近年来我国环保领域对超奥钢需求量越来越大,同时也对超奥钢性能提出了更高要求,微合金化是抑制超奥钢中析出相析出的有效方法。已有研究表明微合金化元素B、Cu、N、Ce等加入高钼奥氏体不锈钢中,可对其析出相的析出产生影响。如超级奥氏体不锈钢中添加微量B,能够起到降低晶界能,抑制有害第二相的析出的作用[5],主要是由于B可偏析于晶界,从而抑制Mo向晶界偏聚[6]。N可提高S32654超奥钢的稳定性,抑制晶界Sigma相的形成[7]。Cu的添加可以改善超奥钢表面钝化膜的稳定性,进而提升材料的耐腐蚀性能[8]。研究表明,添加适量Ce能够提高316L不锈钢在NaCl溶液中的腐蚀电位,降低其腐蚀电流密度,增大容抗弧半径,提高耐蚀性能[9]。此外,适量的Ce能够细化第二相组织,抑制Sigma等的析出[10-12]。

Ce对S31254超级奥氏体不锈钢凝固组织的影响已有研究,但是其对析出相析出行为的影响报道还很少,Ce对S31254不锈钢析出相和耐蚀性能的影响值得进一步研究。本文在S31254超级奥氏体不锈钢中加入微量Ce,探讨其对析出相析出的影响规律,并研究热处理工艺对析出相、耐蚀性的影响。

1 实验方法

实验材料为Ce微合金化S31254不锈钢,其合金成分 (质量分数,%) 为:C 0.012、Si 0.61、Mn 0.93、P 0.01、S 0.002、Cr 20.17、Ni 18.15、Mo 6.03、Cu 0.72、N 0.212、Ce 0.004、Fe余量。实验所用试样规格为10 mm×10 mm×3 mm。热轧态S31254-Ce经1250 ℃固溶处理60、120、180 min后水冷。对固溶处理后试样进行时效处理,工艺为800~900 ℃×30~120 min,水冷。热处理均在管式热处理炉中进行。

用JSM-7900F型扫描电镜 (SEM) 对试样的微观组织进行分析,研究析出物的析出位置、形态、大小和数量,使用JSM-7900F型能谱仪 (EDS) 对析出物进行成分分析。采用动电位极化法和电化学阻抗谱测试 (EIS) 研究时效试样的抗点蚀性能。使用CS310H型电化学工作站在三电极体系中对S31254-Ce不锈钢进行电化学测量,时效试样作为工作电极 (WE),铂电极作为辅助电极 (CE),饱和甘汞电极作为参比电极 (SCE) 。实验所用腐蚀介质为10% (质量分数) NaCl溶液,溶液温度保持在25 ℃。用Tafel公式对动电位极化曲线进行拟合,并计算极化曲线相关参数。使用Zsimp Win软件对电化学阻抗参数进行拟合分析。

2 结果与讨论

2.1 微观组织分析

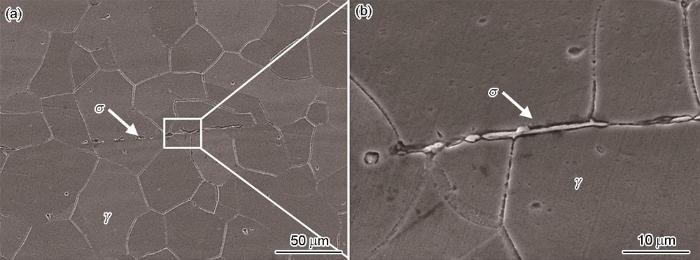

图1为S31254-Ce不锈钢热轧态试样的微观组织。可以观察到热轧态试样轧制痕迹明显,第二相沿着轧制方向析出,轧制变形量大的区域析出相较多,析出相主要沿轧制方向的晶界析出,呈断续条带状。热轧试样的晶粒尺寸并不均匀,晶粒尺寸在20~50 μm之间。

图1

图1

S31254-Ce不锈钢轧制态显微组织

Fig.1

As rolled microstructure of S31254-Ce stainless steel: (a) low image, (b) high image

