吉林油田是一个老油田,位于吉林省松原市,始建于1961年,为了提高采收率采用了CO2注入驱油技术。然而,CO2注入导致下游设备发生腐蚀[12],其在长期注入开采过程中还会产生次生的H2S,进一步加重腐蚀。油管钢服役环境属于典型的H2S与CO2共存环境。相关调查表明,随着注水开采时间的延长,原油含水率达到约85%,腐蚀可能已经发生并进入了快速发展阶段。高含水率、CO2以及次生H2S等多重因素的协同作用极易引发腐蚀,大大加速油管钢的腐蚀速率,甚至提高受力管段和部件的硫致SCC风险[13,14,15],极大程度上影响油套管的服役寿命。因此,有必要对吉林油田环境中服役的油管钢开展腐蚀行为调查,对其腐蚀机理进行分析,同时结合室内腐蚀电化学技术和慢应变速率拉伸实验,判断其SCC开裂倾向,为油管钢在吉林油田的安全服役提供相应的理论依据和技术支撑。

本工作利用体式显微镜、扫描电子显微镜 (SEM) 手段,结合现场工况条件,对现场服役过的L80油管钢内外壁腐蚀行为进行了对比分析,通过电化学阻抗谱、极化曲线测量和慢应变速率拉伸实验研究了L80钢在模拟油田采出水环境中的电化学和SCC行为。

1 实验方法

1.1 实验材料

实验材料为CO2驱油区块某采油井中服役过一段时间的L80油套管钢,其化学成分 (质量分数,%) 为:C 0.29,S 0.001,P 0.007,Si 0.21,Mn 1.32,Cu 0.09,Fe余量。利用线切割切取一端面积为1 cm×1 cm的块状试样,并通过砂纸逐级打磨,然后抛光和酒精清洗,接着用4% (体积分数) 硝酸进行刻蚀,金相组织照片见图1。可以看出,L80油管钢的晶粒细小均匀,主要由针状铁素体和少量多边形铁素体组成,并未观察到较大尺寸的夹杂物。

图1

1.2 带锈油管腐蚀行为分析

将L80油管钢带锈试样置于VHX-2000体式显微镜和Quanta 250 型SEM下观察其锈层形貌,同时采用EDAX Elite T型能谱仪 (EDS) 对锈层成分进行鉴定。随后,利用除锈液 (500 mL H2O+500 mL HCl+4~10 g六次甲基四胺) 超声去除表面腐蚀产物,利用SEM和体视显微镜分别对其表面腐蚀形貌和点蚀深度进行分析。

1.3 室内电化学测量

利用传统的三电极体系在P2273型电化学工作站上进行电化学阻抗谱和极化曲线测量,其中L80钢为工作电极,Pt片为对电极,饱和甘汞电极 (SCE) 为参比电极。试样尺寸为10 mm×10 mm×3 mm,工作面积为1 cm×1 cm。测量之前先将试样用环氧树脂密封,将工作面用砂纸逐级打磨至2000#,然后置于腐蚀环境中30 min,获得稳定的开路电位。阻抗谱的激励电位为10 mV,扫描范围为105~10-2 Hz。极化曲线电位扫描区间为-1.2~0 VSCE,扫描速率为0.5 mV/s。每组电化学曲线测量3次以确保其准确性。电化学测试环境为不同含水率、CO2和H2S分压下的油田腐蚀环境模拟液,实验温度为80 ℃,含水率分别为30%和80%,CO2分压分别为0,0.5和1.1 MPa,H2S分压分别为0,0.03和0.15 MPa,其中总压为10 MPa。

1.4 室内慢应变速率拉伸实验

利用慢应变速率拉伸实验研究了L80钢在上述模拟油井采出液下的SCC行为和敏感性,模拟溶液成分与电化学测试溶液保持一致。采用标准的片状拉伸试样,其中间工作段长度为30 mm,宽度和厚度分别为6和2 mm。为了更好地模拟已服役过的L80钢的力学性能,先将试样置于油田采出液腐蚀环境中720 h,然后取出试样进行实验。其中一组试样直接在空气中拉伸,其它试样分别在各自的腐蚀液中拉伸。实验前先将试样置于500 N预加载力维持24 h以便避免夹具间缝隙,随后开始实验直至试样断裂。拉伸速率为1×10-6 s-1,每组曲线测量3次以确保其准确性。

