3D形貌

Fig.14

3D morphologies (a-c), wear depth and volume wear rate (d) of AISI 4130 steel substrate (a) and two quenched samples with laser power of 2.0 kW (b) and 2.2 kW (c) after wear

式中,L为摩擦长度,m;R为硬质合金球半径,mm;

图15为AISI 4130钢基材和LQ试样的磨损机理。如图15a所示,在法向载荷下Al2O3摩擦副使试样表面形成不完全氧化层,当氧化层被破坏后,试样的金属表面在大气中重新氧化,氧化膜中存在Fe2+、Fe3+、Cr3+、Mo4+和Mo5+等阳离子,具有一定润滑作用[30]。当剪切应力和磨损热作用于试样表面时,碎片弯曲、氧化成为磨料颗粒。通过硬颗粒的运动,试样表面受到犁沟效应,形成犁沟,且导致氧化物不完整,从而加速氧化磨损。因此,基材试样的磨损机制主要为粘着磨损、氧化磨损和磨粒磨损,疲劳磨损。对于淬火试样,如图15b所示,磨损机理主要为轻微磨损及氧化磨损。首先,马氏体及Cr的碳化物具有极高硬度,阻止了表面被严重磨损[31]。其次,淬火试样中残余奥氏体具有较好的可塑性,可减少冲击[32]。最后,淬火试样表面碳化物含量越高,磨料上的凸面越难切割成坚韧相,因此降低了试样表面的磨损率[33],从而提高了材料的整体耐磨性。

图15

图15

AISI 4130钢基材和淬火试样的磨损机理示意图

Fig.15

Schematic diagram of wear mechanism of AISI 4130 steel substrate (a) and quenched sample (b)

4 结论

(1) 经2.0和2.2 kW LQ后,2.2 kW的淬火试样热影响区厚度较大,且马氏体相变转化率较高,淬火效果相对较好,淬火后显微硬度提高,耐蚀性下降,但耐磨性增强。

(2) AISI 4130钢基材与两种LQ试样的阻抗弧半径从小到大依次为2.2 kW淬火试样、2.0 kW淬火试样和基材。2.0与2.2 kW LQ试样的钝化电流密度约为基材的1.7倍,两种结果表明,LQ试样的耐蚀性降低,且2.0 kW试样比2.2 kW试样的耐蚀性更优。LQ试样中析出富含Cr的碳化物颗粒,及多相微观组织的存在将加剧腐蚀产物膜的破坏,导致LQ试样的耐腐蚀性降低。

(3) AISI 4130钢LQ后热影响区平均硬度明显提高,LQ试样耐磨性明显提高,且2.2 kW LQ试样耐磨性最好。由于淬火后马氏体及Cr的碳化物具有极高硬度,能够进一步提高抗剥落能力,且表面碳化物含量越高,试样表面的磨损率越低,材料整体耐磨性越好。

参考文献

Research and application progress of ultra-high strength structural steel

[J].

超高强度结构钢的研究及发展

[J].

Invalid analysis of 35CrMo steel drill pipe thread fracture used in engineering

[J].

工程用35CrMo钢钻杆螺纹断裂失效分析

[J].

Effect of high-power laser quenching on microstructure and wear resistance of 35CrMo steel surface layer

[J].Surface quenching treatment of 35CrMo steel was carried out by high power laser. The microstructure, hardness and wear resistance of surface layer under different laser power(1.6,2.4,3.2,4.0 kW) were studied. The results show that when the laser power was 1.6 and 2.4 kW, the undissolved ferrite existed on the surface layer of 35CrMo steel, and the surface layer hardness was lower than that of the substrate; the wear mass rate of the steel was almost the same as that of the substrate after grinding with GCr15 steel, indicating the steel had bad wear resistance. When the laser power was 3.2, 4.0 kW, the surface layer microstructure was all tempered martensite, and the average surface layer hardness reached 640 HV, which was about 20% higher than that after conventional water quenching. The wear mass rate under laser power of 3.2 kW was the lowest, no obvious wear trace could be found on the surface, and the wear resistance was significantly improved compared with the substrate. When the laser power was up to 4.0 kW, the higher self-tempering degree of martensite resulted in a slight decrease in hardness and wear resistance compared with the laser power of 3.2 kW.