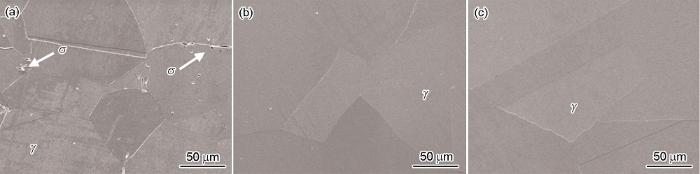

对S31254-Ce不锈钢试样进行1250 ℃固溶处理,保温分别为60、120、180 min,淬水后得到的微观组织如图2所示。整体来看,保温时间越长,析出相越少。固溶60 min处理后,S31254-Ce中析出相已基本回溶,但轧制带区域仍有一定量析出相;120 min保温后,试样晶界处析出相完全回溶,原来轧制带依稀可见,析出相已基本观察不到,为单一的奥氏体组织,晶粒尺寸略有长大。180 min保温后,试样晶界处析出相完全回溶,原来轧制带已经无法分辨清楚,为单一的奥氏体组织。此时析出相对晶界的钉扎作用已完全消失,故晶粒尺寸明显长大。由此可见晶粒尺寸的长大与析出相回溶程度密切相关。析出相析出过程也和析出相回溶程度有关。析出相回溶完全后,元素在基体中的分布更加均匀,而析出相回溶不完全时,析出相易从原来位置快速析出。因此,选取1250 ℃保温120 min,析出相已经完全回溶的S31254-Ce不锈钢试样进行后续时效处理。

图2

图2

S31254-Ce经1250 ℃固溶处理不同时间后显微组织

Fig.2

Microstructure of S31254-Ce stainless steel after solution treatment at 1250 ℃ for 60 min (a), 120 min (b) and 180 min (c)

2.2 时效处理后显微组织

2.2.1 温度对析出相的影响

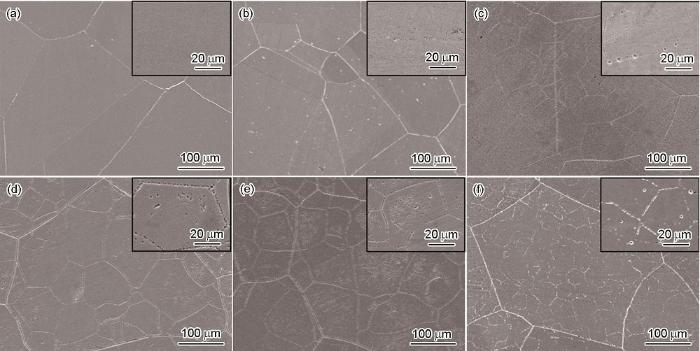

图3为S31254-Ce不锈钢在800 ~ 900℃不同温度下分别时效90 min后试样的微观组织。可以看出,时效温度较低时,S31254-Ce中第二相易析出于晶内位置,时效温度提高后,第二相更易沿晶界析出。当时效温度达到840 ℃后,S31254-Ce中第二相析出速度加快,晶内析出相逐步呈网络状分布。

图3

图3

S31254-Ce超级奥氏体不锈钢不同温度时效保温90 min后显微组织

Fig.3

Microstructure of S31254-Ce stainless steel treated at 800 ℃ (a), 820 ℃ (b), 840 ℃ (c), 860 ℃ (d), 880 ℃ (e) and 900 ℃ (f) aging temperatures for 90 min

具体来看,温度为800 ℃时,析出相主要析出于晶界,呈细小点状断续分布,晶内几乎观察不到析出相;820 ℃时,晶界处析出相逐渐增多,呈短条状沿晶界断续分布,晶内开始出现少量的细小颗粒状析出相;840 ℃时,晶界处析出相数量进一步增加,同时,晶内颗粒状析出相明显增多,呈间断网络状分布;温度为860 ℃时,试样中析出相的析出速度加快。晶界处第二相数量增加,沿晶界呈条状连续分布,宽度较窄。晶内颗粒状析出相数量进一步增加,呈连续网络状分布;880 ℃时,试样中析出相的析出速度进一步提高。晶界处连续分布的条状析出相宽度增加。晶内析出相呈连续网状分布,并且网状结构内部也出现了细小颗粒状析出;时效温度提高至900 ℃,析出相的析出速度略减缓,析出相主要沿晶界分布。与880 ℃时效试样相比,晶界析出相宽度增幅较小。而此时晶内呈网状分布的小颗粒析出相数量略有减少。这是因为析出相的析出行为与温度、元素分布等因素相关。时效温度低时,Cr、Mo等析出相形核、长大所需的元素扩散速度慢,就近扩散到邻近区域,此时析出相易在晶粒内部析出并生长。当时效温度较高时,元素扩散能力加强,Mo、Cr等元素更易快速扩散到晶界;此外,Mo、Cr等溶质原子在晶界处易出现成分起伏与结构起伏,导致晶界处形核位垒较低,高温使得析出相形核驱动力增大,故析出相也更倾向于在晶界处形核析出。观察图3f可知,900 ℃时效处理后,S31254-Ce不锈钢试样中析出相更容易沿晶界析出,而晶内位置析出相数量反而减少。