2 结果与讨论

2.1 L80钢腐蚀产物成分

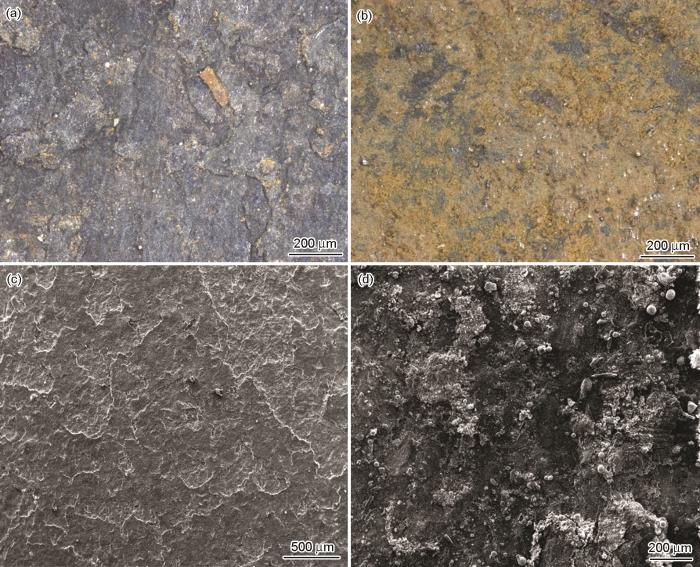

图2

图2

L80油管钢表面腐蚀产物形貌照片

Fig.2

Optical microscopy (a, b) and SEM (c, d) images of corrosion products formed on the outer (a, c) and inner (b, d) walls of L80 tubing steel

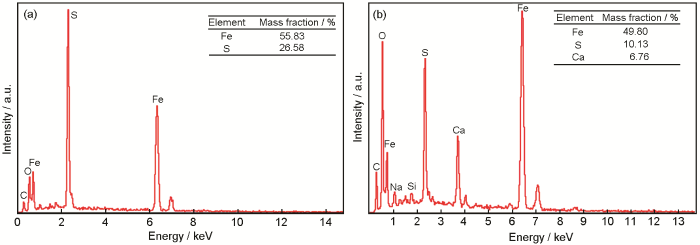

图3

图3

L80油管钢腐蚀产物EDS分析结果

Fig.3

EDS results of corrosion products formed on the outer (a) and inner (b) walls of L80 tubing steel

2.2 L80钢腐蚀形貌

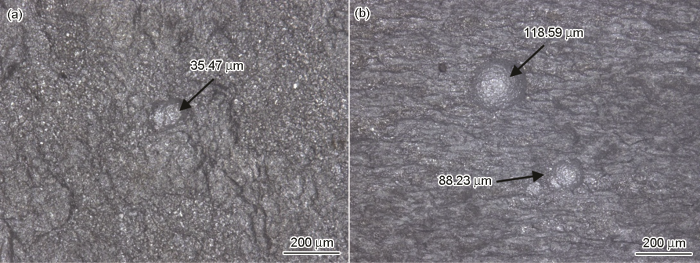

除去表面腐蚀产物后,采用体式显微镜对其表面点蚀坑深度进行检测,如图4所示。从表面形貌可以看出,外壁腐蚀较为一致,以均匀腐蚀为主。表面蚀坑较少,并未观察到较大较深的点蚀坑,所测坑深为35.47 μm。相比之下,L80钢内壁上局部腐蚀程度较为严重,最大蚀坑深度可达118.59 μm,远高于外侧蚀坑的,这是由于腐蚀产物膜的覆盖减缓了均匀腐蚀过程,诱导腐蚀坑的萌生和扩展,相比之下更容易引起SCC。

图4

图4

L80油管钢表面点蚀坑观察

Fig.4

Optical microscopy images of corrosion pits on the outer (a) and inner (b) walls of L80 tubing steel