高功率激光淬火对35CrMo钢表层组织与耐磨性能的影响

[J].采用高功率激光器对调质态35CrMo钢进行表面淬火处理,研究了不同激光功率(1.6,2.4,3.2,4.0 kW)下表层的显微组织、硬度及耐磨性能。结果表明:当激光功率为1.6,2.4 kW时,35CrMo钢表层组织中存在未溶铁素体,硬度比基体低,与GCr15钢对磨后的磨损质量变化率与基体几乎相同,耐磨性较差;当激光功率为3.2,4.0 kW时,表层组织全部为回火马氏体,平均硬度可以达到640 HV,比常规水冷淬火后的硬度提高约20%;当激光功率为3.2 kW时,磨损质量变化率最小,表面未发现明显的磨损痕迹,与基体相比耐磨性得到显著提高,而当激光功率提高到4.0 kW时较高的马氏体自回火程度导致硬度与耐磨性比激光功率为3.2 kW时略有降低。

Laser surface engineering of copper with chromium for enhanced wear resistance

[J].

Application of laser quenching in surface hardening treatment of drill pipe joint thread

[J].

激光淬火技术在钻杆接头螺纹表面硬化处理的应用

[J].

Microstructure and mechanical properties of Ti-35Nb-2Ta-3Zr alloy by laser quenching

[J].

Surface laser quenching as an alternative method for conventional quenching and tempering treatment of 1538 MV steel

[J].

Microstructure and properties of 45 steel after laser transformation hardening and induction heating surface hardening

[J].

45钢激光相变硬化和感应加热表面淬火硬化后的组织和性能

[J].

Effect of laser hardening technical parameters on hardened depth of 40Cr steel

[J].

激光淬火工艺参数对40Cr钢淬硬层深的影响

[J].

Effect of quench-tempering and laser quenching on the microstructure and properties of high-chromium cast iron

[J].

Effect of tempering temperature on the microstructure and properties of ultrahigh-strength stainless steel

[J].The microstructure, precipitation and mechanical properties of Ferrium S53 steel, a secondary hardening ultrahigh-strength stainless steel with 10% Cr developed by QuesTek Innovations LLC, upon tempering were studied by scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), and tensile and impact tests. Based on these results, the influence of the tempering temperature on the microstructure and properties was discussed. The results show that decomposition occurred when the retained austenite was tempered above 440 °C and that the hardening peak at 482 °C was caused by the joint strengthening of the precipitates and martensite transformation. Due to the high Cr content, the trigonal M7C3 carbide precipitated when the steel was tempered at 400 °C, and M7C3 and M2C (5-10 nm in size) coexisted when it was tempered at 482 °C. When the steel was tempered at 630 °C, M2C and M23C6 carbides precipitated, and the sizes were greater than 50 nm and 500 nm, respectively, but no M7C3 carbide formed. When the tempering temperature was above 540 °C, austenitization and large-size precipitates were the main factors affecting the strength and toughness.

Temperature field computation for a rotating cylindrical workpiece under Laser quenching

[J].

Microstructure refinement and properties of 1.0C-1.5Cr steel in a duplex treatment combining double quenching and laser surface quenching

[J].

Wear and corrosion resistance of laser surface hardened structural steel

[J].

Effect of laser power on quenched microstructure and friction and wear properties of 40CrNiMoA steel

[J].The surface layer of the coiled spindle main shaft 40 CrNiMoA steel base material was tested by laser-quenching with different power. The macroscopic structure of cross-section,surface microstructure,microhardness,and friction and wear properties of the specimens were observed or tested by means of stereo microscope,optical microscope,microhardness tester,vertical universal friction and wear tester.The results show that,the surface structure of the laser hardened specimens at different powers exhibit different levels of refining,and compared with the matrix,the hardness and friction and wear properties are improved. When the power is 1600 W,the laser hardened layer can be clearly observed in the cross-section of the specimens,and the surface layer of the specimens is the most detailed,consisting of fine acicular martensite,a small amount of retained austenite and a finely distributed fine carbide,and the surface hardness can reach 640.3-706.8 HV0.2,which is about 2.8 times of that of the substrate. At the same time,the friction coefficient is stable between 0.40 and 0.60,which is about 50% lower than that of the substrate. The amount of wear is 1.3 mg,which is only 36.1% of the substrate. Under the test conditions of spot size with 12 mm×2 mm,scanning speed with 20 mm/s and laser power with 1600 W,the obtained microstructure and friction and wear properties are optimized after surface laser quenching of 40 CrNiMoA steel.

激光功率对40CrNiMoA钢表面淬火组织和摩擦磨损性能的影响

[J].

Effect of quenching and partitioning process on microstructure and properties of Mn-Si-Cr steel

[J].

Improved laser surface hardening of AISI 4130 low alloy steel with electrophoretically deposited carbon coating

[J].

Investigation into the efficiency of a fiber laser in surface hardening of ICD-5 tool steel

[J].

Microstructure and properties of Cr12MoV die steel by laser quenching with different power

[J].