2.2.2 时间对析出相的影响

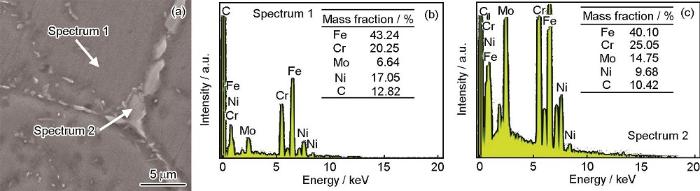

从图3来看,S31254-Ce不锈钢在860 ℃下进行时效处理时,试样的晶内析出相由细小颗粒组成,呈网状分布。为此对S31254-Ce不锈钢进行860 ℃不同时间的时效处理,并对析出相的析出行为进行分析。图4为S31254-Ce不锈钢在860 ℃温度下分别时效30、60、90、120 min试样的微观组织。可看到随时效时间延长,试样中析出相数量逐渐增加,但当时效时间延长至90 min,析出相析出速率放缓。具体来看,时效30 min时,析出相主要沿晶界析出,晶内分布着细小颗粒状析出相,但数量很少;时效60 min时,晶界析出相呈断续分布,数量逐渐增多,尺寸长大;晶粒内部细小颗粒状析出相数量增加,个别颗粒状析出相尺寸略有长大;当时效达90 min后,晶界析出相越来越多,晶内颗粒状析出相呈现出网状分布;时间延长至120 min,晶界处析出相呈条状连续分布;晶内颗粒状析出相仍以网络状沿着晶界分布,数量略有增加。总体来看,经长时间时效处理后,试样中析出相析出速度减缓,应该受该温度下析出相的C曲线所影响。对860 ℃时效处理120 min后的S31254-Ce不锈钢试样进行EDS分析,由能谱图 (图5) 可知,析出相与基体相比Cr、Mo含量较高。

图4

图4

S31254-Ce不锈钢860 ℃时效处理不同时间后显微组织

Fig.4

Microstructure of S31254-Ce stainless steel treated at 860 ℃ for 30 min (a), 60 min (b), 90 min (c) and 120 min (d)

图5

图5

S31254-Ce不锈钢860 ℃时效处理120 min后显微组织及EDS分析

Fig.5

Morphology (a) and EDS analysis (b, c) of S31254-Ce stainless steel aged at 860 ℃ for 120 min

2.3 耐蚀性能分析

图6

图6

S31254-Ce不锈钢经固溶及不同时效温度处理90 min后的动电位极化曲线及Icorr值随时效温度变化

Fig.6

Potentiodynamic polarization curves (a) and Icorr value change of S31254-Ce stainless steel solution treated and aged at different aging temperatures for 90 min (b)

表1 S31254-Ce不锈钢经固溶及不同时效温度处理90 min后动电位极化相关参数

Table 1

| Temperature / ℃ | Icorr / 107 A·cm-2 | Ecorr / V | Ip / 105 A·cm-2 | Epit / V |