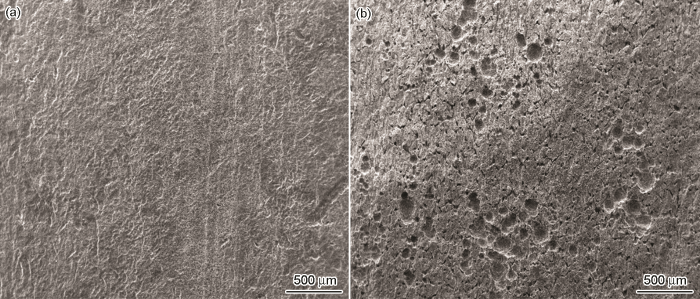

图5

图5

L80油管钢除锈后的腐蚀形貌观察

Fig.5

Corrosion morphologies of the outer (a) and inner (b) walls of L80 tubing steel after the removal of corrosion products

2.3 电化学行为

2.3.1 阻抗谱分析

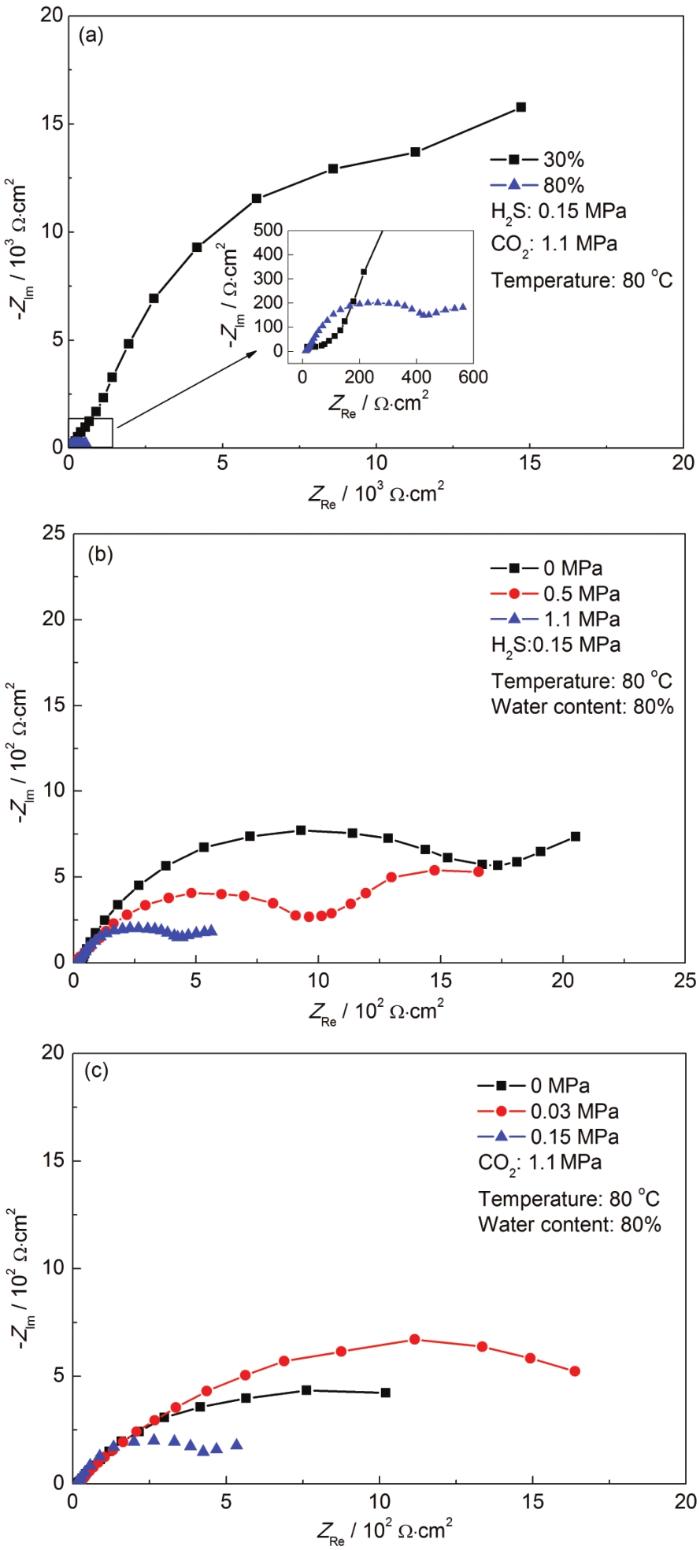

采用不同含水率、CO2和H2S分压条件下的油田腐蚀模拟液对L80钢电化学和SCC行为进行了研究,图6所示即为各种条件下的阻抗谱结果。各种条件下L80钢的阻抗均呈现出两个半圆弧,表明有两个时间常数。由图6a可以看出,含水率对阻抗弧半径产生显著的影响,当含水率从30%增加到80%,其阻抗弧半径从15000 Ω·cm2降到了600 Ω·cm2,表明其耐蚀性急剧下降。相比含水率,CO2和H2S分压的改变对阻抗的影响较低。当CO2分压从0 MPa增加到0.5 MPa时,其阻抗值变化较小;而继续增大CO2分压到1.1 MPa时,其阻抗弧半径有一个明显的缩小,体现出腐蚀能力的下降。H2S与上述两种因素不同,当其分压较低时,如0.03 MPa,其阻抗呈现出增大的现象;而继续增加H2S浓度至0.15 MPa时,阻抗弧半径则显著降低。这是因为当H2S浓度较低时,试样表面能够形成一层致密的腐蚀产物膜,为基体提供了一定程度的保护作用,从而增大了其耐蚀性。

图6

图6

L80钢在不同条件下的油田模拟液中的电化学阻抗谱

Fig.6

EIS curves of L80 tubing steels exposed in the simulated solution environments with the different contents of water (a) and the different pressures of CO2 (b) and H2S (c)

2.3.2 极化曲线分析

图7

图7

不同条件下L80钢在模拟油田采出水环境中的极化曲线

Fig.7

Polarization curves of L80 tubing steels exposed in the simulated solution environments with the different contents of water (a) and the different pressures of CO2 (b) and H2S (c)