Study on microstructure and properties of 32CrNi3MoVE steel by laser surface quenching

[J].

32CrNi3MoVE钢激光表面淬火显微组织和性能研究

[J].

Superior resistance to hydrogen damage for selective laser melted 316L stainless steel in a proton exchange membrane fuel cell environment

[J].

Wear and corrosion behavior of laser surface engineered AISI H13 hot working tool steel

[J].

Corrosion properties of quenching-partitioning-tempering steel in simulated seawater

[J].

淬火-配分-回火钢在模拟海水环境中的腐蚀性能研究

[J].利用XRD、SEM和TEM等测试方法研究了淬火-配分-回火 (Q-P-T) 钢热处理后的物相结构和显微组织形貌,并以相同成分的淬火-回火 (Q&T) 钢和不含碳化物的淬火-配分 (Q&P) 钢为参照,利用失重法、电化学测试等方法研究了Q-P-T钢在模拟海水环境3.5% (质量分数) NaCl溶液中的腐蚀行为。结果表明,Q&T钢内的残余奥氏体主要以薄膜状分布在马氏体板条间,其含量低于3% (体积分数),而Q&P钢和Q-P-T钢内的残余奥氏体则以薄片状分布在马氏体板条间,其平均含量分别为15.35% (体积分数) 和14.6% (体积分数);含碳化物的Q-P-T钢的耐蚀性优于不含碳化物的Q&P钢,且经配分的Q-P-T和Q&P钢的耐蚀性能稍优于Q&T钢。4种钢表面腐蚀产物的演变规律基本一致,即初期腐蚀产物以β-FeOOH和γ-FeOOH为主,随浸泡时间的延长,逐渐以α-FeOOH和Fe<sub>3</sub>O<sub>4</sub>为主;4种试样腐蚀表面初期均分布着尺寸不一的点蚀坑,随浸泡时间的延长,逐渐变为均匀腐蚀。

Research on the correlation between impact toughness and corrosion performance of Cr13 super martensitic stainless steel under deferent tempering condition

[J].

Influence of Cr content on characteristics of corrosion product film formed on several steels in artifitial stratum waters containing CO2-H2S-Cl-

[J].

CO2-H2S-Cl-共存的地层水环境中Cr含量对钢的腐蚀产物膜特性的影响

[J].采用带有电磁驱动轴的高温高压釜,通过失重法评价了L80、L80Cr13、22Cr、25Cr钢在含CO<sub>2</sub>、H<sub>2</sub>S、Cl<sup>-</sup>的地层水中的腐蚀速率,采用SEM、EDS及XRD对其表面腐蚀产物膜进行了分析,利用AFM分析腐蚀后材料表面的粗糙度,使用CLSM分析腐蚀后材料表面的点蚀情况。结果表明,在CO<sub>2</sub>分压为0.12 MPa、H<sub>2</sub>S分压为0.003 MPa,Cl<sup>-</sup>浓度为150.8 g/L,温度为80 ℃的地层水中,试样转速为100 r/min的条件下,4种钢材均匀腐蚀速率由大到小排序为L80Cr13>L80>22Cr>25Cr。L80Cr13钢表面的腐蚀产物膜主要是由Cr<sub>2</sub>O<sub>3</sub>与Cr(OH)<sub>3</sub>组成,该腐蚀产物膜在Cl<sup>-</sup>的作用下局部地方破损;L80Cr13钢发生了明显的点蚀,最大点蚀深度为11.037 μm。L80钢表面的腐蚀产物膜主要是由FeS以及疏松的FeCO<sub>3</sub>组成,该产物膜对L80钢具有一定的保护作用,但L80钢仍旧有轻微的点蚀,最大点蚀深度为1.855 μm。22Cr、25Cr钢表面仅有一层钝化膜,且该钝化膜对基体具有良好的保护作用,基体几乎没有发生点蚀。

Unmasking of the temperature window and mechanism for “loss of passivation” effect of a Cr-13 type martensite stainless steel

[J].

Corrosion behaviour of a quenched and partitioned medium carbon steel in 3.5 wt.% NaCl solution

[J].

Research on tool wear morphology and mechanism during turning nickel-based alloy GH4169 with PVD-TiAlN coated carbide tool

[J].

On the optical microscopic method for the determination of ball-on-flat surface linearly reciprocating sliding wear volume

[J].

Characterization of air-formed surface oxide film on a Co-Ni-Cr-Mo alloy (MP35N) and its change in Hanks’ solution

[J].

The dry wear of steels II. Interpretation and special features

[J].

A study of friction-induced martensitic transformation for austenitic manganese steel

[J].