|---|---|---|---|---|

| Solution treatment | 2.11±0.055 | -0.148 | 6.22 | 1.137 |

| 800 | 2.14±0.036 | -0.149 | 6.31 | 1.104 |

| 820 | 3.25±0.083 | -0.182 | 8.44 | 1.097 |

| 840 | 5.06±0.074 | -0.249 | 14.37 | 1.059 |

| 860 | 9.39±0.078 | -0.373 | 27.54 | 1.038 |

| 880 | 12.42±0.063 | -0.463 | 35.55 | 1.021 |

| 900 | 13.18±0.083 | -0.534 | 52.14 | 1.011 |

可以观察到,S31254-Ce不锈钢试样在固溶处理后,其Icorr最小,即此时试样的腐蚀速率最小,具有良好的耐蚀性能。随时效温度提高,试样的Icorr值不断升高,试样的腐蚀速率加快,耐蚀性能也随之下降。当时效温度为840~900 ℃时,试样腐蚀电流密度上升幅度更大。点蚀电位 (Epit) 代表试样在腐蚀过程中钝化膜被击穿时的电位[15],点蚀电位越高,则材料所形成的钝化膜更加稳定。结合文献[16],S31254超奥钢经固溶处理后,相同腐蚀环境下 (10%NaCl),其Epit值在0.95~0.97 V之间,本实验S31254-Ce不锈钢固溶处理后试样的Epit值为1.137 V,说明Ce可提高S31254的耐蚀性能。时效温度为800~840 ℃时,试样的点蚀电位小幅度下降。当时效温度提高至840~900 ℃时,点蚀电位下降幅度增大。此外,固溶试样的Ipass最低,表明此时钝化膜具有较好稳定性,试样耐蚀性能较好。同样地,随着时效温度提高,试样中Ipass值升高,并且在840 ℃以上时效处理时,Ipass升高幅度明显增大,材料的耐蚀性能也明显恶化。

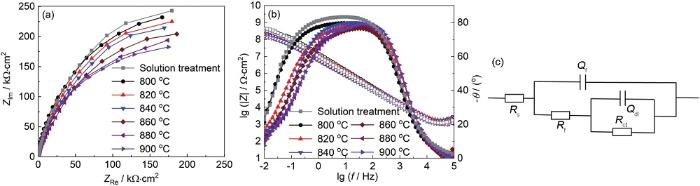

S31254-Ce不锈钢在不同时效温度保温90 min后的EIS曲线如图7所示。图7a中Nyquist图显示,所有的测试曲线都呈现相同的半圆形容抗弧特征,这表明不同时效温度处理下,S31254-Ce具有类似的腐蚀机制[16]。Nyquist曲线中的容抗弧直径代表着材料在电化学腐蚀过程中电阻的大小[17],其直径越大,则材料的耐蚀性能越好。S31254-Ce不锈钢固溶处理后试样的容抗弧直径最大,获得了最佳的耐蚀性能。时效温度较低时 (800~840 ℃),样品的容抗弧直径小幅度下降。时效温度较高时 (840~900 ℃),样品容抗弧直径下降幅度更大,其抗点蚀性能明显下降。当时效温度达到900 ℃时,样品的容抗弧直径最小,此时试样的耐蚀性能最差,900 ℃时效试样的容抗弧半径与880 ℃相近,对比来看,析出相的数量、分布对阻抗的影响很明显。

图7

图7

S31254-Ce不锈钢经固溶及不同时效温度处理90 min后EIS曲线及等效电路

Fig.7

Nyquist (a) and Bode (b) plots and EIS equivalent circuit diagram (c) of S31254-Ce stainless steelsolution treated and aged at different aging temperatures for 90 min

图7b为S31254-Ce不锈钢在不同时效温度处理下的Bode曲线。Bode曲线通常用于说明材料阻抗模量及相位角随频率的变化[18],低频区域的阻抗模量值大小能够直观反映材料的耐蚀性能,其阻抗值越大,则材料的耐点蚀性能越好;而中频区域的相位角大小能够反映材料钝化膜的稳定性[17,18],其相位角越大,即材料的钝化膜稳定性越高。可以观察到,所有的测试曲线从低频到中频区域的相位角接近90°,这表明各试样在测试中均形成了稳定的钝化膜。此外,图7b显示,在低频区域,固溶试样的阻抗模量|Z|值大于其他样品,表明此时试样的耐点腐蚀性最佳。而900 ℃时效试样在低频区域的|Z|值与880 ℃时效后试样相差不大。这些观察结果与动电位极化曲线测试的结果相一致。

表2 S31254-Ce不锈钢经固溶及不同时效温度处理90 min后等效电路拟合结果

Table 2

| Temperature / ℃ | Rs / Ω·cm2 | Rct / Ω·cm2 | Qct / 10-5 Ω-1·cm-1s-1 | nct | Rf / kΩ·cm2 | Qf / 10-5 Ω-1·cm-1s-1 | nf |