CO2和H2S分压的改变并未对腐蚀电位产生较大的影响,这在热力学上说明,其耐蚀性并未受到明显的改变,如图7b和c所示,这与EIS分析结果相一致。然而,CO2和H2S的增加对其阴阳极过程也产生了一定的影响,随着CO2的增加,电化学阴阳极过程均呈现出右移的趋势,腐蚀电流密度增大一个数量级,说明其电化学过程得到较大的促进。H2S浓度的增大则呈现出不同的趋势,当浓度仅为0.03 MPa时,电化学阴阳极过程均向左移动,腐蚀电流密度有所下降,表明其电化学过程受到一定程度的抑制;继续增大H2S浓度时,阳极过程依然处于轻微的受抑制状态,而阴极析氢过程有所增加,这与H2S引起的酸化有关。

2.4 实验室内SCC行为分析

为了比较L80钢在不同含水率、CO2和H2S浓度下的油田模拟液中SCC行为,分别在相应环境中进行了慢应变速度拉伸实验,结果如图8所示。可以看出,含水率、CO2和H2S对L80钢的SCC行为均产生了一定的影响,且影响程度有所不同。图8a显示随着含水率的增加,L80钢的强度变化不大,但延伸率有所降低,试样在含80%水的油气开采液环境中表现出一定程度的敏感性。相比之下,无论是CO2浓度升高至1.1 MPa,还是H2S浓度升至0.15 MPa,L80钢的应力-应变曲线几乎与空气中的相重合,延伸率仅有微小的变化。这说明在特定的含水率 (80%) 条件下,L80钢的SCC敏感性受CO2和H2S浓度变化的影响较小,具有较好的抗SCC能力。

图8

图8

不同条件下L80钢在模拟油田采出水环境中的应力应变曲线

Fig.8

Stress-strain curves of L80 tubing steel exposed in the simulated solution environments with the differ-ent contents of water (a) and the different pressures of CO2 (b) and H2S (c)

3 分析与讨论

通过对吉林油田取回的L80油管钢进行腐蚀分析,显示其内外壁腐蚀并不一致,油管外壁以均匀腐蚀为主,腐蚀产物较少,尽管有一定的点蚀出现,但点蚀坑深度相对较浅,整体而言腐蚀较为轻微。相比之下,油管内壁表面覆盖有一层致密的腐蚀产物膜,膜下发生了较为严重的局部腐蚀,表面点蚀坑和微裂纹清晰可见,点蚀坑深度达约120 μm,容易诱发SCC,对其使用造成严重的威胁。

同时,为调查油田腐蚀环境中各因素与L80钢的电化学和应力腐蚀的关系,在实验室内分别进行了不同条件下的电化学阻抗谱、极化曲线测量和慢应变速率拉伸实验。结果显示,含水率为腐蚀过程中最为重要的环境因素,随着含水率的增加,阻抗弧半径急剧下降,腐蚀电流密度和腐蚀电位也急剧变化,表明其耐蚀性大大降低。更重要的是,SCC敏感性也随着含水率的增加而有所升高。虽然CO2和H2S对电化学过程产生了较为明显的影响,但在特定的含水率下,SCC行为几乎没有变化,SCC敏感性差异较小,表明L80钢在油田采出液环境中具有较好的耐SCC能力。

吉林油田腐蚀环境以油水混合液和CO2/H2S伴生气为主,腐蚀初期含水率及H2S含量不高时,外壁腐蚀轻微;随着服役时间的延长,含水率及H2S含量有所增加,环境介质腐蚀性加剧,导致一定程度点蚀坑的生成,并形成较少的腐蚀产物。由于油管钢外表面涂覆有一层黑色的保护膜,在静态环境下,油水混合液中的水分难以接触L80钢表面,而轻微的腐蚀又难以形成稳定的腐蚀产物层,整个外壁表面活性一致,始终以均匀腐蚀为主。

相比之下,L80油管钢内壁始终处于流动的油水混合液以及CO2/H2S伴生气环境中,尽管腐蚀介质与外壁差异不大,但是介质的流动导致离子交换速度加快,在腐蚀初期含水率以及H2S含量较低时,腐蚀速率在一定程度上也能加快,形成一些结构致密的腐蚀产物FeCO3和FeS,而且这些腐蚀产物与基体具有较好的粘附性。随着时间的推移,腐蚀产物堆积逐渐形成一层薄的腐蚀产物层,对基体起到一定的保护作用[18,19],降低腐蚀速率,这也可以从实验室内H2S组的电化学结果中看出。随着吉林油田开采时间的延长,CO2和次生的H2S含量急剧增加,含水率持续上升,最高达到85%,环境介质腐蚀性显著增强,在流动力的作用下,水分更易穿透腐蚀产物层并在其下诱发局部腐蚀。同时,CO2和H2S的增多带来更多的腐蚀介质,因而外部环境中的腐蚀性离子不断补充,局部腐蚀效应显著加强,形成更深的点蚀坑,甚至诱发微裂纹的形成[20,21,22,23]。然而,考虑到油田浸出液中含水量才是诱发SCC更为主要的因素,而油管取出时检测到的水含量达85%,说明含水量增加的空间不大,即对SCC行为的进一步影响较为有限。因此,综合来看,吉林油田中使用的L80钢对SCC具有较好的抵抗力,适合用于采油井油管材料,在使用过程中只需加强对L80油管钢的监测和检测,即可避免出现问题。

4 结论

(1) L80钢在吉林油田环境中服役一段时间后,其内外表面均发生一定程度的腐蚀,外壁腐蚀轻微,仅可见较浅的腐蚀坑;内侧腐蚀较为严重,出现了尺寸较深的蚀坑,同时还伴随有一定的微裂纹。

(2) 点蚀坑和SCC微裂纹均由含水率高的CO2/H2S环境引起,其中较高的含水率和流动的内部介质是引起其内表面腐蚀严重和出现裂纹的主要原因。

(3) 总体而言,所选用的L80钢在模拟油田采出液环境下具有较低的SCC敏感性,CO2和H2S等环境因素对其SCC行为影响较小,适合用于采油井油管材料。

参考文献

Review of CO2 corrosion and protection in oil and gas pipelines

[J].

油气管线的CO2腐蚀与防护综述

[J].

Corrosion behavior of N80 and 3Cr tubing steels in CO2 flooding environment

[J].

N80和3Cr油管钢在CO2驱油环境中的腐蚀行为

[J].

Effects of long term aging on microstructure and properties of heat insulation oil pipe steel

[J].

长期时效对一种隔热油管钢组织和性能的影响

[J].