|---|---|---|---|---|---|---|---|

| Solution treatment | 10.41 | 2138.77 | 7.18 | 0.89 | 344.61 | 5.04 | 0.88 |

| 800 | 10.57 | 2057.56 | 7.24 | 0.89 | 332.85 | 5.18 | 0.90 |

| 820 | 10.53 | 1935.78 | 7.70 | 0.89 | 319.59 | 5.64 | 0.91 |

| 840 | 10.38 | 1781.43 | 8.38 | 0.90 | 249.81 | 7.27 | 0.89 |

| 860 | 10.32 | 1149.74 | 9.04 | 9.91 | 131.26 | 8.35 | 0.90 |

| 880 | 10.61 | 796.23 | 9.77 | 0.83 | 104.72 | 9.26 | 0.88 |

| 900 | 10.86 | 520.65 | 10.06 | 0.85 | 85.77 | 9.92 | 0.87 |

R值能够反映材料在电化学腐蚀过程中所形成钝化膜的稳定性,高的R值代表材料有着良好的耐蚀性能。S31254-Ce不锈钢经固溶处理后,其钝化膜电阻 (Rf) 和电荷转移电阻 (Rct) 明显高于时效处理后的试样,结合图7,固溶处理后的S31254-Ce不锈钢具有较佳的耐蚀性能。随时效温度升高,S31254-Ce不锈钢的Rf和Rct值逐渐下降,并且时效温度高于840 ℃时,Rf和Rct值下降幅度更大。而Q值则能够反映材料钝化膜中的缺陷数量,Q值越低,则缺陷数量越少,钝化膜更加致密。由表2可知,S31254-Ce不锈钢固溶试样具有最低的Q值,即此时材料中形成钝化膜稳定性高。同样,时效温度高于840 ℃时,S31254-Ce不锈钢中Q值增加幅度较大。

经不同时效温度处理后,S31254-Ce不锈钢的耐蚀性有较大的变化,这与时效过程中析出相析出的数量、大小、位置直接相关。下面结合S31254-Ce不锈钢时效后微观组织,对其耐蚀性进行分析。由图2a~c可知,在840 ℃以下温度时效处理时,S31254-Ce不锈钢中析出相的数量较少,尺寸也小,此温度范围对应的耐蚀性较好,即少量的析出相对S31254-Ce耐蚀性的影响小;当高于840 ℃时效处理时 (图2d~f),晶界析出相继续析出,逐渐连成网状,数量增多的同时宽度增大,且晶内析出相的数量明显增加、尺寸逐渐增大。本研究中的析出相为高Cr、Mo含量的第二相,析出相尺寸的增加也会导致Cr、Mo富集的程度加重,进而造成邻近区域Cr、Mo含量降低,即基体与析出相相界面处易出现贫Cr、贫Mo区。这些贫Cr、贫Mo区域的耐蚀性很差,会导致S31254-Ce不锈钢的腐蚀速率加快[23]。由组织来看 (图2e,f),880 ℃、900 ℃时效处理后,S31254-Ce不锈钢中析出相数量均很多,故耐蚀性均较差。已有研究结果表明,S31254时效后析出相中Cr含量 (26%~27%)、Mo含量 (19%~21%) 均较高[5,17],本研究中S31254-Ce不锈钢的析出相中,Cr含量 (25.05%) 与S31254不锈钢析出相接近,而Mo含量 (14.75%) 略低,由此来看铈的添加有利于延缓析出相周边的贫Mo区域,改善耐蚀性。

3 结论

(1) 1250 ℃下固溶处理120 min后,S31254-Ce不锈钢中析出相可完全回溶,为固溶处理的较佳工艺参数。S31254-Ce不锈钢经800~900 ℃时效处理后,温度越高析出相数量越多,第二相优先析出于晶界,当温度高于840 ℃时,析出相在晶内位置也逐渐析出。

(2) S31254-Ce不锈钢于860 ℃进行时效处理,随时效时间延长,晶界析出相由断续条状,渐渐演变为连续条状沿晶界析出。晶内细小点状析出相逐渐长大,构成连续的网状结构。

(3) S31254-Ce不锈钢具有最好的耐蚀性。随时效温度提高,析出相越多,S31254-Ce不锈钢的耐蚀性能越弱。当时效温度为840~900 ℃时,材料耐点蚀性能的逐渐变差。这与S31254-Ce时效过程中第二相的数量、大小、分布密切相关。在840~900 ℃时效温度处理下,第二相析出的数量明显增多、尺寸增大,且第二相邻近的相界面易产生Cr、Mo贫化区,进而成为材料腐蚀的薄弱位置,导致试样的腐蚀速率增加,耐点蚀性能明显下降。

参考文献

Effect of B addition on the microstructure and corrosion resistance of S31254 super austenitic stainless steels after solid solution treatment

[J].

Effects of Cr and Mo on precipitation behavior and associated intergranular corrosion susceptibility of superaustenitic stainless steel S32654

[J].

Microstructure evolution in the segregation area of S31254 stainless steel plate

[J].

Precipitation behavior and phase transformation mechanism of super austenitic stainless steel S32654 during isothermal aging

[J].

Effect of boron addition on the precipitation behavior of S31254

[J].

Effects of B on the segregation of Mo at the Fe-Cr-NiΣ5 (210) grain boundary

[J].

Influence of N on precipitation behavior, associated corrosion and mechanical properties of super austenitic stainless steel S32654

[J].The influence of N on the precipitation behavior, associated corrosion, and mechanical properties of S32654 were investigated by microstructural, electrochemical, and mechanical analyses. Increasing the N content results in several alterations: (1) grain refinement, which promotes intergranular precipitation; (2) a linear increase in the driving force for Cr2N and Mo activity, which accelerates the precipitation of intergranular Cr2N and π phase, respectively; (3) a linear decrease in the driving force for σ phase and Cr activity, which suppresses the formation of intragranular σ phase. The total amount of precipitates first decreased and then increased with the N content increasing. Furthermore, the intergranular corrosion susceptibility depended substantially on the total amount of precipitates and also first exhibited a decreasing and then an increasing trend as the N content increased. In addition, aging precipitation caused a considerable decrement in the ultimate tensile strength (UTS) and a remarkable increment in the yield strength (YS). Both the UTS and YS always increased with N content increasing throughout the solution and aging process. Whereas the elongation was considerably sensitive to the aging treatment, it exhibited marginal variation with the N content increasing.

Copper alloying content effect on pitting resistance of modified 00Cr20Ni18Mo6CuN super austenitic stainless steels

[J].

The effect of cerium solutions on 316L stainless steel

[J].

Refinement mechanism of cerium addition on solidification structure and sigma phase of super austenitic stainless steel S32654

[J].The influence of Ce addition on the solidification structure and σ phase of super austenitic stainless steel S32654 was systematically investigated via microstructural characterization and thermodynamic calculation. The results indicate that a small addition of Ce could modify MgO and MnS into Ce-bearing inclusions Ce2O3 and Ce2O2S. Ce addition led to noticeable refinement of both the dendrite structure and σ phase. The refinement mechanism could be attributed to the combined actions of effective Ce-bearing inclusions and solute Ce. Effective Ce-bearing inclusions could serve as heterogeneous nucleation cores of austenite as well as σ phase, which provided a favorable prerequisite for their refinement. Solute Ce significantly enhanced the undercooling degree of the system, further promoting dendrite structure refinement. Meanwhile, solute Ce improved the eutectic precipitation conditions of σ phase and further promoted its nucleation, while the dendrite refinement limited its growth space. Finally, more fine and dispersed σ phase particles formed in S32654 with Ce addition. The refinement of dendrite structure and σ phase will reduce the temperature and time required for high-temperature homogenization, which is beneficial to the hot working of this steel.

Effect of cerium on the austenitic nucleation and growth of high-Mo austenitic stainless steel

[J].

Effect of Ce addition on secondary phase transformation and mechanical properties of 27Cr-7Ni hyper duplex stainless steels

[J].

Effect of boron on dissolution and repairing behavior of passive film on S31254 super-austenitic stainless steel immersed in H2SO4 solution

[J].

Enhanced irradiation and corrosion resistance of 316LN stainless steel with high densities of dislocations and twins

[J].

Effect of temperature on pitting corrosion behavior of 316L stainless steel in oilfield wastewater

[J].

温度对316L不锈钢在油田污水中点蚀行为的影响研究

[J].

Effect of solution treatment on the microstructure and performance of S31254 super austenitic stainless steel

[J].

Pitting corrosion behavior of 304 stainless steel in simulated concrete pore solutions

[J].

304不锈钢在模拟混凝土孔隙液中的点蚀行为研究

[J].

EIS study of potentiostatically formed passive film on 304 stainless steel

[J].

Correlation between predictive and descriptive models to characterize the passive film-Study of pure chromium by electrochemical impedance spectroscopy

[J].

Improved corrosion performance of selective laser melted stainless steel 316L in the deep-sea environment

[J].

Influence of temperature on the electrochemical and passivation behavior of 2507 super duplex stainless steel in simulated desulfurized flue gas condensates

[J].

Equivalent electrical circuits fitting of electrochemical impedance spectroscopy for rebar steel corrosion of coral aggregate concrete

[J].

等效电路拟合珊瑚混凝土中钢筋锈蚀行为的电化学阻抗谱研究

[J].