The effects of temperature and pH on the characteristics of corrosion product in CO2 corrosion of grade X70 steel

[J].

Effects of CO2 partial pressure on CO2 corrosion behavior of N80 tubular steel

[J].

CO2分压对N80油管钢CO2腐蚀行为的影响

[J].

Effects of pH values on corrosive films characteristics and corrosive behaviors of super 13Cr tubing steels in NaCl solution

[J].

pH值对超级13Cr钢在NaCl溶液中腐蚀行为与腐蚀膜特性的影响

[J].

Effect of H2S partial pressure on stress corrosion cracking behavior of N80 oil casing steel in the environment of CO2

[J].

H2S分压对N80油套管钢CO2环境下应力腐蚀开裂的影响

[J].

Simulation of corrosion product activity in extended operating cycles of PWRs under flow rate transient and nonlinearly rising corrosion rates coupled with pH effects

[J].

The electrochemical behaviour of 2205 duplex stainless steel in alkaline solutions with different pH in the presence of chloride

[J].

Failure analysis of a natural gas pipeline

[J].

Failure analysis of corrosion at an inhomogeneous welded joint in a natural gas gathering pipeline considering the combined action of multiple factors

[J].

New understandings of hydrocarbon accumulation in Penglai 19-3 oilfield, the Bohai waters

[J]. Abstract: As the biggest oilfield discovered offshore China so far,the Penglai 19-3 oilfield has aroused constant debates on oil sources and characteristics of massivescale hydrocarbon accumulation in the late stage.From this study,we have brought up with three new understandings.First,oil in the Penglai 19-3 oilfield mainly originates from the source rocks in the Shahejie Formation and partially from source rocks in the Dongying Formation (in the Bozhong sag).Hydrocarbons charged reservoirs from two apparent directions,i.e.,the NW direction (from the Bozhong sag) and the SE direction (from the Miaoxi sag).The favorable factors for the development of the Penglai 19-3 oilfield are extremely abundant oil source in the Bozhong sag,longexisting lowpotential energy area and the energy release from the TanLu Fault as well as favorable carrier system dominated by unconformities.Third,The significant differences of interwell temperature,change patterns of oil density,viscosity and gases and largescale existence of “gas chimney” rooted in ocean floor reveal that this oilfield is obviously characterized by abundant hydrocarbon sources and late hydrocarbon accumulation.Oil charging is still intensive in the northern part of the field at present.All leads to the conclusion that the Penglai 19- oilfield is a typical massivescale,rapid hydrocarbon accumulation in the late stage in Bohai Sea. Key words: biomarker compounds,TanLu Fault,gas chimney,Neogene oil pool,hydrocarbon accumulation in the late stage,Penglai 19-3 oilfield,Bohai Sea New understandings of hydrocarbon accumulation in Penglai 19-3 oilfield,the Bohai waters Guo Yonghua,Zhou Xinhuai,Ling Yanxi,Li Jianping,Wang Feilong and Wang Jun (Exploration & Production Research Institute,Bohai Oilfield,CNOOC Tianjin Company,Tianjin 300452,China) Abstract: As the biggest oilfield discovered offshore China so far,the Penglai 19-3 oilfield has aroused constant debates on oil sources and characteristics of massivescale hydrocarbon accumulation in the late stage.From this study,we have brought up with three new understandings.First,oil in the Penglai 193 oilfield mainly originates from the source rocks in the Shahejie Formation and partially from source rocks in the Dongying Formation (in the Bozhong sag).Hydrocarbons charged reservoirs from two apparent directions,i.e.,the NW direction (from the Bozhong sag) and the SE direction (from the Miaoxi sag).The favorable factors for the development of the Penglai 19-3 oilfield are extremely abundant oil source in the Bozhong sag,longexisting lowpotential energy area and the energy release from the TanLu Fault as well as favorable carrier system dominated by unconformities.Third,The significant differences of interwell temperature,change patterns of oil density,viscosity and gases and largescale existence of “gas chimney” rooted in ocean floor reveal that this oilfield is obviously characterized by abundant hydrocarbon sources and late hydrocarbon accumulation.Oil charging is still intensive in the northern part of the field at present.All leads to the conclusion that the Penglai 19-3 oilfield is a typical massivescale,rapid hydrocarbon accumulation in the late stage in Bohai Sea.

渤海海域蓬莱19-3油田油气成藏特征新认识

[J].蓬莱19-3油田是中国近海海域迄今发现的最大油田,油气来源和晚期超大规模成藏研究是其发现以来地质家不断研究和争论的焦点。研究认为:1)蓬莱19-3油田原油主要源于沙河街组烃源岩,部分源于东营组(渤中凹陷为主)烃源岩。油田周边存在两个非常明显的油气充注方向,即:油田的北西方向(渤中凹陷)和东南方向(庙西凹陷)。2) 渤中凹陷极为丰富的油源、长期的低势区和郯庐断裂的能量释放以及以不整合面为主导输导体系的优势成藏模式是蓬莱19-3油田形成的先决条件。3) 油藏内部井间温度的显著差异、原油密度、粘度和气体的变化规律,以及直至海底的‘气烟囱’较大面积存在等,说明油藏油气源非常充足,油田北侧至今存在超强充注,晚期成藏特征明显。证实了蓬莱19-3油田是渤海海域一种典型的晚期大规模快速成藏类型。

Investigating the mechanism of stress corrosion cracking in near-neutral and high pH environments for API 5L X52 steel

[J].

Stress corrosion cracking behavior of 16 Mn steel and heat-affected zone in alkaline sulfide with different concentrations

[J].

不同硫化物浓度碱性溶液中16Mn钢及热影响区应力腐蚀行为

[J].利用U形弯试样浸泡实验和电化学技术研究了16Mn钢及其模拟热影响区在不同硫化物浓度的碱性(pH=11.7)介质中的应力腐蚀开裂(SCC)行为与机理。结果表明:16Mn钢原始组织、粗晶组织(空冷组织)和硬化组织(淬火组织)在碱性硫化物环境中均能形成保护性腐蚀产物膜、导致电极过程近似呈钝化状态,钝化电流密度依次降低;淬火组织析氢电流密度较高,腐蚀速度较低,长期服役后会造成靠近熔合线部分腐蚀深度大而暴露出残余拉应力区,引起SCC;HAZ中硬化组织、粗晶组织和原始组织在碱性硫化物环境下SCC敏感性逐渐降低,硬化组织具有较明显的SCC敏感性,粗晶组织和原始组织SCC敏感性小;硫化物浓度升高,16Mn钢及其模拟热影响区SCC敏感性增加;16Mn钢焊缝区在碱性硫化物环境中SCC裂纹扩展机制为阳极溶解机制。

Effect of cathodic protection on corrosion of pipeline steel under disbonded coating

[J].

Characterization of passive film on 2205 duplex stainless steel in sodium thiosulphate solution

[J].The electrochemical behaviour of passive film formed on 2205 duplex stainless steel in 0.1 M Na2S2O3 solutions was investigated using potentiodynamic polarization, EIS, Mott-Schottky analysis and the compositions of oxide film in different passive regions were carried out by XPS. The results indicated that the impedance is dependent on the applied potential indicating the occurrence of a charge transfer reaction in a porous film. The doping densities evaluated from Mott-Schottky plots demonstrated that there existence of two donor levels in the space charge layer of the passive films. The donor density (N-D1 and N-D2) values are in the range of 10(20)-10(21) cm(3), and decreases exponentially with increasing film formation potential, which is in good agreement with the theoretical consequences of the PDM. The polarization curve and XPS results shows that in the passive regions the 2205 duplex stainless steel exhibits different electrochemical and semiconductor properties. (C) 2011 Elsevier B.V.

Passivity of 316L stainless steel in borate buffer solution studied by Mott-Schottky analysis, atomic absorption spectrometry and X-ray photoelectron spectroscopy

[J].

Process control of reinforcement corrosion in concrete. Part 1: Effect of corrosion products

[J].

Corrosion behavior of E690 high-strength steel in alternating wet-dry marine environment with different pH values

[J].

Stress corrosion cracking behavior of X70 pipe steel in an acidic soil environment

[J].

Stress corrosion cracking of X80 pipeline steel in simulated alkaline soil solution

[J].

Effects of hydrogen-charging on the susceptibility of X100 pipeline steel to hydrogen-induced cracking

[J].